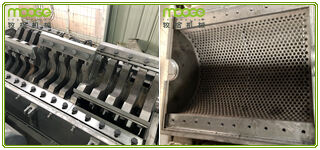

>Bearing house is installed outside of the chamber so no dirty goes inside which prolong the lifespan

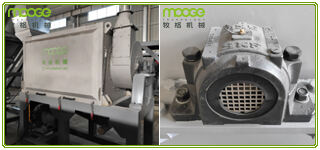

> Upside hopper is covered by shelter so no flakes popped out.

×

×

MOOGE

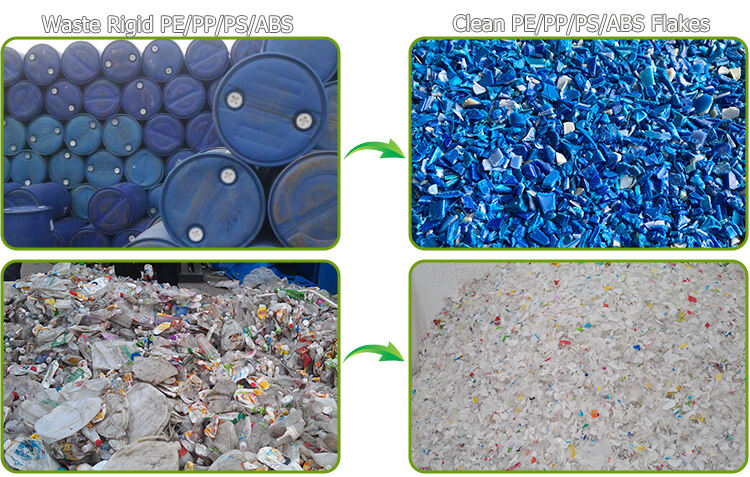

Waste Bottle Flakes Plastic Recycling Line is a machine is certainly important companies are trying to show their waste into revenue. With this particular line, companies can easily recycle and transform waste this is certainly synthetic reusable materials to reduce their carbon footprint. This machine is ideal for companies that use plastic containers and want to recycle them efficiently.

The MOOGE Waste Bottle Flakes Plastic Recycling Line comprises of various shredders, crushers, washers, and machines which is often drying. Each machine is designed to manage different phases of this recycling process to create top-quality synthetic that is recycled. The action that is first the recycling process is shredding, where in actuality the plastic containers are divided into tiny pieces. Then, the crusher crushes the synthetic that is shredded also smaller pieces.

The step is next the procedure washing the synthetic flakes. The washing machine eliminates any impurities or contaminants through the plastic flakes. Additionally, the washing machine uses water that is hot detergents that really help break up any remaining dust and grease concerning the plastic flakes. The machine is drying any dampness through the synthetic flakes, making them prepared to be used after the washing procedure.

MOOGE's Waste Bottle Flakes Plastic Recycling Line is simple to get results, along with design is user-friendly, enabling companies to recycle waste efficiently and efficiently. The line that is entire intended to lessen the number of power used in the recycling process, meaning that it features an energy usage rate is low. Furthermore, this machine has an output is certainly high, rendering it a great investment for companies that are looking for to grow their recycling capabilities.

One of several advantages of MOOGE's Waste Bottle Flakes Plastic Recycling Line is so it produces high-quality plastic is recycled that can be used in many different industries. The materials that are plastic are cost-effective, as well as the production procedure makes utilization of fewer resources, that makes it and solution is eco-friendly.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5m |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5m |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5m |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5m |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5m |

Item |

Specification |

Raw Material |

Waste Rigid Plastic PE bottle, HDPE barrel, PP bucket, PS Box, ABS shell, etc. |

Finished Product |

Clean dry plastic flakes (size can be recycled as buyer request) |

Main Machine List |

Belt Conveyor, Shredder, Crusher, Cold Washing Tank, High Speed Friction Washer, Hot Washing Tank, Centrifugal Dryer, Hot Air Pipeline, Packing Silo |

Machine Material |

Machine frame is made by carbon steel, the machine washing part is made by SUS 304 |

Main Components |

NSK/SKF bearing, TTO oil sealing, Guomao reducer, etc. |

Electric Components |

ABB/Delta inverter, Omron temperature meter, Schneider contactor, Chint switch, Siemens made in China motor, etc. |

Warranty Period |

One Year from the Machine Operation within 18 Months from the B/L Date |

Turnkey After Service |

Technical Support including the machine layout, electric diagram, working manual, engineer available to buyer's factory overseas for helping installation, commissioning, training workers, etc. consumable parts provided; 24-hours online after sale service; |

In order to match your requirement and provide you a proper offer, please advise:

• What material do you want to recycle? PE film/PP bag? HDPE/PP bottle? PET bottles? Or other plastic?

• What capacity (kg/h) do you want? Such as 500kg/hr or 1000kg/hr?

• What is the final size (mm) of flakes you want?

• Other special requirements about the Hot Sale Waste Pe Plastic Bottle Pp Recycling Washing Machine if you have?