×

×

MOOGE

Plastic Waste Recycling Machine is the perfect solution for reducing and reusing plastic waste in a method is eco-friendly. This machine is made to recycle numerous kinds of plastic waste, including bottles, jars, containers, bags, and films.

The MOOGE Plastic Waste Recycling Machine is really a completely automated system that streamlines the recycling process and minimizes work expenses. It comes with a shredder, a crusher, a sealer, and a blender, that can come together to sort, shred, and melt waste is plastic pellets are reusable. These pellets can be used to produce a range is wide of, from synthetic bags to toys and furniture.

An ability is had by this recycling machine all the way to 2,000 kg each hour, making it perfect for large-scale operations. It is also energy-efficient, with a power is low of just 200 kW/h. This implies you cash on energy bills while allowing you to reduce your carbon footprint it could save yourself.

The MOOGE Plastic Waste Recycling Machine is easy to use and maintain. It comes down constructed with a user interface is user-friendly enables you to monitor and acquire a grip regarding the recycling procedure. The machine normally made for effortless cleansing and upkeep, with detachable components that will be quickly and effortlessly replaced.

One of many standout top features of the MOOGE Plastic Waste Recycling Machine is its safety features. Safety sensors to its built that prevent accidents and also make sure that the equipment runs efficiently. It also possesses an emergency stop button which allows one to quickly stop the machine in case there is any issues.

The MOOGE Plastic Waste Recycling Machine is just a versatile and solution is reliable will allow you to reduce your ecological impact. It is appropriate used in a number of companies, including production, packaging, and retail. This product could be the perfect investment for almost any business wanting to tend to be more sustainable alongside its higher level technology and design is revolutionary.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

ME-300 |

300kg/hr |

190KW |

4-6m³/hr |

40*4.5*5m |

ME-500 |

500kg/hr |

260KW |

6-8m³/hr |

40*4.5*5m |

ME-1000 |

1000kg/hr |

500KW |

8-10m³/hr |

50*5*5.5m |

Item |

Specification |

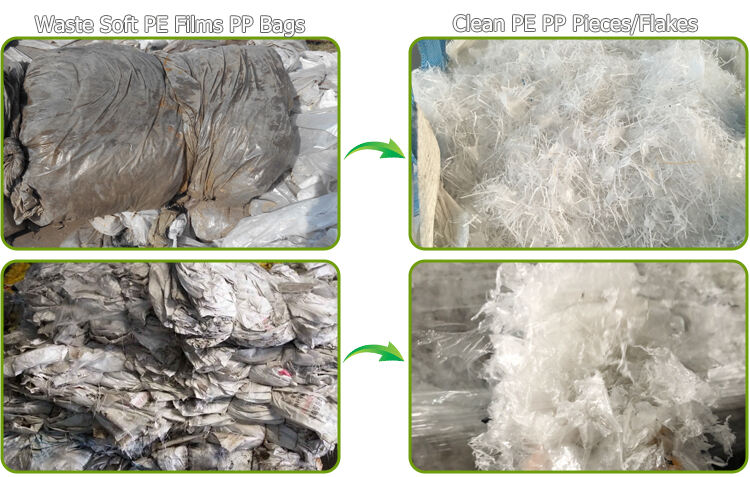

Raw Material |

Waste Soft Plastic PE film, HDPE film, PP woven bags, PP film, PP jumbo bags, etc |

Finished Product |

Clean dry plastic flakes (size can be recycled as buyer request) |

Main Machine List |

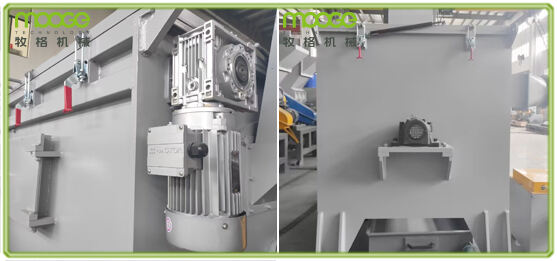

Belt Conveyor, Shredder, Crusher, Cold Washing Tank, High Speed Friction Washer, Hot Washing Tank, Centrifugal Dryer, Hot Air Pipeline, Packing Silo |

Machine Material |

Machine frame is made by carbon steel, the machine washing part is made by SUS 304 |

Main Components |

NSK/SKF bearing, TTO oil sealing, Guomao reducer, etc. |

Electric Components |

ABB/Delta inverter, Omron temperature meter, Schneider contactor, Chint switch, Siemens made in China motor, etc. |

Warranty Period |

One Year from the Machine Operation within 18 Months from the B/L Date |

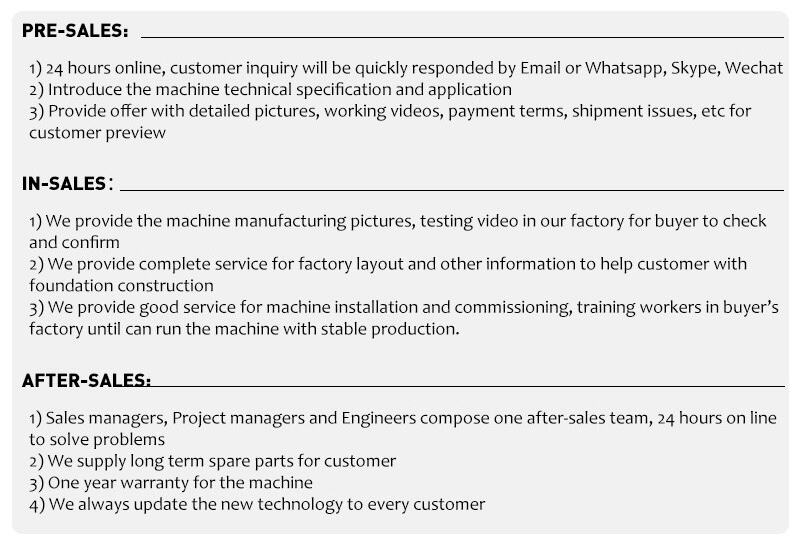

Turnkey After Service |

Technical Support including the machine layout, electric diagram, working manual, engineer available to buyer's factory overseas for helping installation, commissioning, training workers, etc. consumable parts provided; 24-hours online after sale service; |

• What material do you want to recycling? PE film/PP bag? HDPE/PP bottle? PET bottles? Or other plastic?

• What capacity (kg/h) do you want? Such as 500kg/hr or 1000kg/hr?

• What is the final size (mm) of flakes you want?

• Other special requirements about the Recycled Waste Plastic Crushing Recycling Machine Soft Film Plastic Recycling Machines if you have?