Waste pp raffia bag / nylon bag recycling machineThis500kg/hr dirty pp pe ldpe plastic film washing recycling line is designed and manufactured by MOOGE TECH, which is widely used for waste plastic PE / LDPE / LLDPE /PVB film, Stretch film, Agricultural film, PP woven bag, PP Jumbo bag, Cement bag, drip pipe irrigation etc.

The waste dirty material go through crushing, friction washer, washing, dewatering, hot air drying process will turn to be clean flakes for pelletizing.

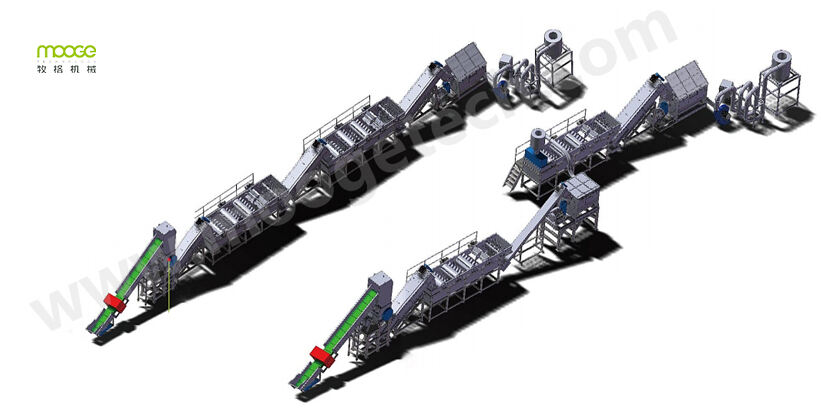

The line can be displayed "L" or "U" shape according to clients' workshop.

We can also customize the washing line components according to client's material and product requirement.

Model |

Capacity |

Installed Power |

Hot Washing |

Water Supply |

Area Required(L*W*H) |

ME-300 |

300 kg/hr |

200 kw |

Optional |

6-8 m3/hr |

40*4*5 m |

ME-500 |

500 kg/hr |

350 kw |

Optional |

8-10 m3/hr |

40*4*5 m |

ME-1000 |

1000 kg/hr |

600 kw |

Optional |

15-20 m3/hr |

55*6*6 m |

Single shaft shredder machine (for baled film/bag)

Put the whole bale film into the shredder, shredding material into small flakes

Crusher machine(for loose film/bag)

Crushing the film/bags into small pieces, wet working with water, can also choose shredder instead

Friction washer loader machine

Friction washing with water to remove the dirty and loading up material

Floating Washing Tank

Washing out the dirty from the film or bags material by paddles, tank material is made by SUS 304

Dewatering machine

Remove the water out from the material, machine contact the material is made by SUS304

Film squeezing pelletizing machineï¼optional)

Drying washed plastic film/bag and make it to granules

Hot Washing Tank(Optional)

With hot water and chemical reagent to washing off the oil, glue and dirty,machine contact the material is made by

SUS304

Pipe Drying System

With hot air further drying the material, machine contact the material is made by SUS304

We also supply PLASTIC PE FILM/PP BAGS PELLETIZING LINE (plastic granulator) to make the clean flakes into pellets (granules). The renewable pellets (granules) can be made into plastic barrel, plastic pipe, plastic frame, farm implement, machine components, and so on through extruding forming machine. They are widely used in agriculture, construction, industry and our daily life. In this way, we achieve the reuse of waste plastic recycling and the purpose of protecting our environment.

Plastic Film/Bags Washing Line

Plastic Film/Bags Washing Line

Plastic Film/Bags Washing Line

MOOGE

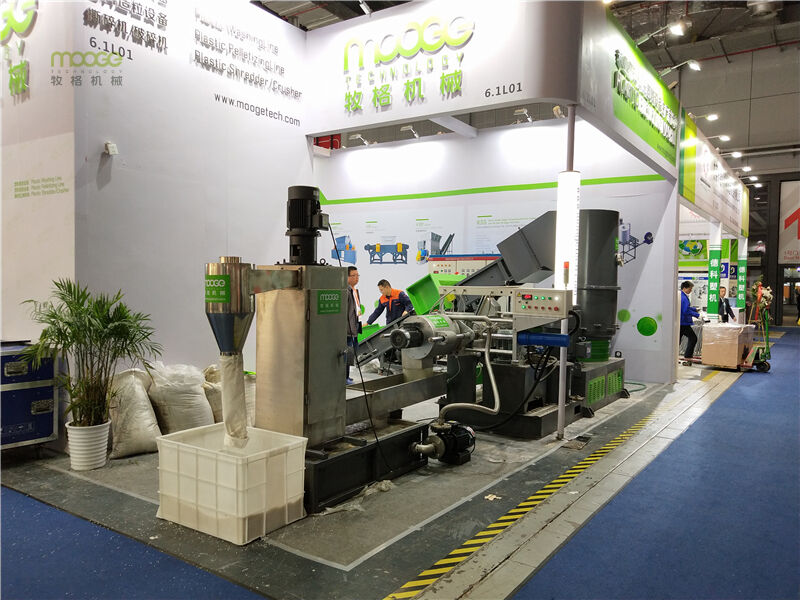

Looking for a reliable and efficient ways to recycle waste PP raffia bags or nylon bags? Look no further than the MOOGE Waste PP Raffia Bag / Nylon Bag Recycling Machine.

Made to manages many waste materials, including PP raffia bags, nylon bags, along with other comparable materials. This devices is built to delivers outstanding performances and long-lasting reliability with state-of-the-art technology and top-quality elements.

One of the standout features of the MOOGE recycling devices is its ability to quickly process waste materials and efficiently. This method can very quickly and accurately separates several types of waste materials, making it perfect for high-volume recycling operations having a high-capacity shredders and advanced sorting equipments.

Other key features of the MOOGE Waste PP Raffia Bag / Nylon Bag Recycling Machine include:

- Easy operation and user-friendly controls

- Advanced dust collection and purification systems to ensure clean, safe processing

- High-quality, heavy-duty construction for maximum durability and longevity

- Simple, modular design for easy maintenance and repair

If you're looking for a top-quality, reliable recycling solutions for waste PP raffia bags, nylon bags, and other similar materials, you can't go wrong with the MOOGE Waste PP Raffia Bag / Nylon Bag Recycling Machine. With its advanced features, outstanding performances, and exceptional values, this systems is the perfect choices for any recycling operation that demands the best. So why wait? Invest in the MOOGE Recycling Machine today and start transforming wastes into valuable new resources.

×

×