×

×

Machine Model |

RSS |

Brand |

MOOGE |

Applicable Material |

LDPE, LLDPE, HDPE, PP, BOPP, CPP, EPS, PS, PPS, ABS, PA, PLA |

Capacity |

200-1200KG/H |

Screw Diameter |

80-180MM |

Screw Design |

Single Screw |

L/D Ratio |

33-44/1 |

Screw rpm |

90-180 |

Screw Material |

38CrMoAl |

Gearbox Brand/type |

Guomao Brand/ High Torque Vertical |

Motor Brand |

SIEMENS or Chinese Brand |

Degassing Zone |

2 |

Pelletizer type |

Water ring pelletizer |

Total Power |

150-650KW |

Delivery Time |

60 days |

Guarantee |

12 months |

Certificate |

CE |

Technology Parameter |

Technology Parameter |

|||||||||||

Type |

SJ-100 |

SJ-120 |

SJ-150 |

SJ-180 |

SJ-200 |

|||||||

Capacity (kg/h) |

200-300 |

300-400 |

400-500 |

600-800 |

800-1000 |

|||||||

Energy consumption (kWh/kg) |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

|||||||

Exturder

|

Screw Diameter (mm) |

Φ100 |

Φ120 |

Φ150 |

Φ180 |

Φ200 |

||||||

L/D |

33-44/1 |

33-44/1 |

33-44/1 |

33-44/1 |

33-44/1 |

|||||||

Motor power (kW) |

75 |

90 |

110 |

160 |

200 |

|||||||

Filter

(options)

|

Two position plate type |

● |

● |

● |

● |

● |

||||||

Two position piston type |

○ |

○ |

○ |

○ |

○ |

|||||||

Back flush piston type |

○ |

○ |

○ |

○ |

○ |

|||||||

Automatic self-cleaning type |

○ |

○ |

○ |

○ |

○ |

|||||||

2nd Extruder

(optional)

|

Screw Diameter (mm) |

Φ100 |

Φ120 |

Φ150 |

Φ180 |

Φ200 |

||||||

L/D |

8-12/1 |

8-12/1 |

8-12/1 |

8-12/1 |

8-12/1 |

|||||||

Motor power (kW) |

30 |

45 |

55 |

75 |

90 |

|||||||

Downstream (options)

|

Water ring pelletizer |

● |

● |

● |

● |

● |

||||||

Strand pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

Automatic strand pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

Underwater pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

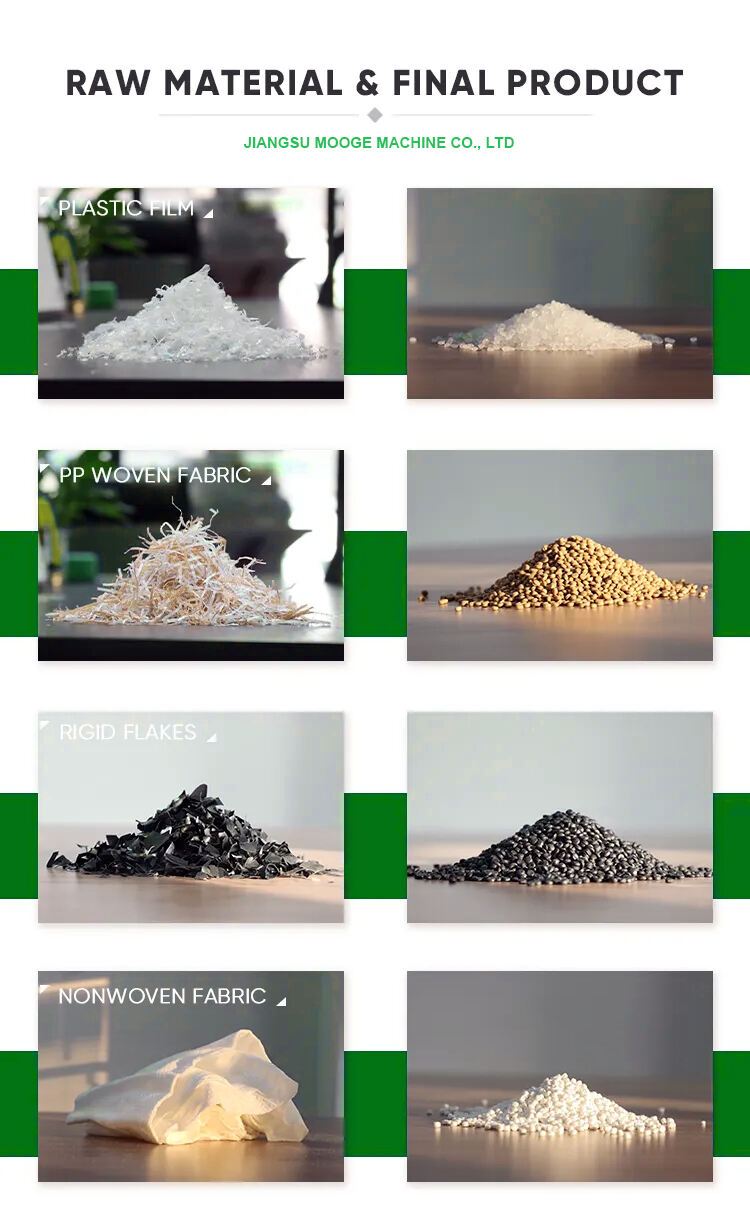

MOOGE

Recycled PP PE Plastic Pelletizing Recycling Ldpe movie Plastic Granulator device, the innovative and solution is eco-friendly plastic recycling. The item is made to recycle waste is plastic including LDPE movie, into high-quality plastic pellets which is used for lots of applications.

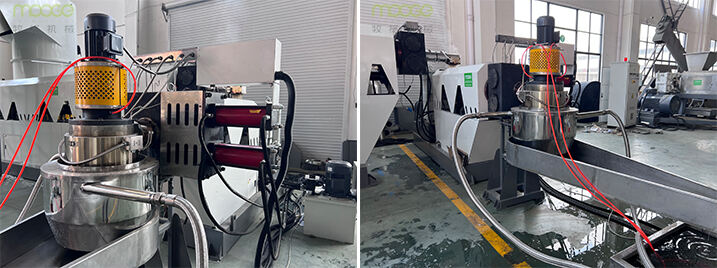

Manufactured with high-quality materials and technology is advanced insures sustainability and effectiveness. The product is sold by having a cutter is high-performance can manage a number of plastic materials, including PE and PP.

One of several key top attributes of the product is its capacity to recycle waste that plastic top-quality pellets being perfect for an array of applications. These pellets can be used as garbage when considering to production of plastic items and services, including toys, containers, and also other items for the house.

Fashioned with ease-of-use in the mind. The gear could be simply operated by anyone, apart from their number of experience. The system is user-friendly control is easy help it be simple to adjust the device's settings and achieve the desired results.

Efficient and economical. It consumes actually power sources are little creates minimal waste, rendering it a great solution for businesses attempting to measure their carbon impact right back and reduce their operating costs.

Why wait? Ensure you get your MOOGE Recycled PP PE Plastic Pelletizing Recycling Ldpe Film Plastic Granulator device and begin saving our planet while also spending less today.