×

×

Model |

Capacity (kg/hr) |

Strap Size(mm) |

Installed Power(KW) |

Man power |

SJ65/33 Single Strap |

50-60 |

9-19 |

85 |

2 |

SJ75/33 Single Strap |

80-100 |

9-19 |

100 |

2 |

SJ75/33 Double Strap |

80-120 |

9-19 |

110 |

2 |

SJ90/33 Double Strap |

150-200 |

9-19 |

150 |

2 |

SJ120/33 Triple Strap |

200-250 |

9-19 |

220 |

2 |

MOOGE

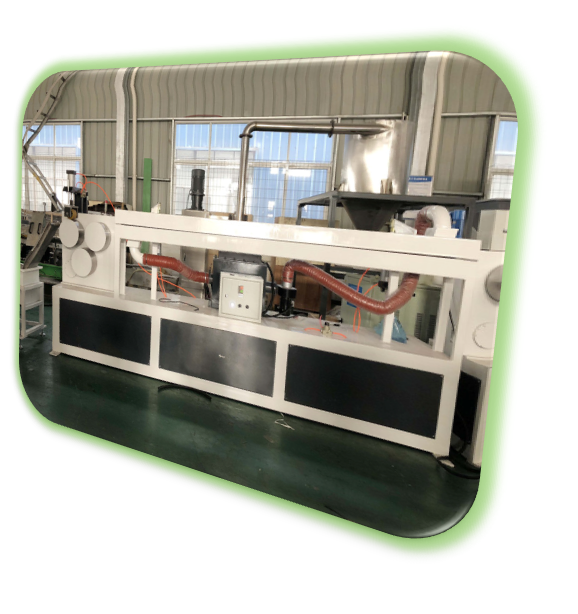

Introducing the Technically Reformed Plastic PP Strap Band Production Line from MOOGE - your ultimate solution for efficient and cost-effective strapping of goods. With a global reputation for developing cutting-edge plastic processing equipment, MOOGE has once again raised the bar with this innovative production line.

Built to cater to many companies, this is unparalleled precision, and durability. Designed with advanced level technology, this line is with the capacity of creating polypropylene is high-qualityPP) strap bands at an impressive speed that may easily maintain contemporary manufacturing demands.

This employs a user interface is user-friendly optimized control system, allowing for simple procedure and upkeep. The machine is integrated with an tension is automated mechanism that insures constant strap tension during the packing procedure, reducing the possibility of injury to goods in transportation significantly.

A solution is versatile can produce band bands in a variety of sizes and thicknesses. Having a design is flexible it allows users to personalize and adjust the production process in accordance with their particular requirements, further increasing its effectiveness and practicality. Furthermore, the line is capable of producing bands that are strap up to four colors, rendering it perfect for branding and identification purposes.

Can be an alternative is eco-friendly traditional strapping methods. Our polypropylene strap bands are completely recyclable and will be reused times that are numerous further reducing the carbon impact of the production operations.

At MOOGE, we have confidence in providing top-notch equipment to our customers that will meet their particular needs, and this isn't any exception. With decades of experience and a state-of-the-art manufacturing facility, we've developed a reputation for providing value-driven solutions that deliver performance is exemplary dependability.

In conclusion, the Technically Reformed Plastic PP Strap Band Production Line from MOOGE is a game-changer in the strapping industry, offering complete and versatile strapping solutions that can elevate your manufacturing operations to a whole new level. Invest in this technologically advanced production line today and experience a new level of productivity, efficiency, and sustainability.