×

×

Model |

Capacity |

Installed Power |

Hot Washing |

Water Supply |

Area Required(L*W*H) |

ME-300 |

300 kg/hr |

200 kw |

Optional |

6-8 m3/hr |

40*4*5 m |

ME-500 |

500 kg/hr |

350 kw |

Optional |

8-10 m3/hr |

40*4*5 m |

ME-1000 |

1000 kg/hr |

600 kw |

Optional |

15-20 m3/hr |

55*6*6 m |

MOOGE

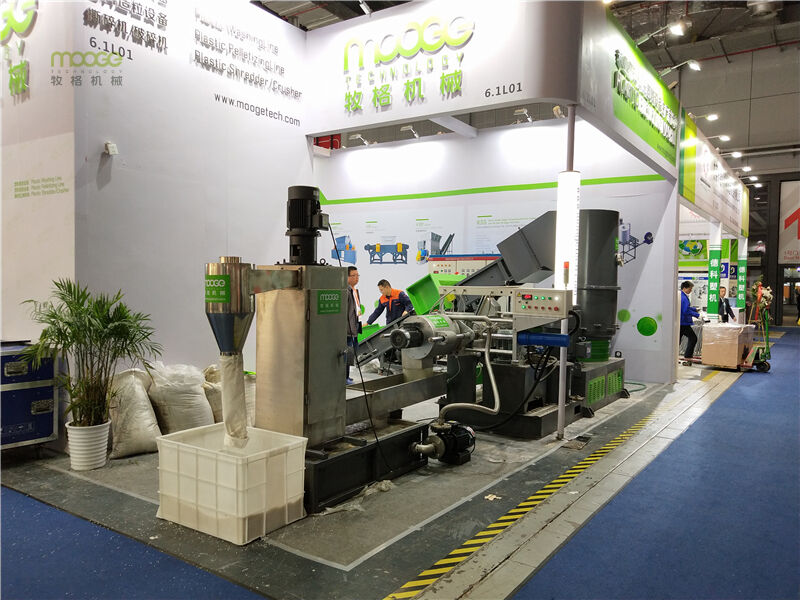

If you are searching for an ingenious environmentally friendly method towards handle plastic squander, have a look at the Bag Cleaning Reusing Collection PP Non Interweaved Material / Plastic Production Vegetation coming from MOOGE TECH. This incredible item enables you towards recycle plastic bags non-woven material in an effective lasting method, decreasing the ecological effect of these products assisting you conserve cash on squander administration.

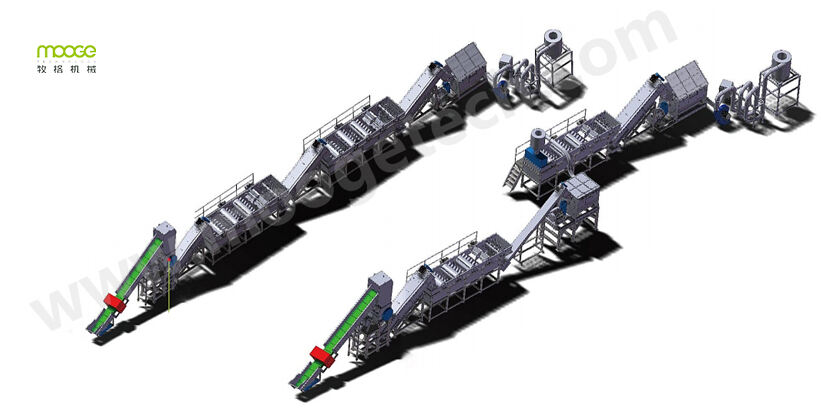

Created to become a simple job towards run preserve, through possessing a user interface is easy to use allows you towards customize the treatment towards satisfy your specific requirements. This gadget are developed for big quantities of plastic squander, creating it perfect for industrial commercial requests along with a ability variety of 300 towards 1500 kgs every hour.

Comprehended for reliability high top premium, the Bag Cleaning Reusing Collection PP Non Interweaved Material / Plastic Production Vegetation is no exemption. Developed along with costs products elements, this gadget is developed towards final can easily endure utilize is hefty severe problems. The MOOGE Bag Cleaning Reusing Collection PP Non Interweaved Material / Plastic Production Vegetation is a wise financial assets whether you are attempting to start a reusing business or even just wish to decrease your environmental impact.

Among the essential functions of this particular item is its own capability towards clean different different kinds of plastic, consisting of PP (polypropylene) material is non-woven. It is an factor to consider is essential lots of companies, as various kinds of plastic need various handling methods. Along with the Bag Cleaning Reusing Collection PP Non Interweaved Material / Plastic Production Vegetation, it is feasible towards procedure several kinds of plastic simultaneously, conserving opportunity effectiveness is enhancing.

An extra profit is its own modular style. This allows you include or even eliminate aspects as required, depending upon your demands being particular. You have the ability to perform for that reason quickly cost-effectively using this gadget whether you have to enhance ability, enhance high top premium, or even personalize the procedure in various other implies.

The MOOGE Bag Cleaning Reusing Collection PP Non Interweaved Material / Plastic Production Vegetation is a remarkable item that provides a lasting effective method towards handle plastic squander. Along with its own top quality building, easy to use user interface, capability variety of 300 towards 1500 kgs every hour, modular style, this device is a suitable option for companies wanting to decrease their ecological effect enhance their profits. Therefore why hang around? Get in touch with MOOGE TECH today to find out more around this incredible item exactly how it can easily profit your company.