×

×

MOOGE

Plastic Waste PET Bottles Washing Line Machinery will be the solution is certainly ultimate any business trying to effortlessly and effortlessly procedure waste that synthetic. This state-of-the-art machinery is designed to handle a lot of different PET containers, ensuring on a clean and end product which is recycled.

The MOOGE Plastic Waste PET Bottles Washing Line Machinery is designed with top-notch, durable materials to make sure use this is certainly durable. The machinery can be a task is easy operate, rendering it and choice is ideal any business.

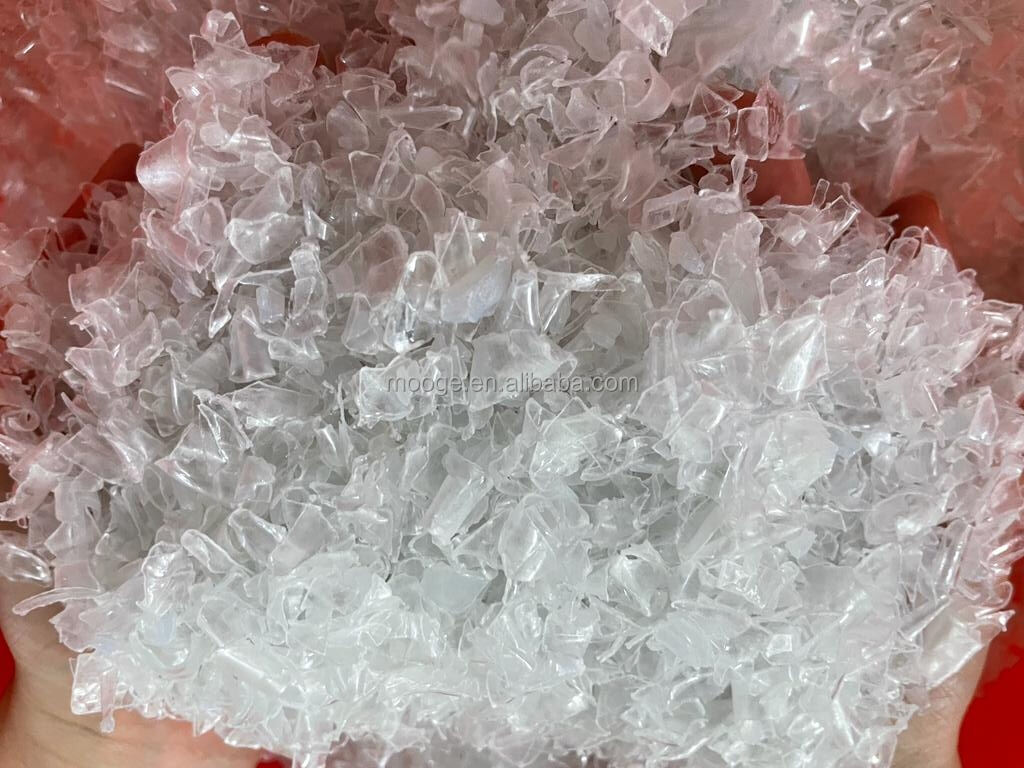

Perhaps one of the most shows are significant this machinery could it be is really specifically designed to tackle waste materials that is plastic. This means it really is noteworthy in getting rid of any impurities from PET containers, such as dust, labels, and caps. The machinery uses a series of washing and rinsing processes to make sure an end is certainly thoroughly cleaned, that will be critical for organizations which are devoted to sustainable practices.

Another feature that is essential of MOOGE Plastic Waste PET Bottles Washing Line Machinery is its effectiveness. This machine features an ability is certainly high can process large volumes of materials at any moment. In addition, it is designed with specialized equipment that speeds up the strategy, reducing the amount that total of necessary to finish a task. This particular feature is vital for businesses which have tight due dates and also to process materials quickly.

The MOOGE Plastic Waste PET Bottles Washing Line Machinery can be fashioned with also safety at heart. a quantity of security features, such as for instance emergency stop buttons and interlocks, make sure that the apparatus can very be turn off quickly and simply in case of a major accident. It is a consideration is certainly very important companies that prioritize the security of the workers.

Finally, the MOOGE Plastic Waste PET Bottles Washing Line Machinery is made with most of the environment in your thoughts. Making usage of recycled materials in production and waste is efficient systems make sure that this machinery includes a minimal effect on the environmental surroundings. This will be an element is key will appeal to companies looking to reduce their carbon impact which makes a positive effect on our planet.

Recycling Model |

Capacity |

Installed Power |

Water Supply |

Manpower |

MT-500 |

500 kg/hr |

190 KW |

4-5 m3/hr |

4-6 Person |

MT-1000 |

1000 kg/hr |

260 KW |

5-7 m3/hr |

8-10 Person |

MT-2000 |

2000 kg/hr |

400 KW |

10-15 m3/hr |

10-12 Person |

MT-3000 |

3000 kg/hr |

600 KW |

20-30 m3/hr |

12-16 Person |

MT-4000 |

4000 kg/hr |

800 KW |

30-40 m3/hr |

15-20 Person |

MT-5000 |

5000 kg/hr |

1000 KW |

40-50 m3/hr |

15-20 Person |

De-Baler Machine in Recycing Line:

De-baling baled Pet bottle, With 4 roller cylinder to feeding the bottles equally to next process

Label Remover Machine in Recycing Line:

High Speed Rotor Removing, Separator label for bottle before into crusher machine and recycling hot washing tank. Label Remove Effective > 92% (According To Different Bottle)

Detachable Blade, Easy for worker maintenance

Plastic Crusher Machine in Recycing Line:

With water, high speed crushing grinder bottle in recycling line use motor open crusher machine chamber, high efficiency change blade use DC-53/D-2 Blade, Better HRC and Strong

Hot Washing Tank in Recycing Line:

With hot water washing dirty flakes, by caustic soda chemical agential, remover oil, glue etc. heating method: by 60KW* 2 electric or steam boiler system. Double layer insulation, save power

High Speed Dewatering Machine in Recycing Line:

1500 RPM High speed dewatering pet flakes, remover pet fine, dirty soil etc. inner welding water pipe, washing screen

Cold Water Float Washing Tank in Recycing Line:

By washing tank washing, separator pet bottle flakes, pe pp caps etc. in recycling line

Zia Zag Air Classifier in Recycing Line:

The residual tags are separated by the principle of gravity by fan blower control valve

Automatic Color Sorting Machine for PET Bottle Flakes Recycling Line

Automatic sorting pet flakes, remover green, brown etc. flakes

Service before sale recycling machine

1. 24 hours online .Your inquiry will be quick reply by email. Also can go through all questions with you by any online chatting tools (WeChat, WhatsApp, Skype, Viber, QQ, and Trade Manager

2. Professionally and patiently introduction, details pictures and working video to show machine

Service on sale:

1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport .Will tell you the shipping time and arrival time. Finally, send all original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, FedEx, etc.) or by air to your airport, or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service after sale recycling machine

1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory