×

×

Economic Type Recycling Line |

||||||||||

Model |

Capacity |

Installed power |

Hot Washing |

Water Supply |

Area Required(L*W*H) |

|||||

ME-300 |

300 kg/h |

150kw |

Optional |

4-5 m3/hr |

24*4*5m |

|||||

ME-500 |

500 kg/h |

225kw |

Optional |

6-8 m3/hr |

25*4*4m |

|||||

Advance Type Recycling Line: |

||||||||||

Model |

Capacity |

Installed Power |

Hot Washing |

Water Supply |

Area Required(L*W*H) |

|||||

ME-300 |

300 kg/hr |

200 kw |

Optional |

6-8 m3/hr |

40*4*5 m |

|||||

ME-500 |

500 kg/hr |

350 kw |

Optional |

8-10 m3/hr |

40*4*5 m |

|||||

ME-1000 |

1000 kg/hr |

600 kw |

Optional |

15-20 m3/hr |

55*6*6 m |

|||||

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

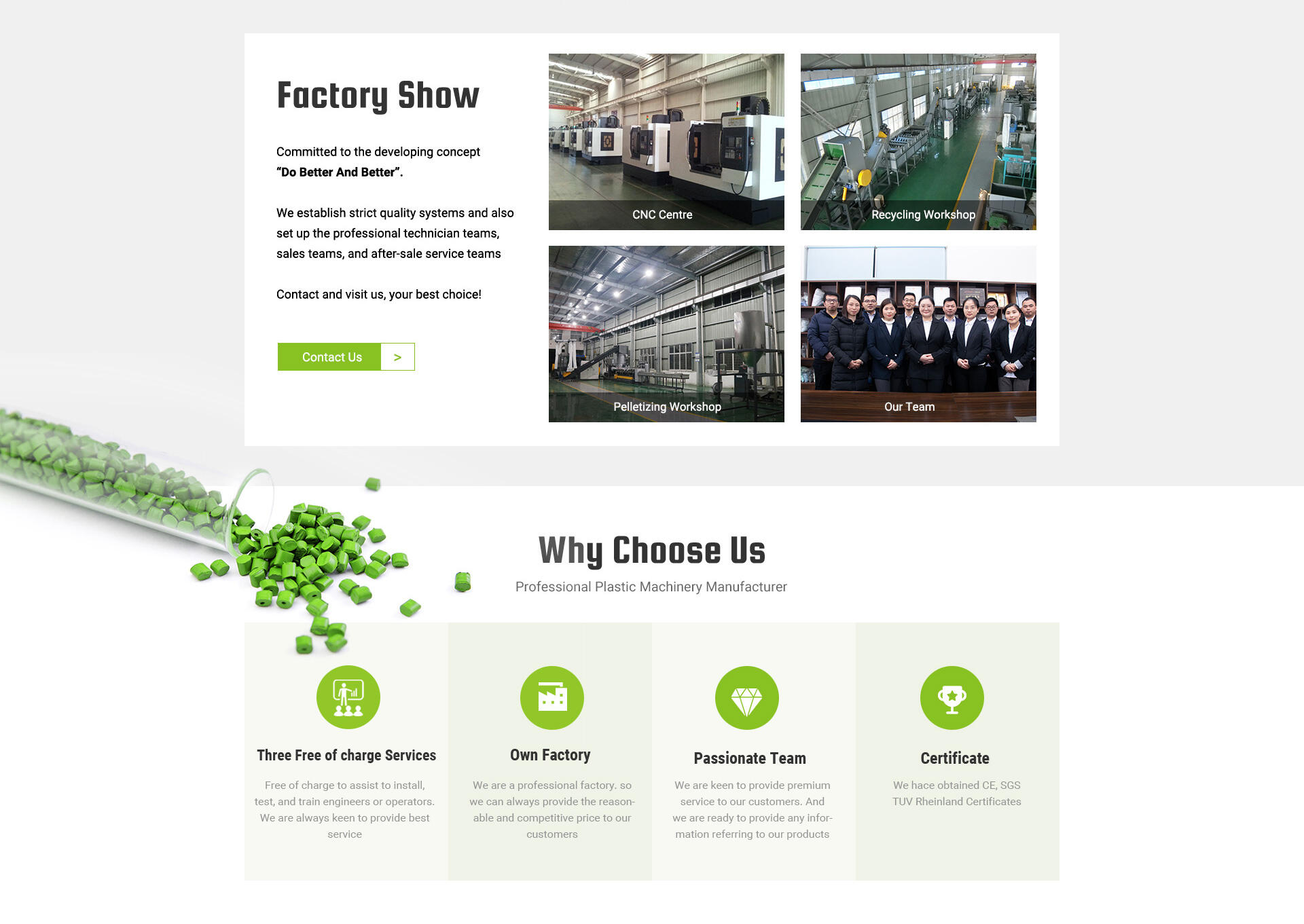

MOOGE

If you're looking for a waste plastic film washing line and crush machine that works quickly and efficiently, you may want to consider the MOOGE Fully Automatic PP PE Waste Plastic Film Washing Line and Crush Machine. This product is specifically designed to help businesses recycle and reuse plastic waste in a way that is both environmentally friendly and cost-effective.

Fully automatic, which means once it was set up that it requires small human intervention. Simply load your waste is plastic into machine, turn it on, and view as it quickly turns the waste into reusable plastic pieces.

Created to make use of several plastic materials, including PP and PE. Which means it can be utilized for a wide range of applications, from washing and plastic is crushing to recycling plastic bottles.

One of the important features of this machine is its capacity to perform a thorough and efficient process is washing. The washing line is equipped with multiple phases, including a hot washing stage and a washing phase is cool. This ensures that any dust, debris, or contaminants are removed from the synthetic prior to it being turned and crushed into reusable material.

Has a powerful crusher which can turn large pieces of plastic waste into small, consistent pieces as well as its efficient washing process. This helps it be easier to reuse synthetic and reduces the amount of waste that goes to landfills.

Manufactured with top-notch materials, which means it is built and durable to endure. It's also designed to become an easy task to operate and maintain, which helps to make sure that it will efficiently continue doing work for many years in the future.

If you're looking for a reliable and efficient way to recycle plastic waste, the MOOGE Fully Automatic PP PE Waste Plastic Film Washing Line and Crush Machine is an excellent choice. With its powerful washing and crushing capabilities, it can help businesses reduce their environmental footprint while also saving money on waste disposal costs.