×

×

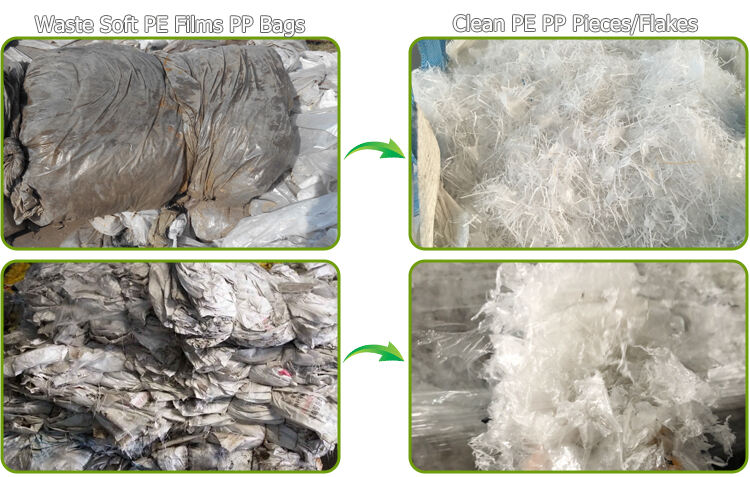

Do you have a lot of waste plastic film and jumbo bags lying around and don't know what to do with them? Introducing the MOOGE Waste Pe Ldpe Plastic Film Pp Jumbo Woven Bag Crushing Washing Line, the perfect solution to your plastic waste problem.

This product that is high-quality built to handles all sorts of plastic wastes, from LDPE and PP film to jumbo woven bags. Using its advanced crushing and technology that is washing it is possible to recycle these materials and turns them into reusable plastic pellets.

Created from durable materials that will withstand use that is heavy. It has a washing that is high-speed dehydration system that can process as much as 1500kg of plastic waste each hour, which makes it perfect for companies and organizations that produce a lot of plastic wastes.

The product is user friendly and can be operated by anybody, even those with no previous experience with plastic technology that is recycling. It features a screen that is user-friendly allows you to set the parameters for the crushing and washing process, and it comes down with detailed directions that show you through every action of the processes.

An solutions that is environmentally friendly plastic waste. By recycling your plastic waste, you are helping to reduce the quantity of plastic that ends up in landfills, oceans, along with other habitats which can be natural. This can help to protect the environment and preserve the planet for generations to comes.

Order your Waste Pe Ldpe Plastic Film Pp Jumbo Woven Bag Crushing Washing Line from MOOGE today and starts recycling your plastic wastes like a pro.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

ME-300 |

300kg/hr |

190KW |

4-6m³/hr |

40*4.5*5m |

ME-500 |

500kg/hr |

260KW |

6-8m³/hr |

40*4.5*5m |

ME-1000 |

1000kg/hr |

500KW |

8-10m³/hr |

50*5*5.5m |

Item |

Specification |

Raw Material |

Waste Soft Plastic PE film, HDPE film, PP woven bags, PP film, PP jumbo bags, etc |

Finished Product |

Clean dry plastic flakes (size can be recycled as buyer request) |

Main Machine List |

Belt Conveyor, Shredder, Crusher, Cold Washing Tank, High Speed Friction Washer, Hot Washing Tank, Centrifugal Dryer, Hot Air Pipeline, Packing Silo |

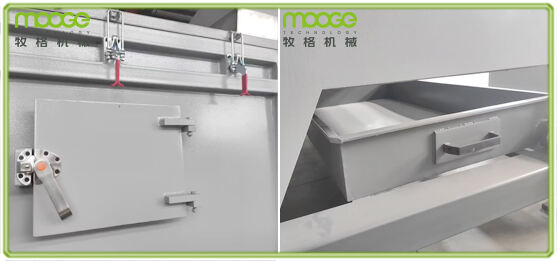

Machine Material |

Machine frame is made by carbon steel, the machine washing part is made by SUS 304 |

Main Components |

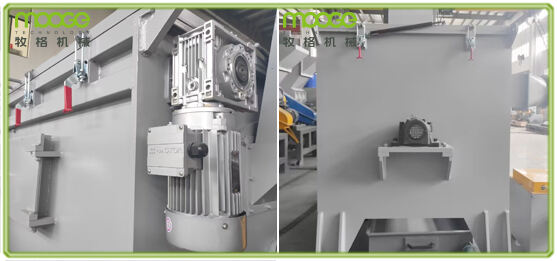

NSK/SKF bearing, TTO oil sealing, Guomao reducer,etc. |

Electric Components |

ABB/Delta inverter, Omron temperature meter, Schneider contactor, Chint switch, Siemens made in China motor, etc. |

Warranty Period |

One Year from the Machine Operation within 18 Months from the B/L Date |

Turnkey After Service |

Technical Support including the machine layout, electric diagram, working manual, engineer available to buyer's factory overseas for helping installation, commissioning, training workers, etc. consumable parts provided; 24-hours online after sale service; |