×

×

Pelletizing Machine Model |

RSS |

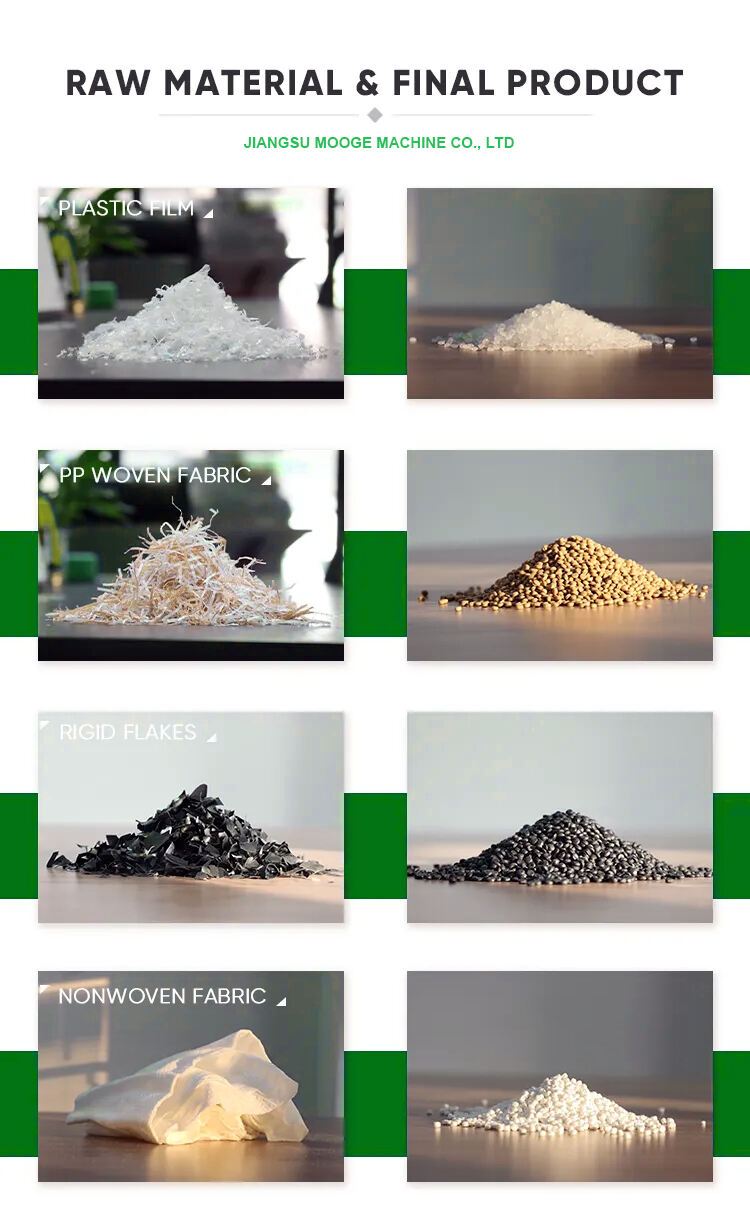

Recycling Material |

LDPE, LLDPE, HDPE, PP, BOPP, CPP, EPS, PS, PPS, ABS, PA, PLA |

Pelletizing Machine Capacity |

200-1200KG/H |

Pelletizing Screw Diameter |

80-200MM |

Screw Design |

Single Screw |

Granulator L/D Ratio |

33-44/1 |

Granulating Screw Rpm |

90-180 |

Screw Material |

38CrMoAl |

Gearbox Brand/type |

BONENG Brand/ High Torque Vertical |

Pelletizing Line Motor Brand |

SIEMENS / WEG |

Degassing Zone |

2 |

Pelletizer type |

Water ring pelletizer |

Total Power |

150-650KW |

Delivery Time |

60-70 days |

Pelletizing Machine Warranty Time |

12 months |

Recycling Pelletizing Certificate |

CE |

Technology Parameter |

Technology Parameter |

|||||||||||

Pelletizing |

Type |

SJ-100 |

SJ-120 |

SJ-150 |

SJ-180 |

SJ-200 |

||||||

Granulator |

Capacity (kg/h) |

200-300 |

300-400 |

400-500 |

600-800 |

800-1000 |

||||||

Energy consumption (kWh/kg) |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

|||||||

Exturder

|

Screw Diameter (mm) |

Φ100 |

Φ120 |

Φ150 |

Φ180 |

Φ200 |

||||||

L/D |

33-44/1 |

33-44/1 |

33-44/1 |

33-44/1 |

33-44/1 |

|||||||

Motor power (kW) |

75 |

90 |

110 |

160 |

200 |

|||||||

Filter

(options)

|

Two position plate type |

● |

● |

● |

● |

● |

||||||

Two position piston type |

○ |

○ |

○ |

○ |

○ |

|||||||

Back flush piston type |

○ |

○ |

○ |

○ |

○ |

|||||||

Automatic self-cleaning type |

○ |

○ |

○ |

○ |

○ |

|||||||

2nd Extruder

(optional)

|

Screw Diameter (mm) |

Φ100 |

Φ120 |

Φ150 |

Φ180 |

Φ200 |

||||||

L/D |

8-12/1 |

8-12/1 |

8-12/1 |

8-12/1 |

8-12/1 |

|||||||

Motor power (kW) |

30 |

45 |

55 |

75 |

90 |

|||||||

Downstream (options)

|

Water ring pelletizer |

● |

● |

● |

● |

● |

||||||

Strand pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

Automatic strand pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

Underwater pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

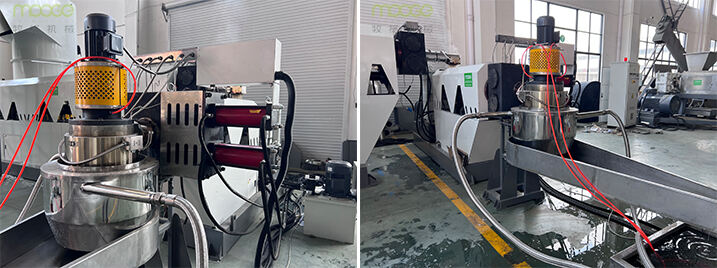

MOOGE

Plastic Pellet Pe making Pp Line Wast Film Recycling Pelletizing device is just a product is high-performance is made to assist you to recycle plastic movie waste and convert it into reusable plastic pellets. This state-of-the-art machine is made become easy to utilize and keep maintaining, also to deliver results which can be reliable time.

Created from top-quality materials which will withstand the rigors of heavy-duty use. The machine ended up being designed to final and so can manages many plastics, including PE, PP, and far more. The apparatus could be created to be energy-efficient, assisting you save cash on electricity costs while cutting your carbon impacts.

Perfect for all industries, including plastics recycling, productions, and much more. The machine was created to be versatile and that can be utilized in terms of number of applications, for instance the productions of top-notch plastic is recycled you should use for injection moldings, extrusions, along with other procedures.

The solution is perfect tiny and medium-sized companies attempting to enhance their synthetic recycling capabilities featuring its robust design and easy-to-use settings. The apparatus is straightforward to function and needs training is minimal which enables you to include to the operations are existing.

Why wait? Decide to try the MOOGE Plastic Pellet Pe making Line pp Wast Recycling Pelletizing Machine today and begin building a differences.