×

×

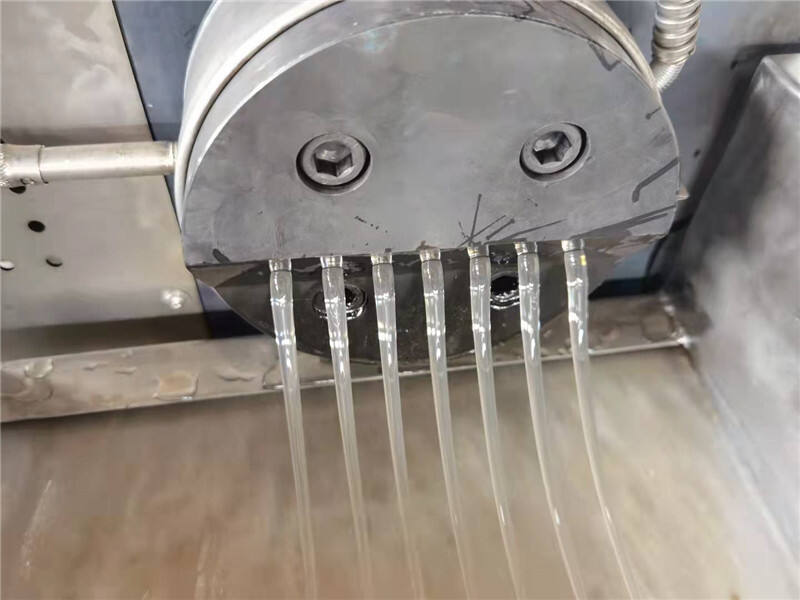

The MOOGE PP PE Pet Plastic Pelletizing Machine / Waste Plastic Recycling Machine / Plastic Granulators is a state-of-the-art waste plastic recycling equipment that can efficiently process PP, PE, PET and other types of plastic materials into high-quality pellets. This machine is perfect for any plastic granulating application, and it is built to deliver superior performance while requiring minimal maintenance.

Created from top-notch materials and designed with precision engineering, developed to withstand the rigors of industrial use. It features advanced level heating and systems that are cooling ensure consistent production of uniformly-shaped pellets. Using its advanced controls and design that is user-friendly it's effortless to operate and produces quality outputs every time.

Made for large-scale recycling that is plastic, capable of processing big volumes of waste plastic materials into usable granules. This would be the ultimate waste plastic recycling machines with its powerful motors, accuracy cutting blades, and efficient filtration.

Can process a variety of plastic materials, including HDPE, LDPE, PET, PP, PS, PVC and others. The granules produced can be utilized for a numbers of different applications, from injection molding to extrusion, blow molding, and other manufacturing that is plastic.

These are an ideal solutions whether you are processing waste plastic materials from commercial or household sources. They are highly efficient, cost-effective, and built to last, making them ideal selections for any plastics operation that is recycling.

You can't only recycle waste that is plastic also contribute up to a cleaner environment. By reducing the total amount of plastic waste in landfills, you're assisting to preserve our resources which can be normal protect the planet.

So if you are in need of a reliable and efficient plastic pelletizing machine or plastic granulators, look no further than MOOGE. With its cutting-edge technology, precisions engineering, and superior performances, the MOOGE PP PE Pet Plastic Pelletizing Machine / Waste Plastic Recycling Machine / Plastic Granulators are the ultimate solutions for all your recycling needs.

Model |

Screw Diameter |

Rotary Speed |

Main Motor Power |

Capacity |

TDY-SJ50 |

50 mm |

500/600rpm |

37/45KW |

20-150kg/hr |

TDY-SJ65 |

65mm |

500/600rpm |

55/75KW |

100-300kg/hr |

TDY-SJ75 |

75mm |

500/600rpm |

90/110KW |

300-600kg/hr |

TDY-SJ90 |

90mm |

500/600rpm |

220/250KW |

600-1000kg/hr |