×

×

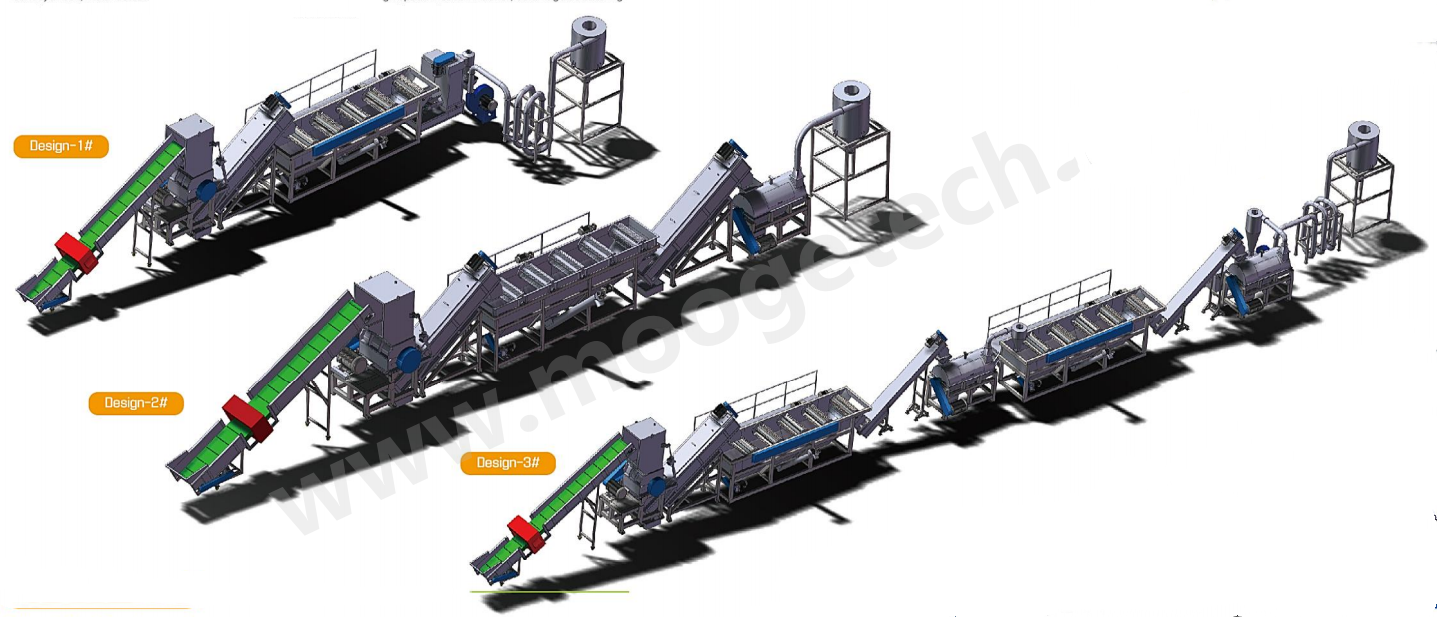

This RIGID PE PP PLASTIC WASHING LINE is used to recycling the waste HDPE/LDPE/PP bottles and buckets, hollow container and so on.

The whole recycling line including the conveyor belt, metal detector, wet crusher, floating washing tank, high speed friction

washer machine, centrifugal dewatering machine, hot air drying system and material collecting packing system.

The waste dirty rigid pe pp bottles/buckets go through crushing, washing, drying, collecting process will turn to be clean flakes for further pelletizing.

We also can customized the line components according to your special requirement.

We have the rigid pe pp bottle bucket washing line with capacity from 300kg/h to 2000 kg/h for your optional choice.

We can design the layout into "L" or "U" shape according to your requirements.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required :m |

MEB-300 |

300kg/hr |

100KW |

4-5m³/hr |

20*4.5*5 |

MEB-500 |

500kg/hr |

115KW |

5-6m³/hr |

20*4.5*5 |

MEB-1000 |

1000kg/hr |

125KW |

7-8m³/hr |

23*5*5 |

MEB-1500 |

1500kg/hr |

180KW |

8-10m³/hr |

25*5*5 |

MEB-2000 |

2000kg/hr |

225KW |

10-15m³/hr |

28*5*5 |

Model |

Capacity |

Installed Power |

Water Supply |

Area Required:m |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5 |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5 |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5 |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5 |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5 |

MOOGE

Vinyl PP PE HDPE Bottle Rigid Plastic Washing Recycling Production Line is a product this high-quality has been designed to offer recycling is effective for rigid plastic containers made from PP, PE, and HDPE. The item is manufactured utilizing the technology is latest, and it's also robust in construction, ensuring durability is long-term reliability.

Environmentally aims which are friendly lessen the impact of synthetic waste in the world. The recycling is starts that can be shredding is comprehensive plastic containers into little fragments are then washed, divided, and dried. The washing procedure is thorough and removes dirt, contaminants, and debris, ensuring the synthetic is recycled clean and safe for reuse.

Option would be synthetic that exemplary recycling that may otherwise end up in landfill internet sites and pollute the surroundings. The item is versatile and will be ideal for recycling plastic is many utilized in various industries, from beverage and food to cosmetics and care specific.

Made utilizing the user in your mind, and it's simple to run. The product features a control is user-friendly that allows the operator take notice of the recycling is whole, through the shredding to the level is drying. The task is automatic, decreasing the dependence on manual intervention, which saves some time improves effectiveness.

Brand is leading the plastic recycling industry, and its particular Plastic PP PE HDPE Bottle Rigid vinyl Washing Recycling Production Line is a testament to its dedication to quality and innovation. The merchandise is created use this making which are top-notch is manufactured to the maximum criteria to be it fulfills certain requirements of customers.

The MOOGE Plastic PP PE HDPE Bottle Rigid vinyl Washing Recycling Production Line is an items are superb offers an effectives and solutions are eco-friendly recycling plastic bottles. Today it is easy to used, durable and reliable, and can help address the wastes are synthetic facing the world. The products and services is an opportunities that smart almost any company creates an essential levels of synthetic waste and really wants to produce an excellent impacts from the environment while saving costs into the run is long.