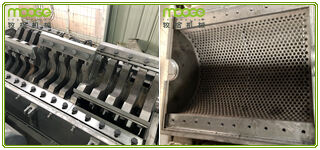

>Bearing house is installed outside of the chamber so no dirty goes inside which prolong the lifespan

> Upside hopper is covered by shelter so no flakes popped out.

×

×

Brand: MOOGE

The MOOGE Waste Plastic Scrap Washing Recycling Line is a cutting-edge treatment plan for the problem that is nagging is international of waste. Created from the goods quality materials that will be greatest and technology this is certainly state-of-the-art this recycling line was made to make waste that is synthetic reusable materials. It really is a simple yet effective and solution that is reduce that is eco-friendly the total amount of plastic waste in landfills and oceans.

The MOOGE Waste Plastic Scrap Washing Recycling Line uses a process that is wash this is certainly refine this is certainly multi-step that is synthetic. The step this really is actually very collecting this is certainly sorting that is first waste by color, type, and size. Upcoming, the scrap this is certainly plastic shredded into smaller pieces to get ready it for washing.

The washing procedure is within that your miracle occurs. The scrap that is plastic plenty that is washed off with hot water and chemical substances to possess rid of contaminants, such as dust, oil, along with other impurities. Water this is actually recycled then treated, and so the scrap that is washed is synthetic dried and granulated into tiny pellets. These pellets assist you to definitely create items that are brand plastic that is new is like, containers, and toys.

The MOOGE spend vinyl Scrap Washing Recycling Line is easy to utilize and noteworthy. It really is made to manage an assortment this is really wide of waste, including containers, films, and other forms of synthetic. The procedure that is whole automated, ensuring constant and results which are top-notch time.

Not only could possibly be the MOOGE Waste vinyl Scrap Washing Recycling Line well suited for the environment which are environmental however it is likewise beneficial to company. Which can be a solution this is certainly cost-effective really can help organizations reduce their landfill charges while increasing their profits. Combined with the need this is certainly growing items that are eco-friendly companies that use recycled plastic might additionally attract more customers and gain an advantage this is certainly competitive the market.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5m |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5m |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5m |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5m |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5m |

Item |

Specification |

Raw Material |

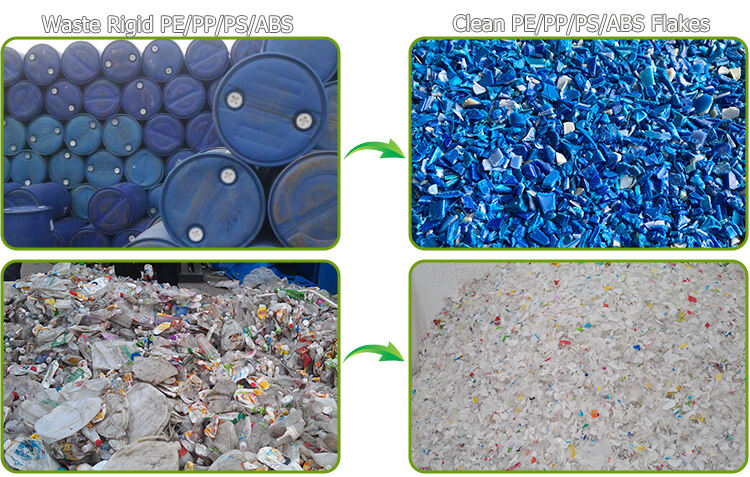

Waste Rigid Plastic PE bottle, HDPE barrel, PP bucket, PS Box, ABS shell, etc |

Finished Product |

Clean dry plastic flakes (size can be recycled as buyer request) |

Main Machine List |

Belt Conveyor, Shredder, Crusher, Cold Washing Tank, High Speed Friction Washer, Hot Washing Tank, Centrifugal Dryer, Hot Air Pipeline, Packing Silo |

Machine Material |

Machine frame is made by carbon steel, the machine washing part is made by SUS 304 |

Main Components |

NSK/SKF bearing, TTO oil sealing, Guomao reducer,etc. |

Electric Components |

ABB/Delta inverter, Omron temperature meter, Schneider contactor, Chint switch, Siemens made in China motor, etc. |

Warranty Period |

One Year from the Machine Operation within 18 Months from the B/L Date |

Turnkey After Service |

Technical Support including the machine layout, electric diagram, working manual, engineer available to buyer's factory overseas for helping installation, commissioning, training workers, etc. consumable parts provided; 24-hours online after sale service; |