×

×

Model |

Capacity |

Installed Power |

Steam Use |

Water Supply |

Main power |

Area Required |

MT-500 |

500 kg/hr |

190 KW |

Optional |

4-5 m3/hr |

4-6 Person |

60*5*5 m |

MT-1000 |

1000 kg/hr |

260 KW |

Optional |

6-8 m3/hr |

8-10 Person |

80*8*5 m |

MT-2000 |

2000 kg/hr |

400 KW |

Suggest Use |

10-15 m3/hr |

10-12 Person |

80*8*5 m |

MT-3000 |

3000 kg/hr |

600 KW |

80,000 Kcal |

20-30 m3/hr |

12-16 Person |

100*8*10 m |

MT-4000 |

4000 kg/hr |

800 KW |

100,000 Kcal |

30-40 m3/hr |

15-20 Person |

135*10*10 m |

MT-5000 |

5000 kg/hr |

1000 KW |

120,000 Kcal |

40-50 m3/hr |

15-20 Person |

135*10*10 m |

Unit Energy Consumption |

||

Content |

Average energy consumption per ton of bottle |

|

Electricity |

70-90KW |

|

Water |

1-1.5T/hr |

|

Compressed air |

0.5-1m3 |

|

Steam (optional) |

250-400KG |

|

Detergent (optional) |

4-8KG |

|

Bottle Flakes Quality Reference |

||

Technical Parameter |

Specifications |

|

Flakes size |

12-14mm |

|

Moisture Content |

<1%<> |

|

PVC Content |

Less than 100 ppm |

|

PH |

7.5 +/- 0.5 |

|

Intrinsic Viscosity |

> 0.70 |

|

Non-PET |

Less than 100 ppm |

|

Color PET |

Less than 150 ppm |

|

Bulk density |

250-400 kg/m³ |

|

Suitable to be used for |

Polyester/ PET strapping/ Polyester Fiber/ PSF/ PET Sheet |

|

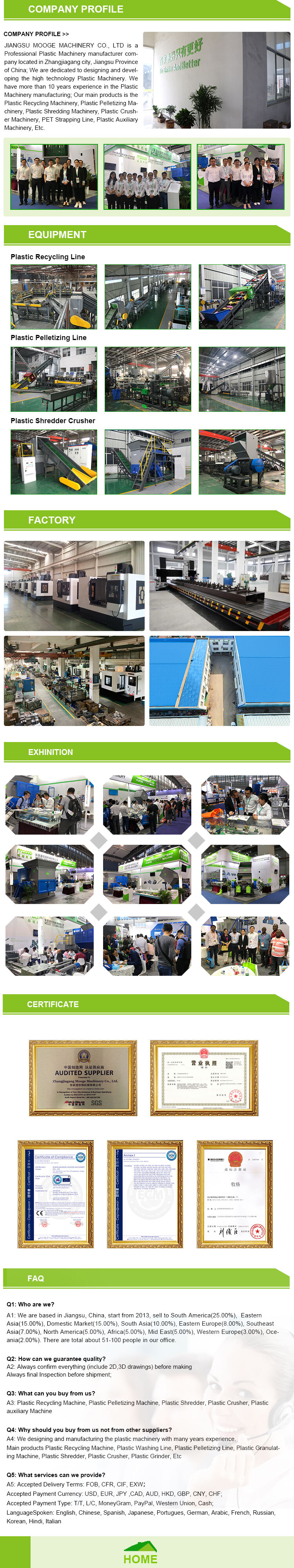

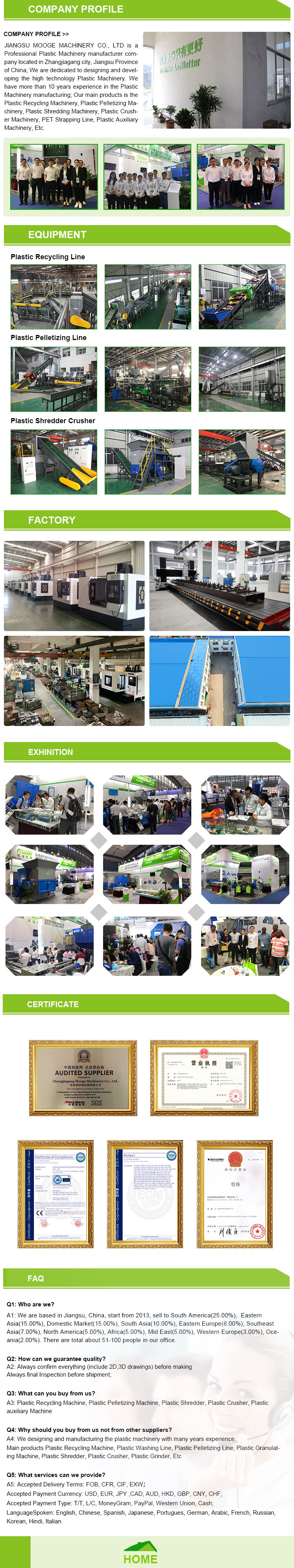

MOOGE

Searching for an eco-friendly solution recycle your PET bottles? Take a look at MOOGE's PET Bottle Plastic Crushing and Hot Washing Recycling Line. This innovative system built to greatly help people and businesses decrease their carbon footprint and do their component to safeguard the environmental surroundings.

The MOOGE PET Bottle Plastic Crushing and Hot Washing Recycling Line is incredibly an easy task to utilize. Simply place your furry friend bottles into the device and allow it to the heavy lifting. The device will crush the bottles into small pieces and then utilize hot water wash away any impurities. This process implies that the recycled material regarding the highest quality, which makes it ideal for reuse.

One of the greatest top features of this product is its incredibly efficient. The MOOGE PET Bottle Plastic Crushing and Hot Washing Recycling Line can process up to 2,000 kilograms of animal containers each hour, rendering it perfect for businesses of all sizes. It even offers a low energy rate and that means you will not have to worry about skyrocketing energy bills.

Another great feature of product is its durability. The MOOGE PET Bottle Plastic Crushing and Hot Washing Recycling Line is built to last, with a sturdy frame top-notch components that will handle possibly the recycling toughest jobs. In addition has allows interface are user-friendly to function and continue maintaining.

One of the best cause of the MOOGE PET Bottle Plastic Crushing and Hot Washing Recycling Line is its versatility. It may be used to recycle an amount of various PET products, including bottles, containers, and packaging materials. This will make it a perfect option for businesses in a wide array of companies, from meals and beverage to cosmetics and individual care.

Of course, probably one of the most important advantages of choosing the MOOGE PET Bottle Plastic Crushing and Hot Washing Recycling Line is its positive impact on environment. By recycling your PET products, you are able to lessen the quantity waste that leads to landfills and oceans. It will help protect wildlife, conserve resources, and promote a more sustainable future all.