×

×

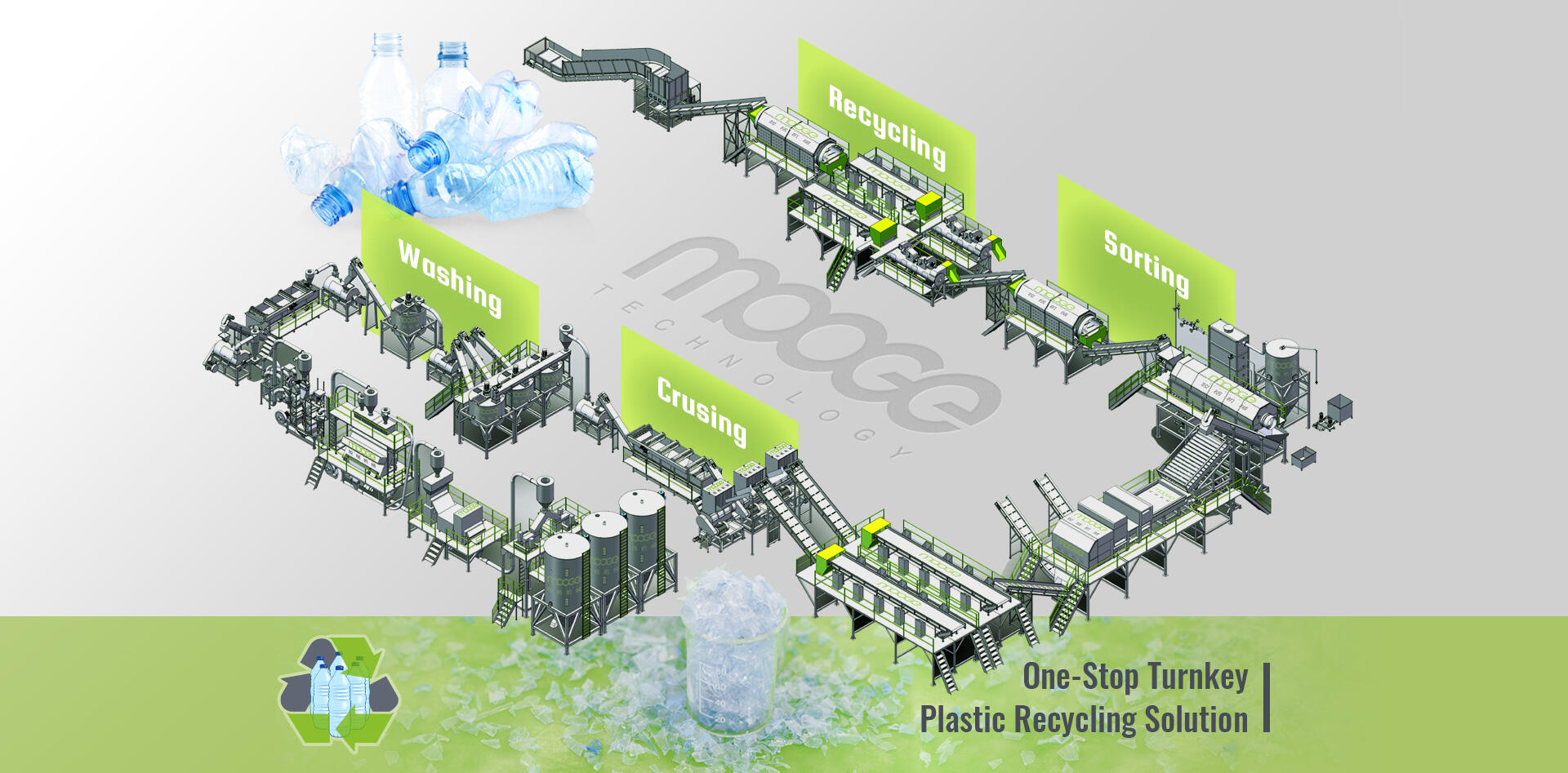

The Waste Plastic PET Bottle Scrap Crushing Washing Drying Recycling Line from MOOGE is just a convinced that is ahead that will help you recycle waste synthetic containers in an easy and way that is efficient.

The method that is whole of bottles which can be plastic a few actions, as well as this recycling line was created to simplify the strategy by combining crushing, washing, drying, and recycling straight into a task this is actually solitary. With this particular item that is specific is particular you can turn your waste synthetic containers into helpful materials which are generally reused in many ways.

Made materials which are using are top-quality are durable and developed to withstand the recycling procedure that is rigorous. The line just isn't tough to create and exercise usage of, with user-friendly settings that create the technique effective and effective. By using this line, it truly is very easy to recycle any type of animal container, including water containers, soft drink containers, and juice containers.

The action this is actually first the recycling procedure is crushing the containers. Includes a crusher that is high-speed can effectively crush your waste synthetic containers into small pieces. The containers have decided by this task which is often washing that is synthetic.

Next could be the containers are increasingly being washed by procedure. Features a washing this is really top-notch that uses water that is beneficial to scrub the containers completely. This task really helps to make certain that dirt that is many, dust, and contaminants are eliminated through the containers.

After washing, the containers are dried out having a functional system that is exclusive is drying. Carries a technique this is uses being undoubtedly drying that is hot dry the containers quickly and effectively. All dampness is eliminated by this task through the containers, making them ready for recycling.

Finally, the synthetic this is really recycled may be employed for various purposes, including synthetic that is producing is brand new, building materials, as well as garments. Using this, you will reduce your carbon effect and may play a role in cleaner and healthiest surroundings.

Make fully sure you get your Waste Plastic PET Bottle Scrap Crushing Washing Drying Recycling Line from MOOGE and begins today that is recycling.

Model |

Capacity |

Installed Power |

Steam Use |

Water Supply |

Area Requied |

MT-500 |

500 kg/hr |

185 KW |

Optional Choose |

4-5 m3/hr |

55*3.5*4.5 m |

MT-1000 |

1000 kg/hr |

315 KW |

Optional Choose |

5-6 m3/hr |

62*5*4.5 m |

MT-2000 |

2000 kg/hr |

450 KW |

Suggest Use |

10-15 m3/hr |

80*6*5 m |

MT-3000 |

3000 kg/hr |

600 KW |

80000 Kcal |

20-30 m3/hr |

100*8*5.5 m |

MT-4000 |

4000 kg/hr |

800 KW |

100000 Kcal |

30-40 m3/hr |

135*8*6.5 m |

MT-5000 |

5000 kg/hr |

1000 KW |

120000 Kcal |

40-50 m3/hr |

135*8*6.5 m |