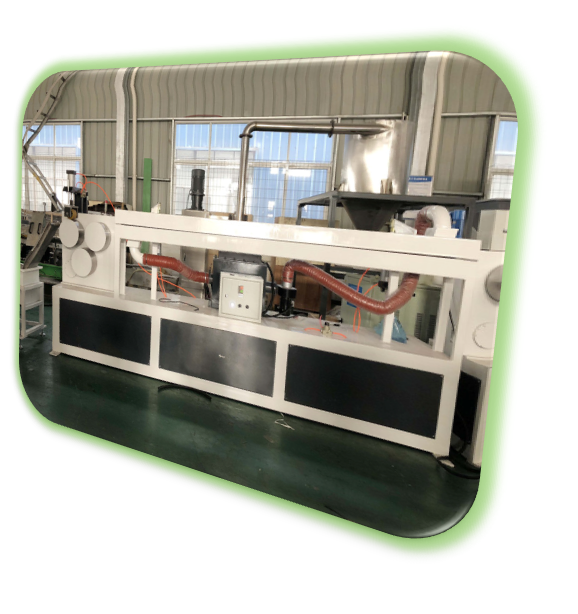

PET PP Strap Production Line

PET PP strap is recognized a new environment protective strapping material to substitute for Steel Strap &PP Strap in the ruling international market.

They are not only the aggregation of the intensity and the tenacity of steel strap, but also overcome the disadvantage of the tradition packing material such as insufficient intensity, brittle and so on. At present, they have been applied in wood, steel, and so on.

Our company this line adopt the PLC control the whole line do the automatic production. It use the melting pump and pressure sensor ensure the production stable and strap quality control.

The raw material you can use 100% recycled PET flakes from the waste PET bottles, or virgin material or mixed with each other.

Advantages1-Use 100% recycled PET flakes to reduce the cost

2-Good dehumidifier drying system to ensure the material equal dry to produce high quality strapping

3-Special design hot forming tensile tank to make good forming, equal width, straight strap.

Technical parameter

Model |

|

|

|

Man power |

SJ65/33 Single Strap |

|

|

|

|

SJ75/33 Single Strap |

|

|

|

|

SJ75/33 Double Strap |

|

|

|

|

SJ90/33 Double Strap |

|

|

|

|

SJ120/33 Triple Strap |

|

|

|

|

Pre-drying the PET flakes crystallization so it can increase the drying speed and line capacity

Honeycomb model

Inside made by Stainless steel

Screw made by 38CrMnAIA with nitriding treatment

Strap shape molding, the size and thickness can adjustable

Motor speed adjust by inverter

Hot Air Circulation Oven Machine

With the air blower cycling the hot air for full and equal heating up

With cooling forming tank

With length meter to calculate the length an automatic change disc

SJ75/33 Strap in Malaysia

Service Before Sale1. 24 hours online. Your inquiry will be quick reply by email.

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free.

If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you

request. We will tell you the tracking number after delivery.

Service After Sale1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

MOOGE

The PP Machinery Strap Belt Production Line is a high-quality solution for businesses looking to produce strong, durable strap belts. Made from polypropylene, these strap belts are heat-resistant, weather-resistant and have excellent tensile strength.

Carries a completely automated system for producing band belts, from melting and shaping the raw polypropylene to cutting and winding the item is last. This production line is just a valuable asset for companies that require to produce high volumes of strap belts on a consistent foundation by having a design that minimizes waste and maximizes efficiency.

Created to final, with durable components that may withstand the rigors of heavy use. Featuring a software is user-friendly intuitive settings, this manufacturing line is straightforward to use even for individuals who might not have substantial experience with this specific sort of equipment.

With MOOGE's PP Machinery Strap Belt Production Line, companies can produce strap is high-quality that meet their exact specs. This manufacturing line is versatile enough to meet up with an array of requirements whether you'll need band belts for packaging, delivery, or other applications.

Fashioned with safety in mind in addition to its impressive capabilities. With higher level safety features and security is comprehensive, organizations can feel confident that their staff is likely to be protected while using the this equipment.

Overall, the MOOGE PP Machinery Strap Belt Production Line is a reliable and efficient solution for businesses that need to produce high-quality strap belts on a consistent basis. With its advanced automation technology, intuitive controls, and durable construction, this production line is a valuable asset for any business looking to increase productivity and streamline their operations.

×

×