×

×

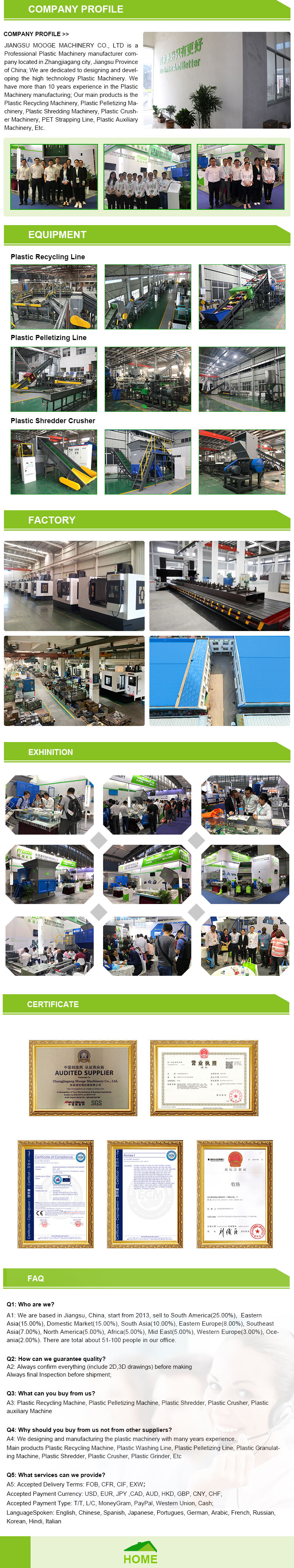

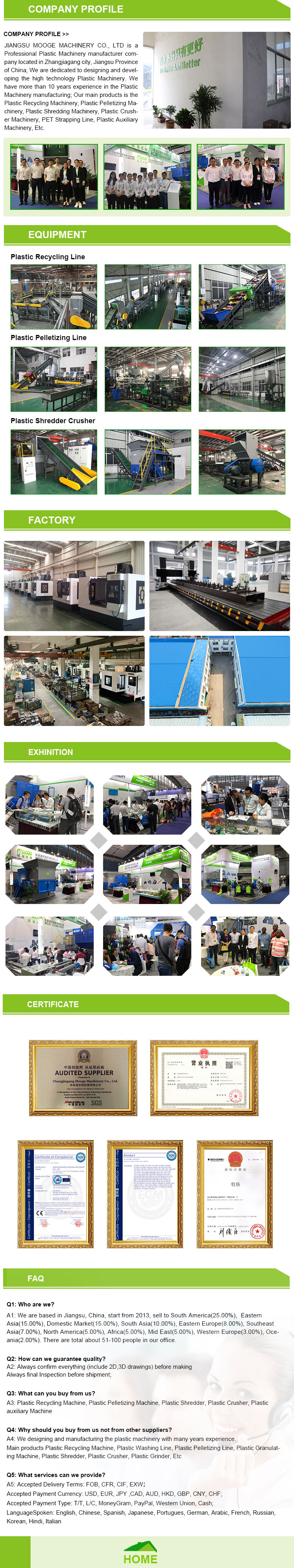

MOOGE

Establishing the PET Bottle Scraps Plastic Crushing Washer Recycling Machine Line the service excellent changing used plastic compartments right in to trustworthy, excellent rubbish.

This revolutionary tool recycling is developed towards easily crush cleanse creature bottle scraps, changing all of them right in to nice recyclable artificial pellets. The PET Bottle Scraps Plastic Crushing Washer Recycling Machine Line makes that every compartment is easily ready cleaned, causing excellent product reused you should utilize when it concerns volume of creation uses including its own higher-level innovation.

Produced companies of a lot of dimensions, the goods line attributes a selection large of the are customized towards accommodate the finish demands of your business.

Beginning along with the crushing machine, which successfully shreds grinds your furry buddy compartments right in to much smaller items, each tool succeeding the line is developed towards more fine-tune cleanse the products. The MOOGE washer makes use of sprinkle helpful towards blast away dirt particles, although the wandering storage container removes pollutants just like caps, tags, various other non-PET products.

The MOOGE PET Bottle Scraps Plastic Crushing Washer Recycling Machine Line makes that every compartment is entirely cleaned prior to you go into the drying out pelletizing period possessing its own consistent washing device cleaning. This is where the shredding tool densifying right in to participate in, modifying the cleaned product right in to totally defined sized collection pellets to become used in a ton of creation uses.

On the listing of possibilities distinct possess all of the PET Bottle Scraps Plastic Crushing Washer Recycling Machine Line is its own display straightforward produces it quick and easy towards manage each tool towards accommodate your specific production demands. Including its own instinctive environments personalized environments, you manage to readjust the cost, warmth, various other elements towards make sure your reused item is relating to the High-Quality ultimate.

The PET Bottle Scraps Plastic Crushing Washer Recycling Machine Line will be the excellent service whether you may be a Bit business wishing to minimize lose conserve cash a much larger technique preparation towards make lasting, environment-friendly things. The product line can be the excellent service towards completely enhance used plastic compartments as a vital composed information of top-level innovation, straightforward software program, excellent creation. Commit within the MOOGE PET Bottle Scraps Plastic Crushing Washer Recycling Machine Line towards view merely how it will aid your on the web company prosper today develop.

Model |

Capacity |

Installed Power |

Steam Use |

Water Supply |

Main power |

Area Required |

MT-500 |

500 kg/hr |

190 KW |

Optional |

4-5 m3/hr |

4-6 Person |

60*5*5 m |

MT-1000 |

1000 kg/hr |

260 KW |

Optional |

6-8 m3/hr |

8-10 Person |

80*8*5 m |

MT-2000 |

2000 kg/hr |

400 KW |

Suggest Use |

10-15 m3/hr |

10-12 Person |

80*8*5 m |

MT-3000 |

3000 kg/hr |

600 KW |

80,000 Kcal |

20-30 m3/hr |

12-16 Person |

100*8*10 m |

MT-4000 |

4000 kg/hr |

800 KW |

100,000 Kcal |

30-40 m3/hr |

15-20 Person |

135*10*10 m |

MT-5000 |

5000 kg/hr |

1000 KW |

120,000 Kcal |

40-50 m3/hr |

15-20 Person |

135*10*10 m |

Unit Energy Consumption |

||

Content |

Average energy consumption per ton of bottle |

|

Electricity |

70-90KW |

|

Water |

1-1.5T/hr |

|

Compressed air |

0.5-1m3 |

|

Steam (optional) |

250-400KG |

|

Detergent (optional) |

4-8KG |

|

Bottle Flakes Quality Reference |

||

Technical Parameter |

Specifications |

|

Flakes size |

12-14mm |

|

Moisture Content |

<1%<> |

|

PVC Content |

Less than 100 ppm |

|

PH |

7.5 +/- 0.5 |

|

Intrinsic Viscosity |

> 0.70 |

|

Non-PET |

Less than 100 ppm |

|

Color PET |

Less than 150 ppm |

|

Bulk density |

250-400 kg/m³ |

|

Suitable to be used for |

Polyester/ PET strapping/ Polyester Fiber/ PSF/ PET Sheet |

|