×

×

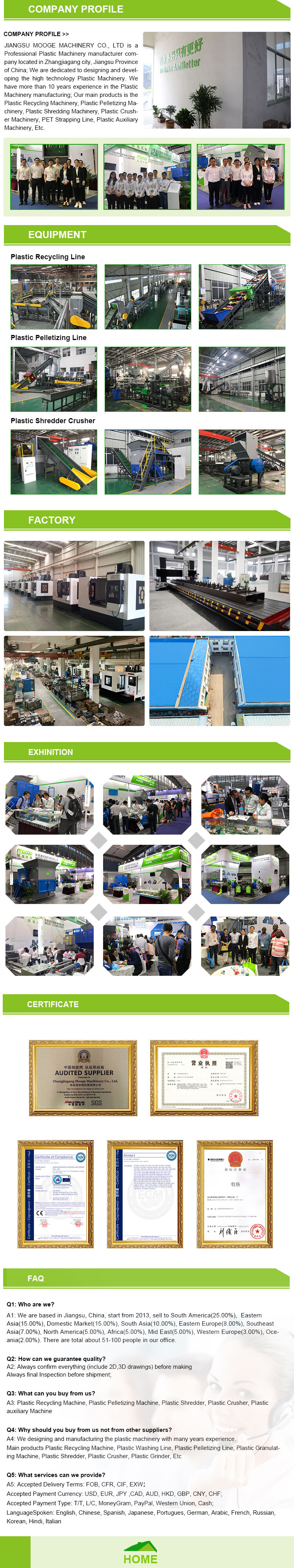

Model |

Capacity |

Installed Power |

Steam Use |

Water Supply |

Main power |

Area Required |

MT-500 |

500 kg/hr |

190 KW |

Optional |

4-5 m3/hr |

4-6 Person |

60*5*5 m |

MT-1000 |

1000 kg/hr |

260 KW |

Optional |

6-8 m3/hr |

8-10 Person |

80*8*5 m |

MT-2000 |

2000 kg/hr |

400 KW |

Suggest Use |

10-15 m3/hr |

10-12 Person |

80*8*5 m |

MT-3000 |

3000 kg/hr |

600 KW |

80,000 Kcal |

20-30 m3/hr |

12-16 Person |

100*8*10 m |

MT-4000 |

4000 kg/hr |

800 KW |

100,000 Kcal |

30-40 m3/hr |

15-20 Person |

135*10*10 m |

MT-5000 |

5000 kg/hr |

1000 KW |

120,000 Kcal |

40-50 m3/hr |

15-20 Person |

135*10*10 m |

Unit Energy Consumption |

||

Content |

Average energy consumption per ton of bottle |

|

Electricity |

70-90KW |

|

Water |

1-1.5T/hr |

|

Compressed air |

0.5-1m3 |

|

Steam (optional) |

250-400KG |

|

Detergent (optional) |

4-8KG |

|

Bottle Flakes Quality Reference |

||

Technical Parameter |

Specifications |

|

Flakes size |

12-14mm |

|

Moisture Content |

<1%<> |

|

PVC Content |

Less than 100 ppm |

|

PH |

7.5 +/- 0.5 |

|

Intrinsic Viscosity |

> 0.70 |

|

Non-PET |

Less than 100 ppm |

|

Color PET |

Less than 150 ppm |

|

Bulk density |

250-400 kg/m³ |

|

Suitable to be used for |

Polyester/ PET strapping/ Polyester Fiber/ PSF/ PET Sheet |

|

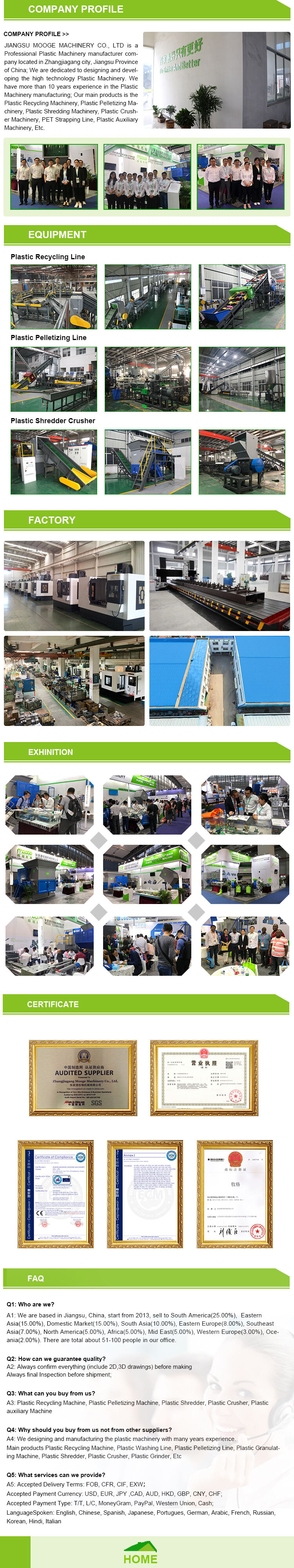

MOOGE

Plastic PET Bottle Scrap Crushing Hot Wash Recycling Machine Line is truly a top-quality recycling designed to assist you to efficiently recycle your plastic waste. With this particular recycling machine, it is possible to turn your synthetic waste into what to lessen your ecological footprint and improve your revenue margins.

The MOOGE Plastic PET Bottle Scrap Crushing Hot Wash Recycling Machine Line is actually specifically made to provide a very good and efficient solution is recycling all types of plastic PET bottles. The unit features an effective shredder that can simply break the bottles on to tiny pieces.

The hot wash in this Plastic PET Bottle Scrap Crushing Hot Wash Recycling Machine Line guarantees that most plastic bottle debris is removed ahead of the bottles go into the recycling process. This process uses hot water wash the bottles and remove dirt, labels, along with other contaminants.

The MOOGE Plastic PET Bottle Scrap Crushing Hot Wash Recycling Machine Line has a top-quality system is drying helps to make sure the plastic PET bottles are thoroughly dried before these are typically processed. This can help to make sure that the recycled materials of a constant quality could be used to produce high-quality synthetic products.

The MOOGE Plastic PET Bottle Scrap Crushing Hot Wash Recycling Machine Line is an easy task operate and keep. The equipment is equipped having a user-friendly control that allows one to begin preventing the machine as necessary. Also, due to its modular design can easily replace parts and perform maintenance about the machine without the need for a technician.