×

×

Model |

Screw Diameter: mm |

Screw L/D |

Main Power: KW |

Capacity: Kg/h |

RDS-SJ 85 |

85 |

28-33:1 |

55 |

150-200 |

RDS-SJ 100 |

100 |

28-33:1 |

75 |

200-300 |

RDS-SJ 130 |

130 |

28-33:1 |

90 |

300-400 |

RDS-SJ 150 |

150 |

28-33:1 |

110 |

400-500 |

RDS-SJ 160 |

160 |

28-33:1 |

132 |

500-600 |

RDS-SJ 180 |

180 |

28-33:1 |

160 |

600-800 |

RDS-SJ 200 |

200 |

28-33:1 |

200 |

800-1000 |

Model |

Screw diameter: mm |

Screw L/D |

Main Power: KW |

Capacity: kg/h |

RSS-SJ 85 |

85 |

28-33:1 |

55 |

150-200 |

RSS-SJ 100 |

100 |

28-33:1 |

75 |

200-300 |

RSS-SJ 130 |

130 |

28-33:1 |

90 |

300-400 |

RSS-SJ 150 |

150 |

28-33:1 |

110 |

400-500 |

RSS-SJ 160 |

160 |

28-33:1 |

132 |

500-600 |

RSS-SJ 180 |

180 |

28-33:1 |

160 |

600-800 |

RSS-SJ 200 |

200 |

28-33:1 |

200 |

800-1000 |

MOOGE

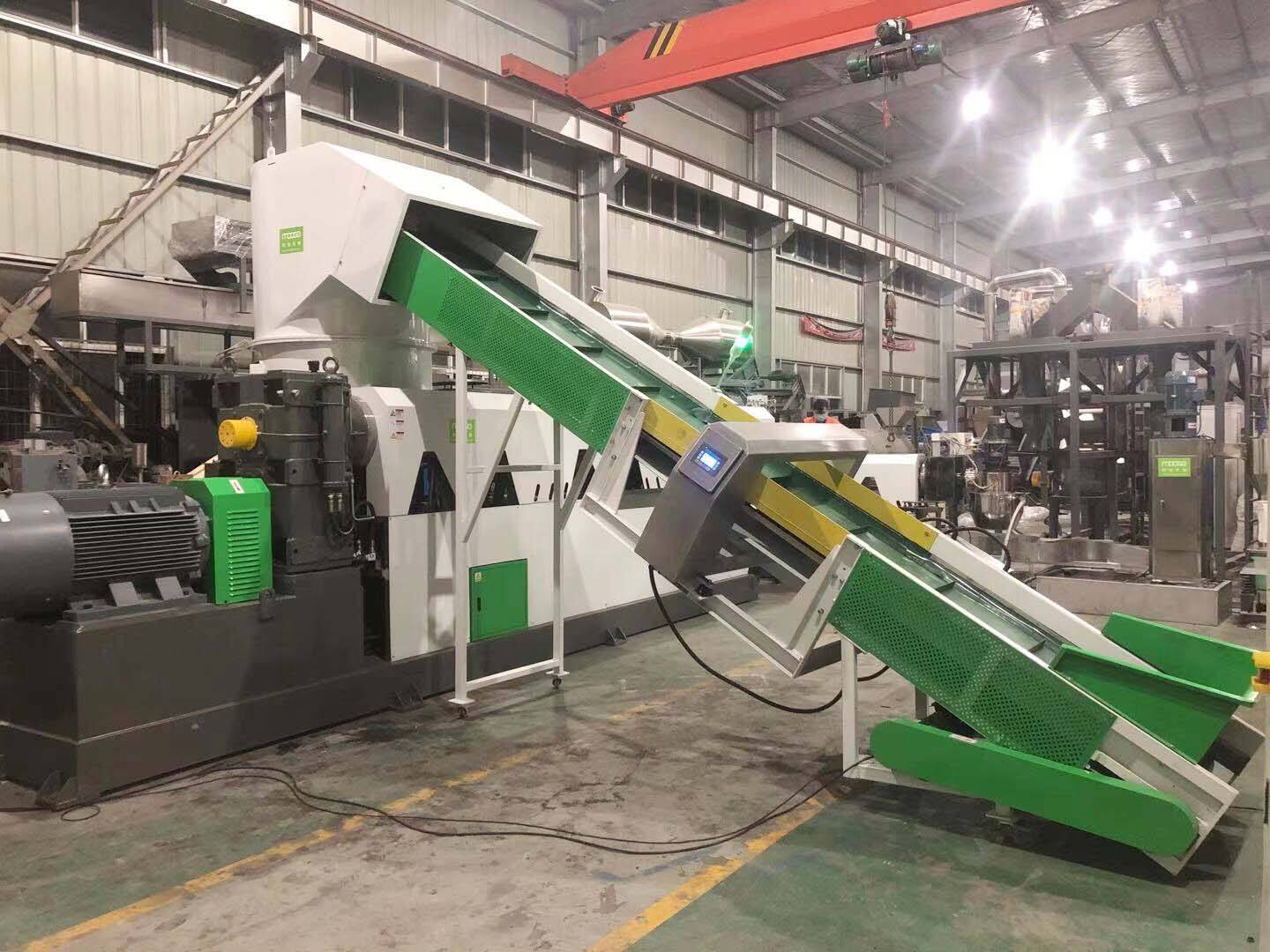

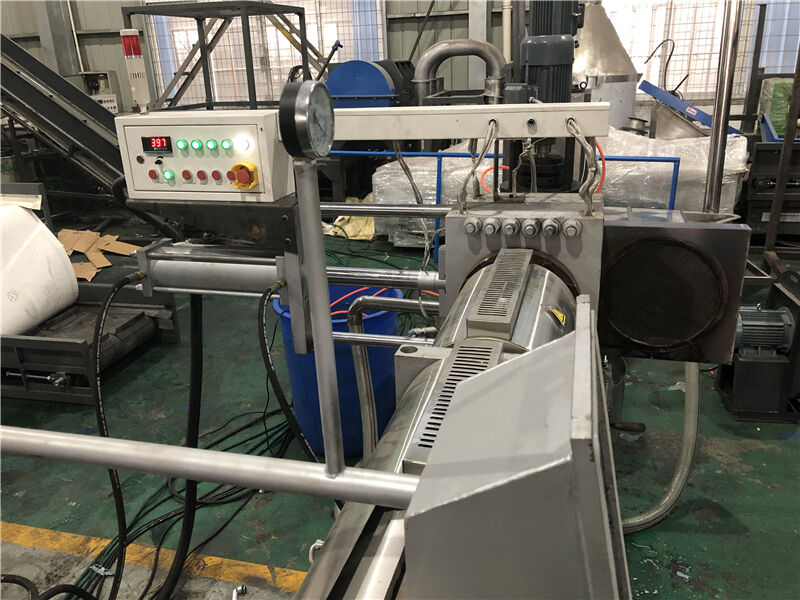

Searching for none top-notch PP PE HDPE LDPE Granules machine is making? Look any more than MOOGE. Our Plastic Pelletizing Granulator Machine may be the answer is recycling that perfect waste and making it useful and valuable granules.

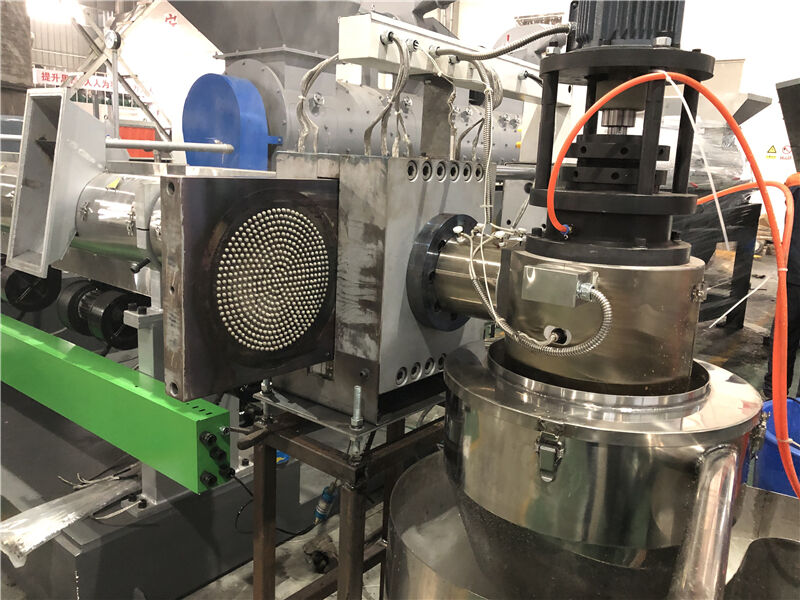

Straightforward to work alongside, reliable, and efficient. It comes down with an extruder is top-quality a motor is strong may process a big selection of plastic selection that wide of materials, including PP, PE, HDPE, and LDPE. All the way to 1000kg/h, this granulator device is well suited for both small and operations that may be large-scale with a production capacity.

Continuous system. This implies it's going to continue steadily to create granules without interruption you could feed waste is plastic to the device without stopping, and. This might make sure it is ideal for high-volume recycling operations, where efficiency speed are critical.

Designed for easy maintenance and operation. The control interface is user-friendly and intuitive, permitting operators to quickly and simply adjust the settings to attain the production is required. The apparatus normally easy to clean and continue maintaining, making sure it operates reliably and effectively through the entire long-lasting.

Along which consists of performance and reliability, our Non Stop PP PE HDPE LDPE Granules Machine is making additionally environmentally friendly. By recycling waste is synthetic it is possible to reduce your impact that ecological and to an even more future is sustainable. Plus, the granules generated by our device works extremely well in a number is wide of, including in the manufacture of brand new services are synthetic products.

Why wait? E mail us to discover more about this revolutionary and product is sustainable today.