×

×

Introducing the MOOGE Plastic PET Recycling Plant PET Strap Making Machine / PET Package Strap Band Extrusion Line, a revolutionary technology that converts waste materials into high-quality PET straps and bands. This innovative machine is designed to provide a sustainable solution for plastic recycling, and help industries reduce their carbon footprint.

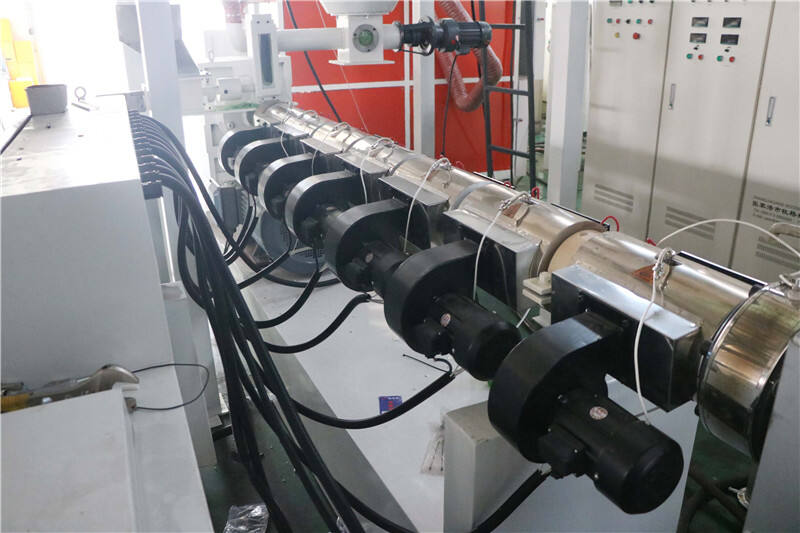

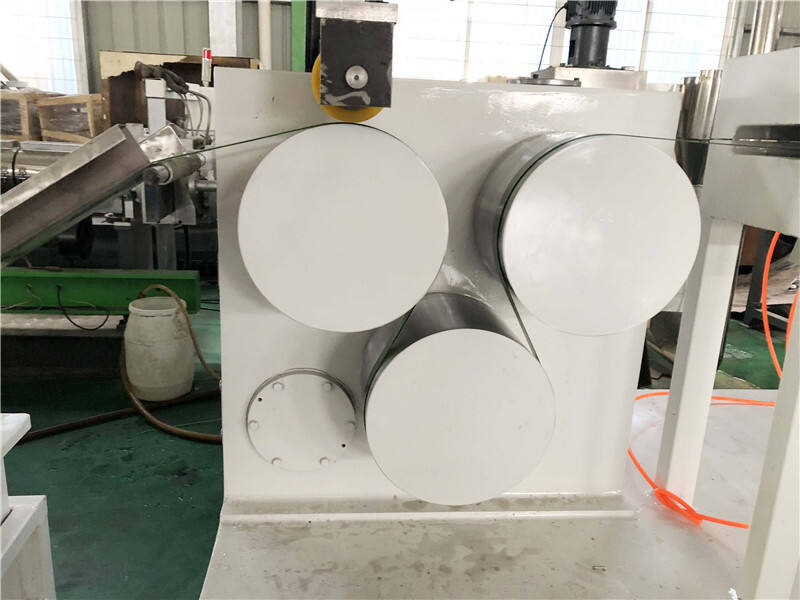

Features a completely automated process that converts wastes that is plastics as PET containers, into high-quality PET straps. The process that is entire energy-efficient, cost-effective, and easy to work. The PET strap machine that is making advanced extrusion technology to make a consistents and top-quality products that may be used for a variety of applications, including packaging, delivery, and manufacturing.

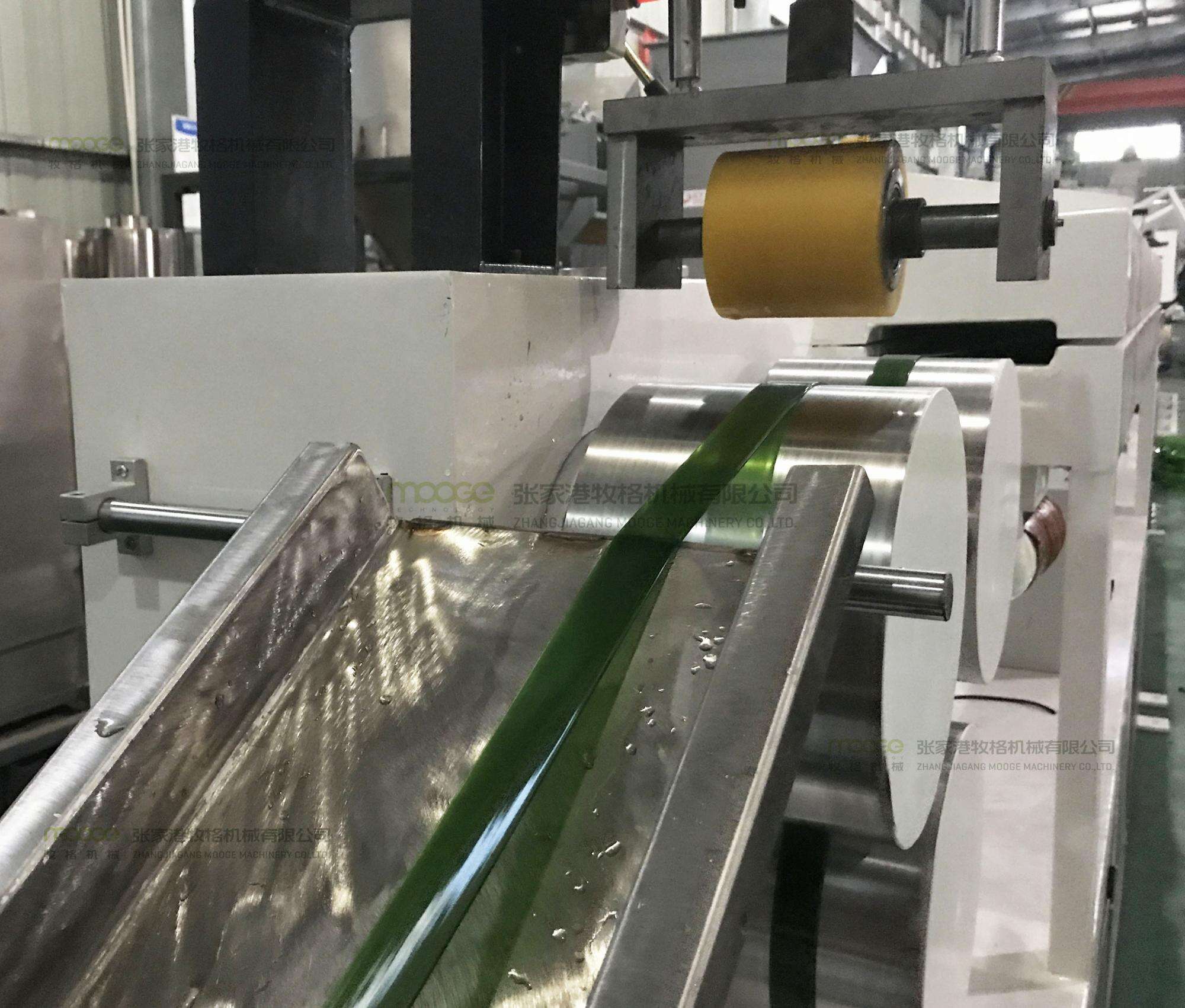

One of many most features being significant its versatility. The machines can produced PET straps in various widths and thicknesses to generally meets the specific requirements of different industries. Additionally, the device can also produce PET that is colored, providing clients with an array of modification options.

Another aspect that is crucial its high production capacity. The machine has an easy production speed, which allows it to produce large quantities of PET straps in a period that is short. This feature is particularly beneficial for industries that want a volume that is high of materials.

Furthermore, this was created to be environmentally friendly. The machine reduces the total amounts of plastic waste that ends up in landfills, hence causing a cleaner and healthiest environment by utilizing waste plastic materials. Additionally, the device reduces the importance of raw materials, which helps to store resources which can be natural preserve the earth.

Invests in the MOOGE Plastic PET Recycling Plant PET Strap Making Machine / PET Package Strap Band Extrusion Line today, and say hello to a sustainable futures.

1.use 100% recycled pet flakes to reduce the cost

2.good dehumidifier drying system to ensure the material equal dry to produce high quality strapping

3.special design hot forming tensile tank to make good gorming,euqal width,straight strap.

Model | Capcity (kg/h) | Strap Size | Power(kw) | Manpower | Area(m) |

SJ65/33 Single | 50-60 | 9-19mm | 85 | 1-2 | 35×4×5 |

SJ75/33 Single | 80-100 | 9-19mm | 100 | 1-2 | 38×4×6 |

SJ75/33 Duble | 80-120 | 9-19mm | 110 | 1-2 | 40×4×6 |

SJ90/33 Double | 120-150 | 9-19mm | 150 | 1-2 | 45×5×7 |

SJ120/33 Double | 150-200 | 9-19mm | 220 | 1-2 | 45×5×7 |