PET Strap Production Line

PET strap is recognized a new environment protective strapping material to substitute for Steel Strap &PP Strap in the ruling international market. They are not only the aggregation of the intensity and the tenacity of steel strap, but also overcome the disadvantage of the tradition packing material such as insufficient intensity, brittle and so on. At present, they have been applied in wood, steel,and so on.

Our company this line adopt the PLC control the whole line do the automatic production. It use the melting pump and pressure sensor ensure the production stable and strap quality control;

The raw material you can use 100% recycled PET flakes from the waste PET bottles, or virgin material or mixed with each other;

Advantages1-Use 100% recycled PET flakes to reduce the cost

2-Good dehumidifier drying system to ensure the material equal dry to produce high quality strapping

3-Special design hot forming tensile tank to make good forming, equal width, straight strap.

Technical parameter

Model |

|

|

|

Man power |

SJ65/33 Single Strap |

|

|

|

|

SJ75/33 Single Strap |

|

|

|

|

SJ75/33 Double Strap |

|

|

|

|

SJ90/33 Double Strap |

|

|

|

|

SJ120/33 Triple Strap |

|

|

|

|

Pry-Drying Tower

Pre-drying the PET flakes crystallization so it can increase the drying speed and line capacity

Dehumidifier Machine

Honeycomb model

Inside made by Stainless steel

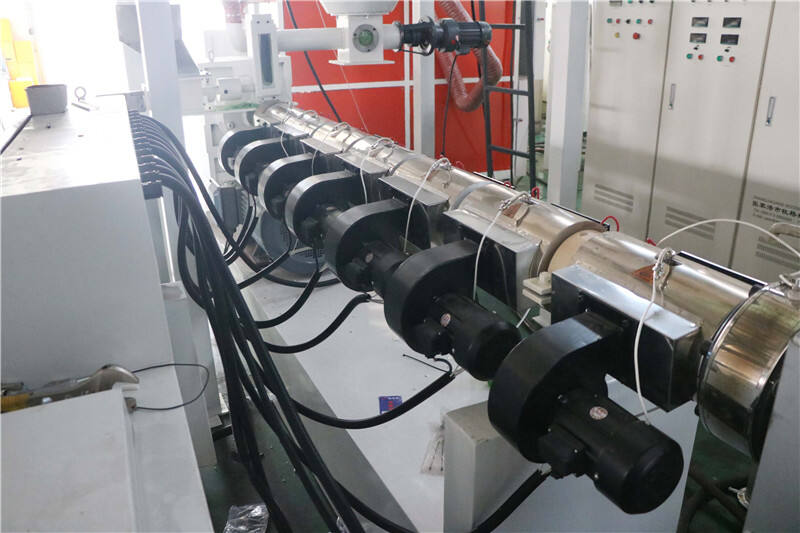

Single screw extruder

Screw made by 38CrMnAIA with nitriding treatment

Die mold

Strap shape molding, the size and thickness can adjustable

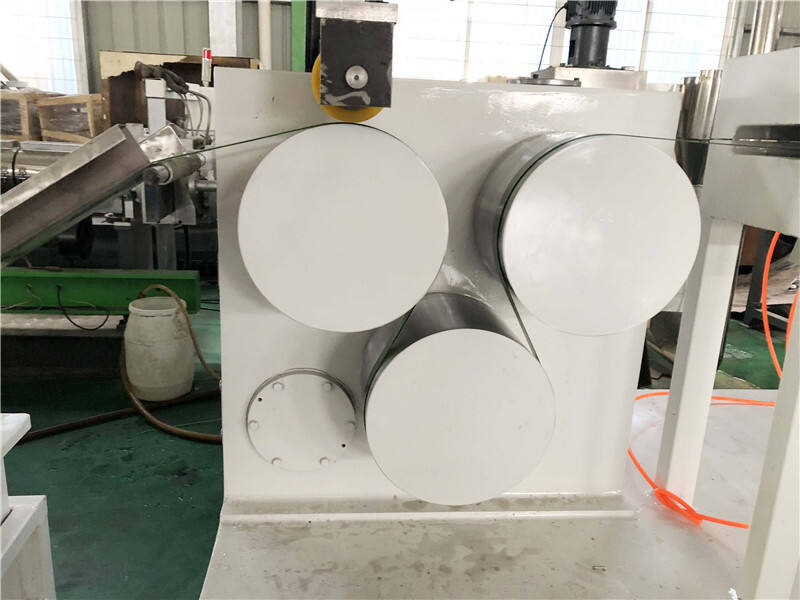

Haul-off machine

Motor speed adjust by inverter

Hot air circulation oven machine

With the air blower cycling the hot air for full and equal heating up

Stress relief machine

With cooling forming tank

Automatic winder machine

With length meter to calculate the length an automatic change disc

Raw material:Clean PET flakes

SJ75/33 Strap in Malaysia

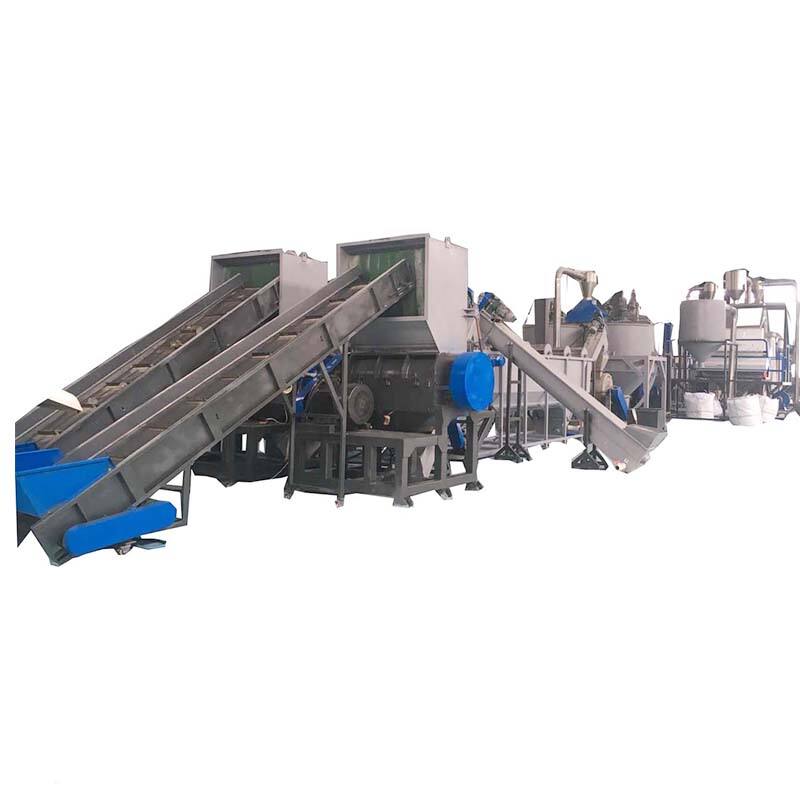

Waste plastic PET bottle washing recycling machine

Service Before Sale1. 24 hours online. Your inquiry will be quick reply by email.

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free.

If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you

request. We will tell you the tracking number after delivery.

Service After Sale1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

MOOGE

Presenting the Higher Efficiency PP PET Flakes Band Manufacturing Band Packaging Device Collection coming from MOOGE. This effective band assembly line is ideal for companies wanting to improve their packaging enhance efficiency procedure.

Produced along with high-quality products innovation is progressed guaranteeing higher resilience efficiency. The device is created towards produce solid efficient bands, making it the service is ideal product packing hefty products like for example structure products, commercial much a lot extra, equipment.

Created along with PP PET flakes, an excellent, resilient, light-weight item is actually ideal for strapping. The ability is possessed due to the devices towards procedure as long as 3000kg each hour, creating it perfect for high-volume production demands.

Consists of the majority of the required equipment towards produce plastic strapping, consisting of a shredder, extruder, body is cooling down. The shredder decreases the pet flakes right in to little bit of items, which are after that succumbed to the extruder. The extruder heats up melts the plastic, before it being required through a pass away towards produce the band. The cooling down body after that rapidly cools establishes the band, guaranteeing it has a soft surface is constant.

Totally automated, getting rid of the requirement for manual function decreasing the opportunity of private error. Drivers can easily extremely rapidly command the production procedure coming from a body is main guaranteeing free throw line runs effectively. Likewise, the devices includes security functions, consisting of dilemma point switches, towards guarantee the security of drivers.

Simple towards established maintain preserving, along with very little downtime needed for repair work maintenance. The device was produced towards endure the roughness of everyday use, guaranteeing efficiency is resilient.

Purchase the MOOGE Higher Efficiency PP PET Flakes Band Manufacturing Band Packaging Device Collection today expertise the advantages of a much more effective efficient packaging procedure.

×

×