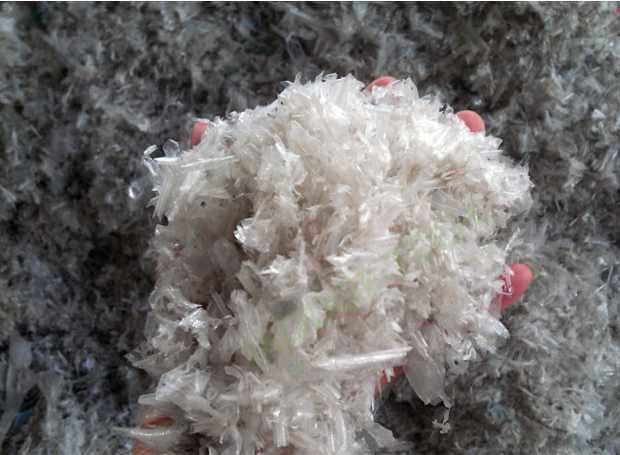

plastic waste materials recycling and making pellet, such as PP, PE,HDPE, LDPE, LLDPE film and clean woven/non woven bag materials,etc.The film can be pressed in compressor and then be pelletized.

×

×

Brand: MOOGE

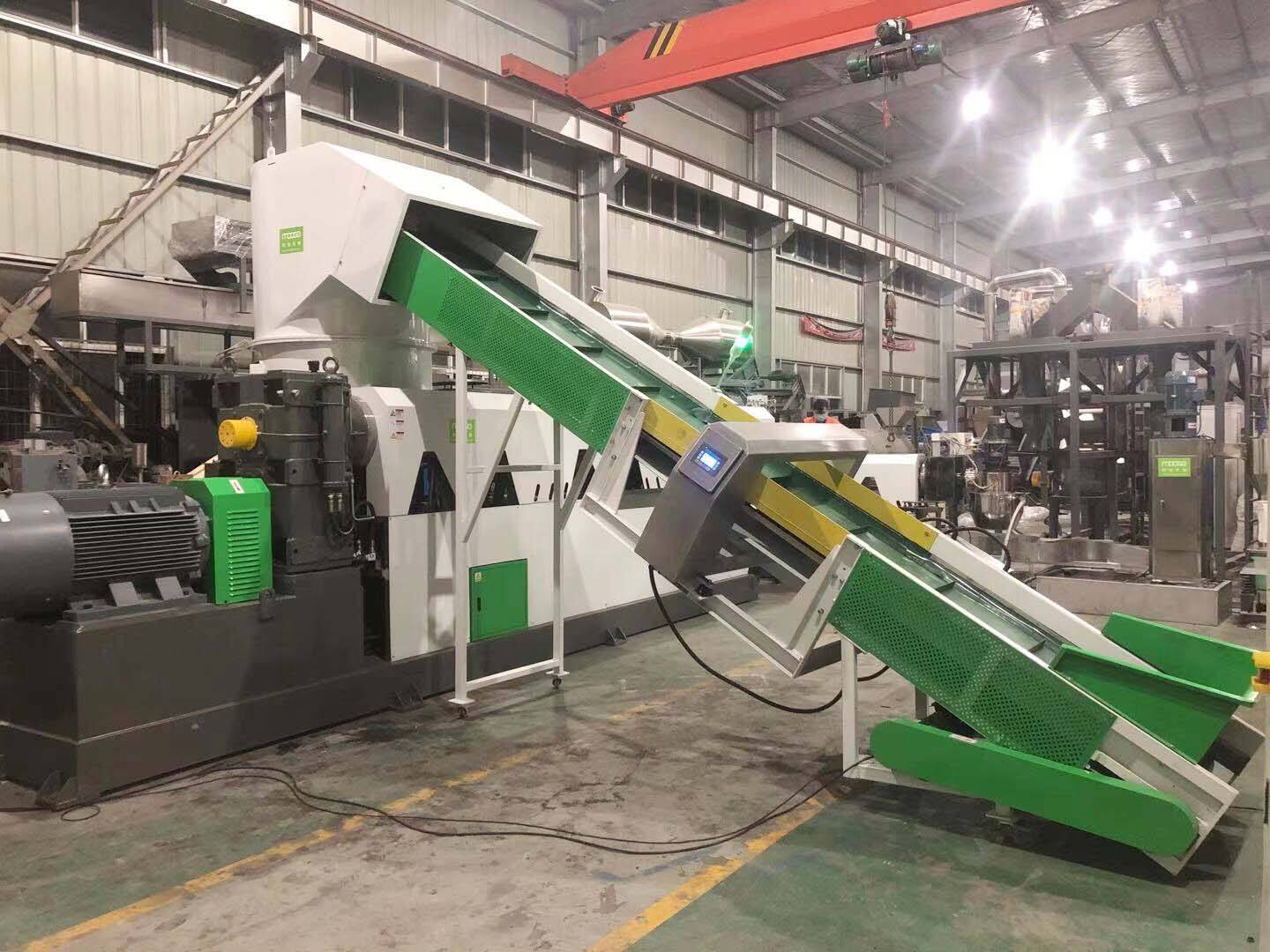

Introducing the MOOGE Waste Plastic Recycling Granulating Machine – a solution this is recycling that is undoubtedly eco-friendly waste material and this can be often discarded and left to pollute environmental environments.

This machine this is certainly innovative created to transform waste that is synthetic into reusable granules used to build solutions. The MOOGE granulating device has technology that is state-of-the-art will effectively process a variety this is certainly wide of materials, including HDPE, LDPE, PP, PVC, and PET.

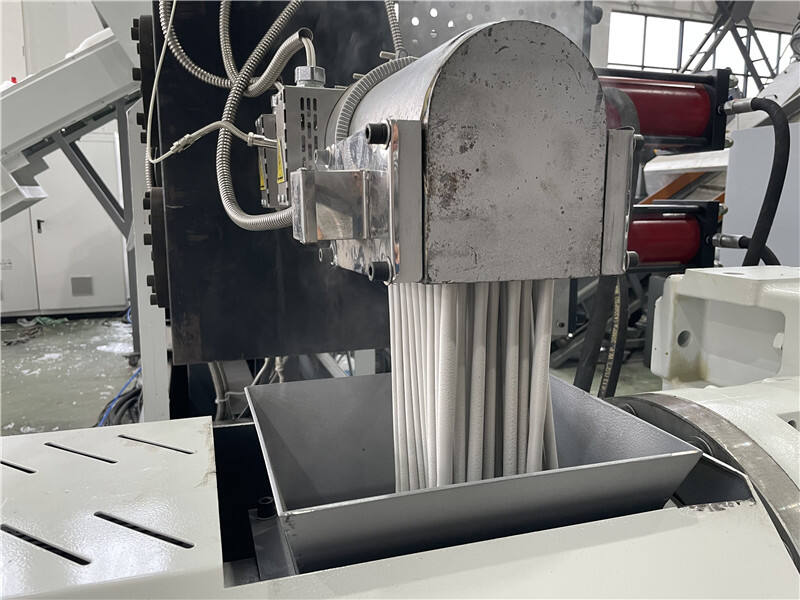

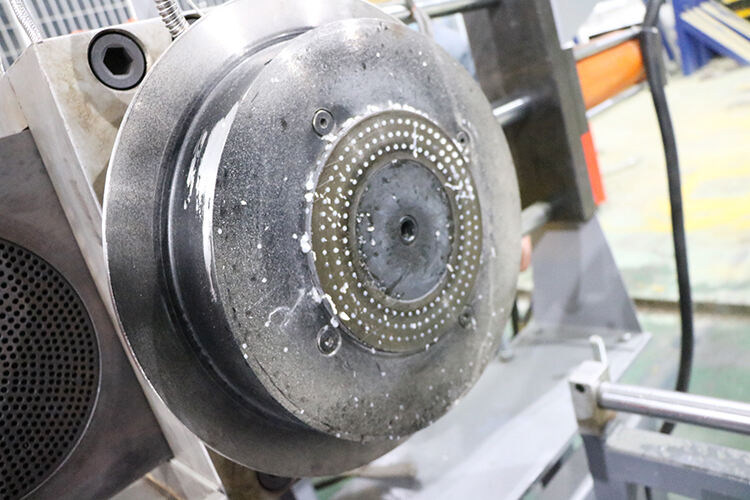

The machine employs a granulation that is very efficient that guarantees minimal waste and output that is optimum. It operates having a screw that is level that is high combination system that ensures constant and granule that is precise, also the entire process can be carried out totally immediately, making it ideal for high-volume manufacturing.

The MOOGE granulating device could be really user-friendly also. It comes down designed with a screen that is user-friendly permits users to easily operate and get a handle on the apparatus. The apparatus can also be a task that is easy neat and continue maintaining, and its lightweight design allows for effortless transportation and storage space.

The MOOGE granulating machine could also be incredibly eco-friendly in addition to its level that is technology that is advanced features. By recycling spend that is synthetic it shall assist to lessen the quantity of plastic that results in landfills and oceans, therefore decreasing the effect that is negative of in experience of environment.

Model |

Screw Diameter |

Screw L/D |

Main Motor Power |

Capacity |

RDS-SJ85 |

85mm |

28-33:1 |

55KW |

150-200kg/hr |

RDS-SJ100 |

100mm |

28-33:1 |

75KW |

200-300kg/hr |

RDS-SJ130 |

130mm |

28-33:1 |

90KW |

300-400kg/hr |

RDS-SJ150 |

150mm |

28-33:1 |

110KW |

400-500kg/hr |

RDS-SJ160 |

160mm |

28-33:1 |

132KW |

500-600kg/hr |

RDS-SJ180 |

180mm |

28-33:1 |

160KW |

600-800kg/hr |

RDS-SJ200 |

200mm |

28-33:1 |

200KW |

800-1000kg/hr |

Model |

Screw Diameter |

Screw L/D |

Main Motor Power |

Capacity |

RSS-SJ85 |

85mm |

28-33:1 |

55KW |

150-200kg/hr |

RSS-SJ100 |

100mm |

28-33:1 |

75KW |

200-300kg/hr |

RSS-SJ130 |

130mm |

28-33:1 |

90KW |

300-400kg/hr |

RSS-SJ150 |

150mm |

28-33:1 |

110KW |

400-500kg/hr |

RSS-SJ160 |

160mm |

28-33:1 |

132KW |

500-600kg/hr |

RSS-SJ180 |

180mm |

28-33:1 |

160KW |

600-800kg/hr |

RSS-SJ200 |

200mm |

28-33:1 |

200KW |

800-1000kg/hr |