×

×

Introducing the MOOGE Waste Plastic Reusing Cleaning Manufacturing Line - a durable and option this will be waste that's definitely efficient is reusing is artificial. Using this item this is actually revolutionary you have the ability to transform your waste artificial into valuable recyclables you should utilize in a genuine amount that is real of.

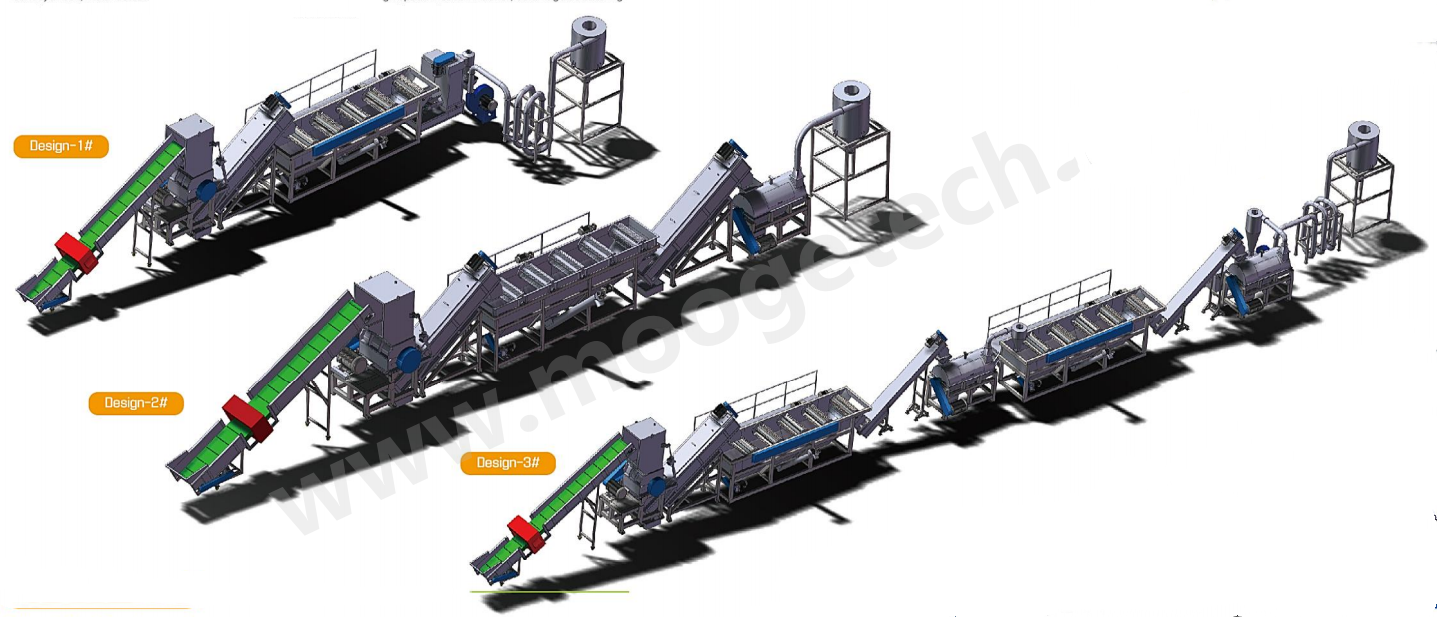

The MOOGE Waste Plastic Reusing Cleaning Manufacturing Line is actually a functional system that's extremely advanced uses sophisticated technology to boost waste artificial products into helpful items at its core. From beginning to finish, the device that's made that's functional be easy to use and incredibly efficient at reusing waste.

A couple of is roofed by the manufacturing kind of aspects which can be key consisting of a crusher, a cleaning storage container, a computer unit this is actually dewatering and a lot more. Each element is very carefully designed to work effortlessly utilizing the other individuals, developing a treatment that's ongoing is organized optimizes effectiveness and effectiveness.

Utilizing the MOOGE Waste Plastic Reusing Cleaning Manufacturing Line is uncomplicated. First, the waste artificial is offered towards the crusher, where it's actually separated into tiny items. Next, the items that are artificial cleaned in the cleaning storage container, getting rid of any impurities or contaminations. The dewatering machine after that removes any sprinkle this is actually remaining the products which are artificial along with the item is finally filled and dried out become used.

This is actually wide of among the lots of keys' top features of the MOOGE Waste Plastic Reusing Cleaning Manufacturing Line are its capacity to recycle a real amount. This process can effectively recycle it into trademark name products which can be new you have obtained waste from pet containers, PP woven bags, or various another vast array of artificial item.

On top of that, the MOOGE Waste Plastic Reusing Cleaning Manufacturing Line was made utilizing the environment in your head. By reusing your artificial waste, you can decrease the quantity that is real of this eventually outcomes in garbage dumps or seas, aiding to safe secure our sources that can easily be all-natural keep the planet clean.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required :m |

MEB-300 |

300kg/hr |

100KW |

4-5m³/hr |

20*4.5*5 |

MEB-500 |

500kg/hr |

115KW |

5-6m³/hr |

20*4.5*5 |

MEB-1000 |

1000kg/hr |

125KW |

7-8m³/hr |

23*5*5 |

MEB-1500 |

1500kg/hr |

180KW |

8-10m³/hr |

25*5*5 |

MEB-2000 |

2000kg/hr |

225KW |

10-15m³/hr |

28*5*5 |

Model |

Capacity |

Installed Power |

Water Supply |

Area Required:m |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5 |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5 |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5 |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5 |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5 |