×

×

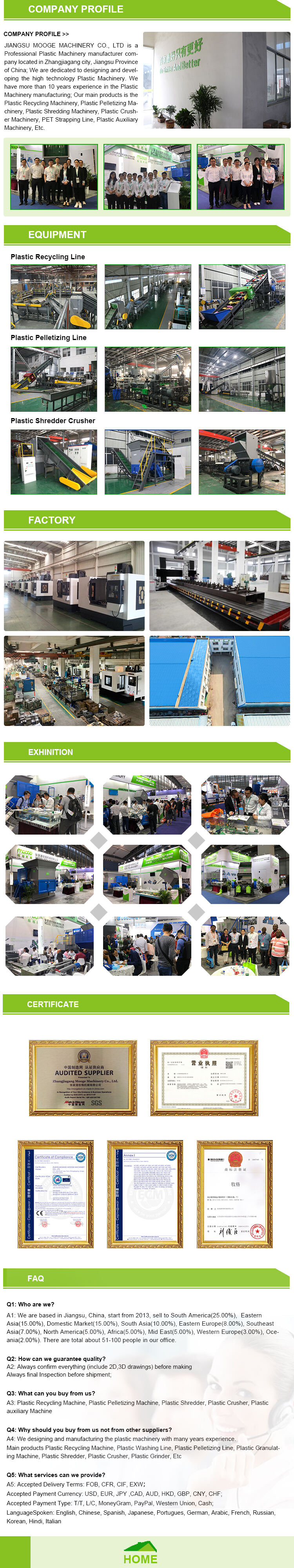

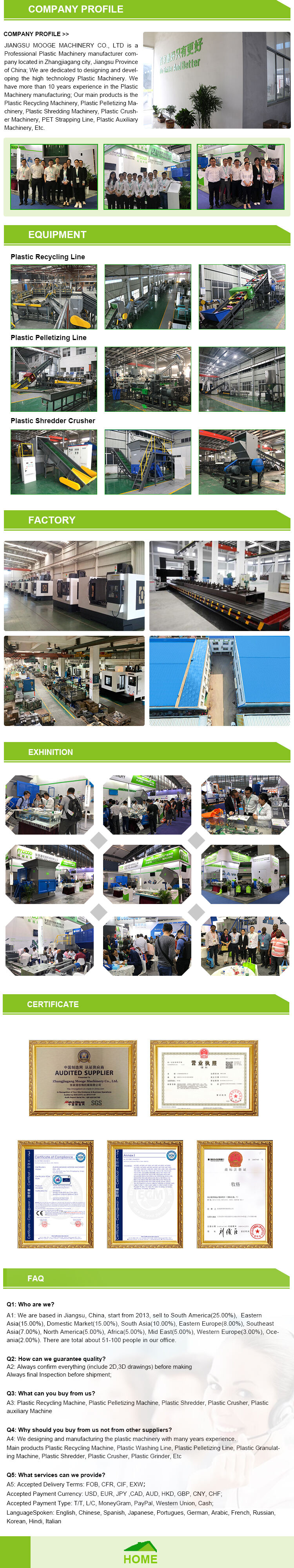

Launching the Waste Wasted Pet Drink Cola Coke Water Bottles Plastic Washing Production Machine Recycling Line Clean PET Bottle Flakes 10-12mm, the clear answer decrease ultimate waste and market a cleaner environment.

This product is made to effortlessly recycle and transform utilized animal containers into clean animal container flakes, prepared for reuse in producing products which are completely new. The MOOGE Recycling Line will be the solution ideal organizations that shoot for sustainability and eco-friendliness in their operations.

Making utilization of this revolutionary product is not difficult and easy, featuring its automated process that assures effectiveness optimum. The apparatus has technology state-of-the-art effortlessly eliminates contaminants through your pet containers, creating flakes which is often top-notch are suitable for different applications

The MOOGE Recycling Line is specifically developed to process types of animal containers, including those employed for normal water, cola, coke, along with other beverages. Featuring its setup versatile are made for assorted volumes of containers, making this suitable for any manufacturing line.

The gear is produced with durable and top-quality materials, ensuring performance lasting any functional problems. Its robust design minimizes upkeep requirements and provides efficiency optimal dependability.

In addition, the MOOGE Recycling Line features advanced security features that prioritize the security of the operators. The unit comes with protective covers and safety interlocks that prevent usage of areas that can easily be procedure dangerous.

This method is not only perfect for companies that want to get to lessen their effect ecological it really is additionally an opportunity very good individuals who aspire to capitalize on recycling being a way to obtain income. The MOOGE Recycling Line is actually a smart investment providing you with organizations with significant comes home in to the run very long.

Model |

Capacity |

Installed Power |

Water Supply |

Main power |

Area Required |

MT-500 |

500 kg/hr |

190 KW |

4-5 m3/hr |

4-6 Person |

60*5*5 m |

MT-1000 |

1000 kg/hr |

260 KW |

6-8 m3/hr |

8-10 Person |

80*8*5 m |

MT-2000 |

2000 kg/hr |

400 KW |

10-15 m3/hr |

10-12 Person |

80*8*5 m |

MT-3000 |

3000 kg/hr |

600 KW |

20-30 m3/hr |

12-16 Person |

100*8*10 m |

MT-4000 |

4000 kg/hr |

800 KW |

30-40 m3/hr |

15-20 Person |

135*10*10 m |

MT-5000 |

5000 kg/hr |

1000 KW |

40-50 m3/hr |

15-20 Person |

135*10*10 m |

Unit Energy Consumption |

||

Content |

Average energy consumption per ton of bottle |

|

Electricity |

70-90KW |

|

Water |

1-1.5T/hr |

|

Compressed air |

0.5-1m3 |

|

Steam (optional) |

250-400KG |

|

Detergent (optional) |

4-8KG |

|

Bottle Flakes Quality Reference |

||

Technical Parameter |

Specifications |

|

Flakes size |

12-14mm |

|

Moisture Content |

<1%<> |

|

PVC Content |

Less than 100 ppm |

|

PH |

7.5 +/- 0.5 |

|

Intrinsic Viscosity |

> 0.70 |

|

Non-PET |

Less than 100 ppm |

|

Color PET |

Less than 150 ppm |

|

Bulk density |

250-400 kg/m³ |

|

Suitable to be used for |

Polyester/ PET strapping/ Polyester Fiber/ PSF/ PET Sheet |

|