ME-Series Waste Plastic Film/Bags Washing Recycling Machine/Line/Plant1. Me-series recycling machine widely for waste plastic pe / ldpe / lldpe / bopp / hdpe film, pp woven bag, pp jumbo bag, cement bags, jumbo bags, stretch film, packaging film etc. washing recycling

2. Waste dirty plastic material after crushing, friction washing, hot washing, dewatering, hot air drying process, it will turn to be clean flakes , the new plastic flakes will be pelletizing and injcetion new plastic.

3. The recycling line can be displayed "l" or "u" shape according to clients' workshop.

4. We can also customize the washing recycling line components according to client's material and product requirement.

Economic Type Recycling Line |

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

|

ME-300 |

|

|

|

|

|

|

|

|

|

|

ME-500 |

|

|

|

|

|

|

|

|

|

|

Advance Type Recycling Line: |

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

|

ME-300 |

|

|

|

|

|

|

|

|

|

|

ME-500 |

|

|

|

|

|

|

|

|

|

|

ME-1000 |

|

|

|

|

|

|

|

|

|

|

Plastic Crusher Machine

Crushing the waste film/bags with SKD-II blade, crusher machine top have water pipe inlet which was used to pre-washing the material.

Semi-Automatic Metal Detector

Check the metal before material into crusher machine, protect the crusher machine blade and screen

Plastic Shredder Machine

Baled Waste Film Bags Recycling Washing line, We can use heavy duty single shaft shredder machine. it can do 1000-2000 KG/H big capacity shredding in hour

High Speed Friction Washing Machine

By 900 RPM high speed rotor shaft , friction washing material , drain out dirty water at bottom, remover sand,soil etc. and loose material before going to float washing tank

Floating Washing Tank

Used to washing recycling the material, with top rollers automatic take out the film or bags flakes, dirty waste sinking down and drain out at bottom.

Plastic Dewatering Machine

1500 RPM high speed spin and remover dirty water for film or bags flakes, dirty water will drain out on the bottom,5~8% Moisture content

Hot Air Dryer

use 219mm big diameter stainless pipe and big power thermocouple drying the wet flakes,1~2% Moisutre content

Storage Silo

Big volume storage silo, made by SUS304

Electric Control Panel

Use SIEMENS PLC, ABB inverter, Schneider contactor etc.

ME-300 Russia Recycling Line

ME-500 Argentina Recycling line

ME-1000 Philippines Recycling line

ME-300 Mexico Recycling line

ME-500 India Recycling line

ME-1500 Domestic Recycling line

CHINAPLAS EXHIBITION

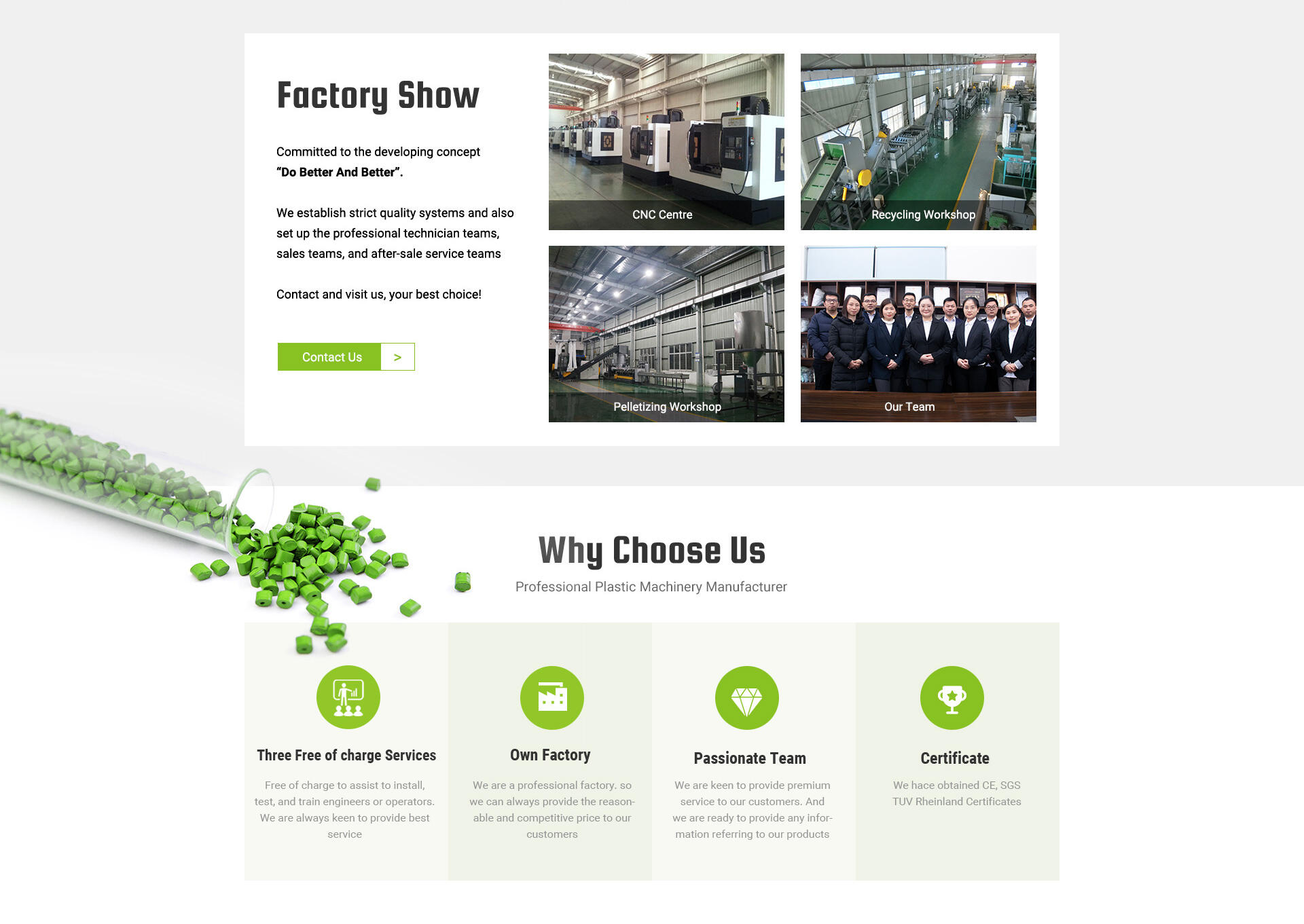

We attend the CHINAPLAS every year and take with our machine to test run at the booth. Besides, we also attend the plastic exhibition in other countries such as Mexico, Turkey, Egypt, Russia, Malaysia, etc. Sincerely welcome to our factory for visit and discuss technical issues.

Service Before Sale1. 24 hours online. Your inquiry will be quick reply by email.

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free.

If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you

request. We will tell you the tracking number after delivery.

Service After Sale1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

MOOGE

Looking for a high-quality and efficient plastic recycling machine? Look no further than MOOGE's 500-600 KG/H PE Film PP Jumbo Bags Crushing Friction Hot Washing Plastic Recycling Machine.

Specifically designed to help you efficiently recycle your waste is plastic in the shape of PE films, PP jumbo bags, or other kinds of plastic waste. With a crushing and friction washing procedure, this device is ready to effectively clean and process all of one's plastic waste, ensuring it is possible that you can recycle as much of it.

Capable of processing as much as 500-600 KG of plastic waste per hour, making it perfect for usage in large-scale applications which can be industrial. Additionally, it is highly efficient, with a minimal amount of energy necessary to run. Which means that you'll save cash on utility bills and reduce your environmental impact during the same time.

One associated with key features of this machine is its washing is hot process which gives a thorough neat and removes any contaminants from your synthetic waste. This ensures that the recycled plastic is of the product quality is highest and will be used in several applications.

Also exceedingly user-friendly in addition to its top-quality performance. It features simple and intuitive software that enables you to control all aspects associated with operation, through the crushing and washing process towards the output is final.

If you are looking for a high-quality plastic recycling machine that can handle large volumes of plastic waste, look no further than MOOGE's 500-600 KG/H PE Film PP Jumbo Bags Crushing Friction Hot Washing Plastic Recycling Machine. With its superior performance, efficiency, and ease of use, this machine is sure to become an essential part of your industrial operation.

×

×