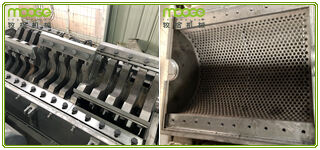

>Bearing house is installed outside of the chamber so no dirty goes inside which prolong the lifespan

> Upside hopper is covered by shelter so no flakes popped out.

×

×

Brand: MOOGE

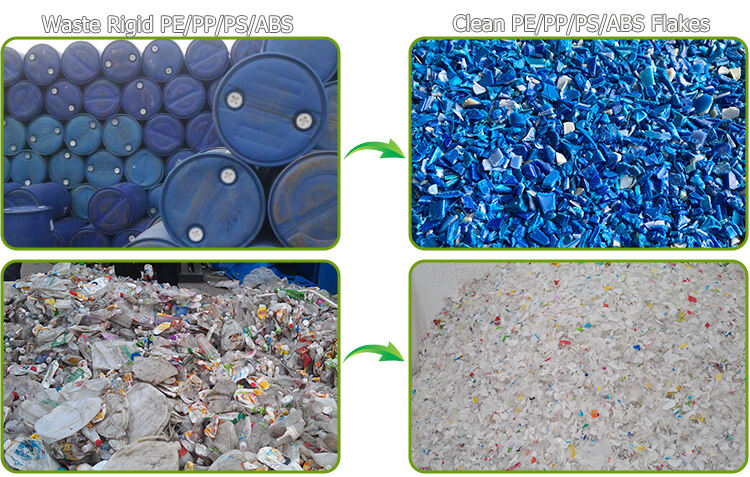

MOOGE’s Waste Rigid Hdpe Milk Bottle Recycling Pp Plastic Washing Plant is an innovative product that offers an effective and environmentally friendly solutions to the challenge of plastic waste disposal. The plant is designed to efficiently cleans and recycle HDPE milk bottles, PP plastics and other waste rigid plastic materials, converting them into useful and sustainable resources.

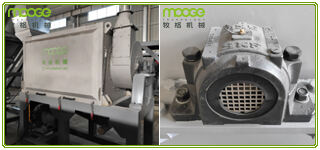

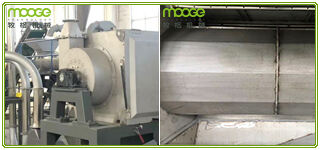

Made from high-quality materials that guarantee its durability and longevity. The plant comprises several key components including a shredder, crusher, washer, dewatering device, and system that is drying. The shredder is used to break down the plastic that is rigid tiny pieces, while the crusher grinds the plastic into smaller particles that will be fed into the automatic washer. The washing device contains several rotating and devices that are spraying effectively remove dirt, oil, and other impurities.

The equipment that is dewatering to remove any water content, while the drying system ensures that the plastic is completely dry before it is passed on to another location stage of the recycling process. Designed to handle large volumes of plastic waste, which makes it a solution that is perfect municipalities, recycling facilities, and manufacturing flowers.

Apart from its efficiency, additionally eco-friendly considering that the amount is reduced by it of plastic waste that ends up in landfills and the oceans. The employment of recycled plastic in the production procedure also helps to save resources that are natural reduce carbon emissions.

Simple and user-friendly to steadfastly keep up. It's built with safety features that ensure the safety of the operators during operation. The plant comes having a manual that is detailed provides clear instructions on how best to operate and maintain it, which makes it easy for both novice and experienced operators to used.

The MOOGE Waste Rigid HDPE Milk Bottle Recycling PP Plastic Washing Plant is an excellent investment for anyone who is looking for an efficient and eco-friendly solutions to plastic waste disposal. It is a product that guarantees value for money and is designed to offers a long lifespan and superior performance. You can now contribute to creating a greener and more sustainable world.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5m |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5m |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5m |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5m |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5m |

Item |

Specification |

Raw Material |

Waste Rigid Plastic PE bottle, HDPE barrel, PP bucket, PS Box, ABS shell, etc |

Finished Product |

Clean dry plastic flakes (size can be recycled as buyer request) |

Main Machine List |

Belt Conveyor, Shredder, Crusher, Cold Washing Tank, High Speed Friction Washer, Hot Washing Tank, Centrifugal Dryer, Hot Air Pipeline, Packing Silo |

Machine Material |

Machine frame is made by carbon steel, the machine washing part is made by SUS 304 |

Main Components |

NSK/SKF bearing, TTO oil sealing, Guomao reducer,etc. |

Electric Components |

ABB/Delta inverter, Omron temperature meter, Schneider contactor, Chint switch, Siemens made in China motor, etc. |

Warranty Period |

One Year from the Machine Operation within 18 Months from the B/L Date |

Turnkey After Service |

Technical Support including the machine layout, electric diagram, working manual, engineer available to buyer's factory overseas for helping installation, commissioning, training workers, etc. consumable parts provided; 24-hours online after sale service; |