×

×

Economic Type Recycling Line |

||||||||||

Model |

Capacity |

Installed power |

Hot Washing |

Water Supply |

Area Required(L*W*H) |

|||||

ME-300 |

300 kg/h |

150kw |

Optional |

4-5 m3/hr |

24*4*5m |

|||||

ME-500 |

500 kg/h |

225kw |

Optional |

6-8 m3/hr |

25*4*4m |

|||||

Advance Type Recycling Line: |

||||||||||

Model |

Capacity |

Installed Power |

Hot Washing |

Water Supply |

Area Required(L*W*H) |

|||||

ME-300 |

300 kg/hr |

200 kw |

Optional |

6-8 m3/hr |

40*4*5 m |

|||||

ME-500 |

500 kg/hr |

350 kw |

Optional |

8-10 m3/hr |

40*4*5 m |

|||||

ME-1000 |

1000 kg/hr |

600 kw |

Optional |

15-20 m3/hr |

55*6*6 m |

|||||

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

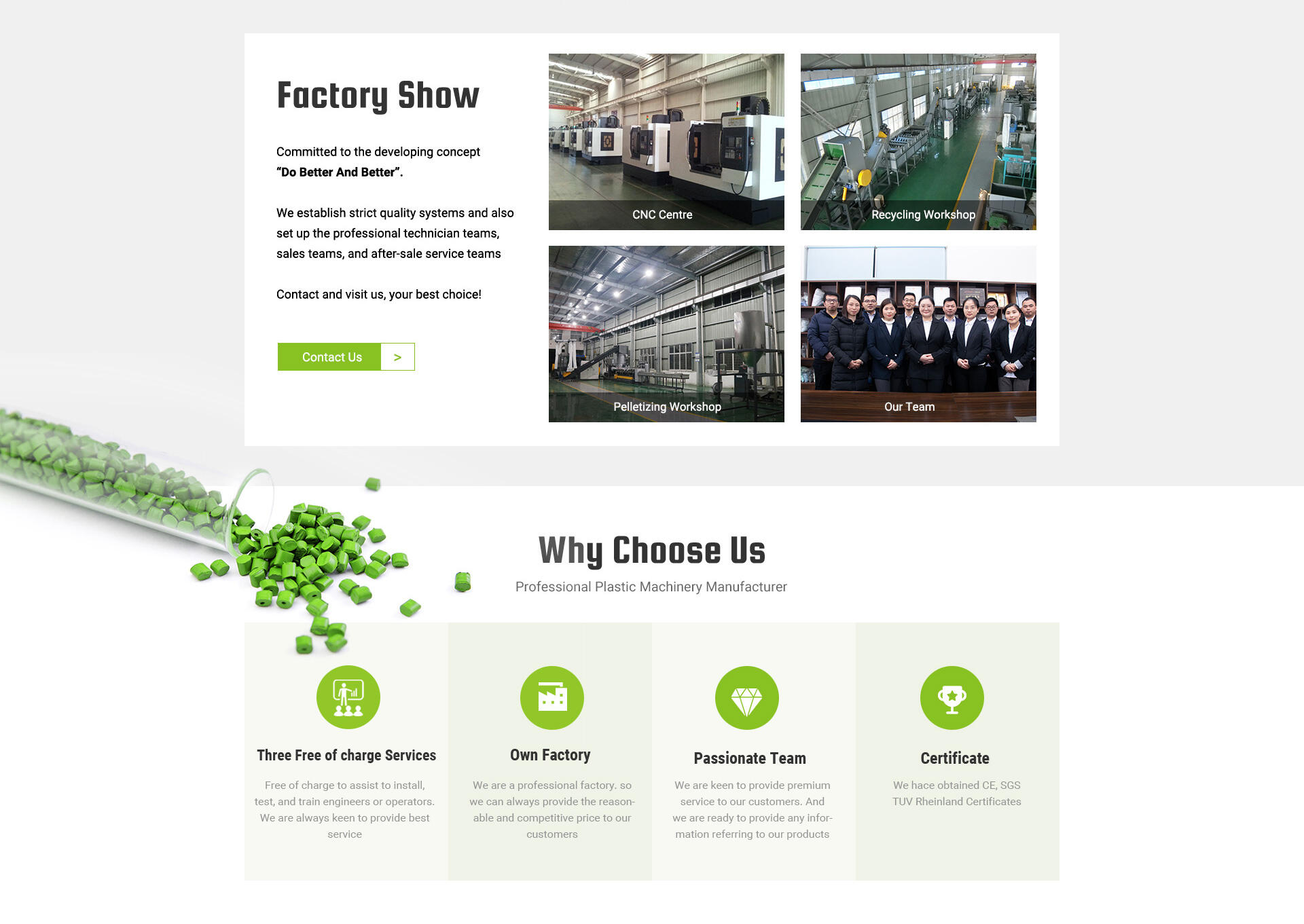

MOOGE

The Plastic PP PE Movie Recycle Cleaning Collection is the ideal service for people that are searching for an efficient method recycle their plastic movies. This item is skillfully developed towards accommodate the distinct requirements of various markets, consisting of the agricultural, health care markets, product packing. The MOOGE has produced this item along with the most recent innovation towards ensure top quality outcomes each time.

Includes extremely effective devices that manage the implies of cleaning splitting products that are plastic. The device will get you with the whole procedure of separating plastic is big products right in to smaller sized items. The tip is following cleaning the plastic pieces towards get rid of any type of dust, gunk, or even pollutants. The cleaning procedure is outstanding because the device brings away the procedure rapidly totally.

Functions a cutting edge clothes dryer that guarantees that the artificial is cleaned are completely dried out. The technique is drying out crucial because it avoids any type of microbial development guarantees that the plastic pieces are ready to become utilized. After the procedure is drying out finish, the gadget will after that carry out a arranging procedure, where the plastic products are divided based upon their dimension kind.

Ensured that the gadget is simple towards preserve use. The device is easy to use, the producers have provided an handbook is training guarantee that you have the ability to run the device with no issues. Furthermore, the equipment's upkeep are simple, lots of because of the products that are high-quality in production it. The products are durable can easily endure problems that are severe for that reason the device will final for years when set up.

Could be an service is eco-friendly decreases squander assisting safeguard the world. It is perfect for each small massive companies, making it a financial assets is flexible. Furthermore, the product is inexpensive provides worth for cash in the operate is long.

The Plastic PP PE Movie Recycle Cleaning Collection is a game-changers in the plastics market. The MOOGE brand names has developed this items along with the most recent innovation top quality products towards guarantees that it offers a service towards plastic squander without jeopardizing on the high top premium of the reused plastic products. Acquisition this items today enter into the services towards plastic squander.