×

×

The Waste Plastic PP PE HDPE Bottle Hollow Container Recycling Machine Plant may be the solution ideal any company or community trying to reduce their effect on the surroundings while additionally producing top-quality materials. This plant was made to just take waste synthetic containers of all of the sizes and turn them into helpful and products which are valuable.

This recycling device plant is created specifically to recycle PP, PE, and HDPE synthetic materials. These materials could be discovered in a number of products and services such as for instance packaging, containers, and containers. By recycling these materials, companies and communities can lessen their waste and minimize their ecological effect.

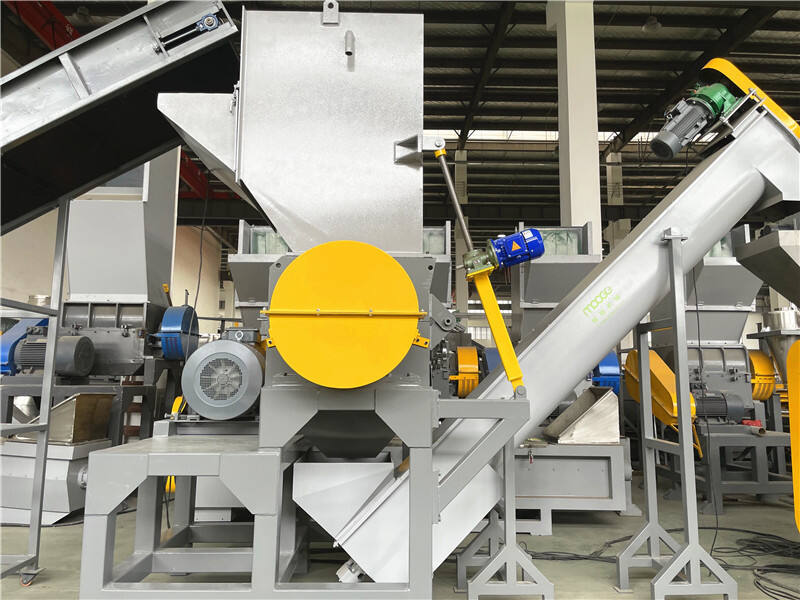

The Waste Plastic PP PE HDPE Bottle Hollow Container Recycling Machine Plant is truly a system very efficient integrates shredding, crushing, and procedures that are washing. This gear advanced process huge amounts of synthetic waste in a quantity brief of and creates high-quality materials which you are able to use within lots of applications.

The plant comes with high level technology to ensure the services that are finished products are regarding the quality greatest. The shredding process breaks straight down the plastic containers into tiny pieces, rendering it easier to undertake to the stage next. The crushing procedure then decreases how big the synthetic pieces, as well as the washing procedure cleans them completely.

Utilising the Waste Plastic PP PE HDPE Bottle Hollow Container Recycling Machine Plant, companies and communities can cause top-notch synthetic recycled that can be used in a large amount various applications. The synthetic recycled allows you to produce brand containers that are new packaging, as well as other items. This decreases the requirement for virgin plastic materials and assists organizations and communities minimize their ecological effect.

This recycling device plant can be very easy also to operate and requirements upkeep minimal. Its created to therefore be user-friendly the settings are actually easy to make use of. This may allow it to be an solution perfect organizations and communities of all of the sizes.

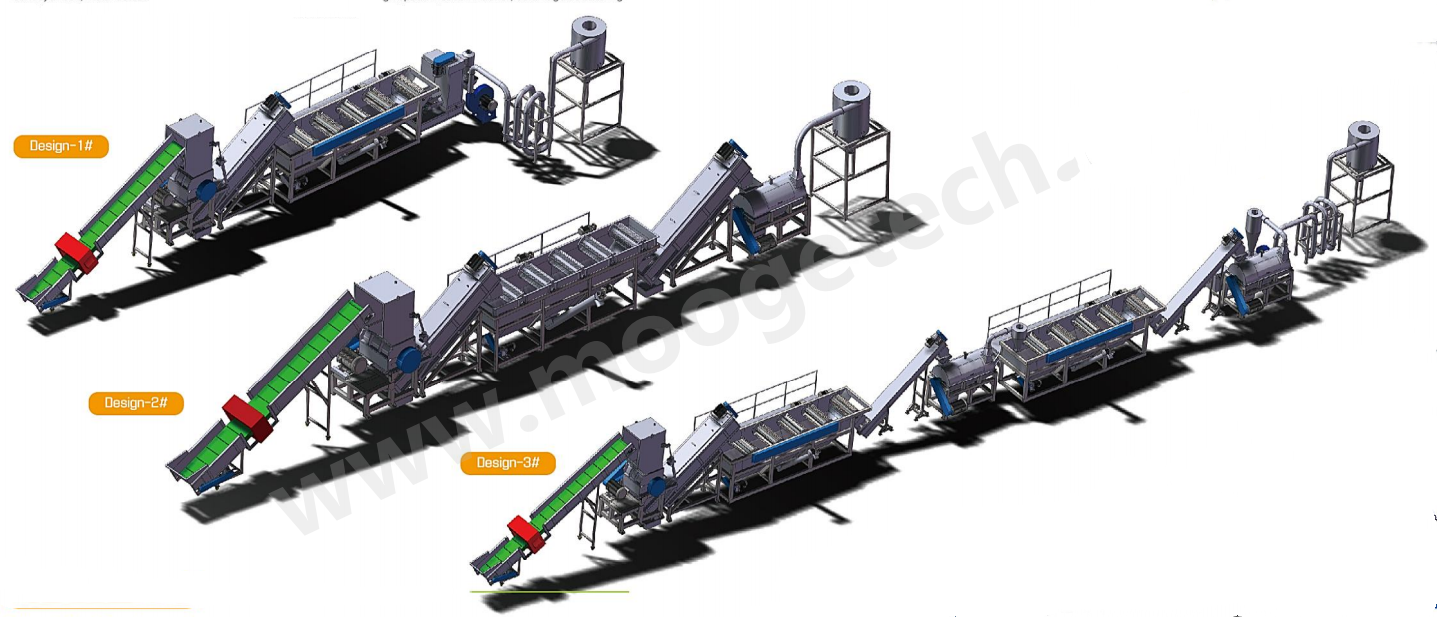

Model |

Capacity |

Installed Power |

Water Supply |

Area Required :m |

MEB-300 |

300kg/hr |

100KW |

4-5m³/hr |

20*4.5*5 |

MEB-500 |

500kg/hr |

115KW |

5-6m³/hr |

20*4.5*5 |

MEB-1000 |

1000kg/hr |

125KW |

7-8m³/hr |

23*5*5 |

MEB-1500 |

1500kg/hr |

180KW |

8-10m³/hr |

25*5*5 |

MEB-2000 |

2000kg/hr |

225KW |

10-15m³/hr |

28*5*5 |

Model |

Capacity |

Installed Power |

Water Supply |

Area Required:m |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5 |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5 |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5 |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5 |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5 |