×

×

MOOGE

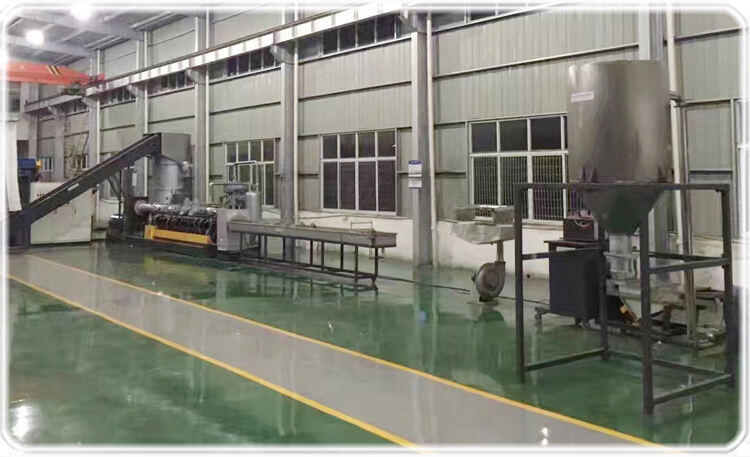

Interested in a convenient and way this is certainly recycle is economical fibers and produce top-quality polyester yarn? Look absolutely no further than the MOOGE Polyester Yarn PET Fiber Recycling Machine.

This advanced recycling machine is built too efficiently and effectively process animal fiber waste into top-quality polyester yarn, reducing waste and saving you money when you look at the act. This machine is the perfect choice for any company trying to improve its environmental impact and minimize its production costs which consists of advanced technology and dependable, durable construction.

The MOOGE Polyester Yarn PET Fiber Recycling Machine is run on advanced automation and control systems, ensuring constant and processing is precise of variety of PET spend. The apparatus includes a large ability storage bin and automatic feeding system, permitting continuous procedure and efficiency is maximum.

The MOOGE Polyester Yarn PET Fiber Recycling Machine can certainly be incredibly easy to use and continue maintaining in addition to its advanced features and construction is top-quality. Its intuitive software and design that user-friendly it simple even for novice operators to quickly and easily operate the machine and maintain steadily its operation.

Model |

Screw Diameter |

Screw L/D |

Main Motor Power |

Capacity |

PSF-SJ100 |

100 mm |

35:1 |

75 KW |

150-200 kg/hr |

PSF-SJ130 |

130 mm |

35:1 |

905 KW |

300 kg/hr |

PSF-SJ160 |

160 mm |

35:1 |

110 KW |

500 kg/hr |

PSF-SJ180 |

180 mm |

35:1 |

160KW |

600 kg/hr |

PSF-SJ200 |

200 mm |

35:1 |

200 KW |

800 kg/hr |

Crusher Machine

Function: Crushing the waste PET fiber/polyester yarn into small pieces for further processing

Compacting force feeder

Function: With multi blades further crushing and forcedly compressing the material into extruder

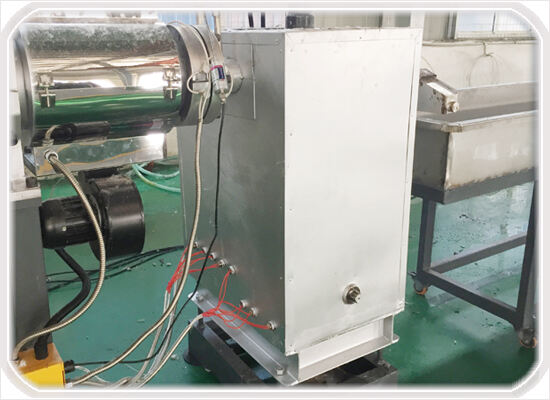

Single screw extruder

Function: Plasticizing the material with high temperature

Roots vacuum degassing system

Function: Exhausting the moisture with vacuum pump system

CPF screen filter

Function: Filtering material impurity

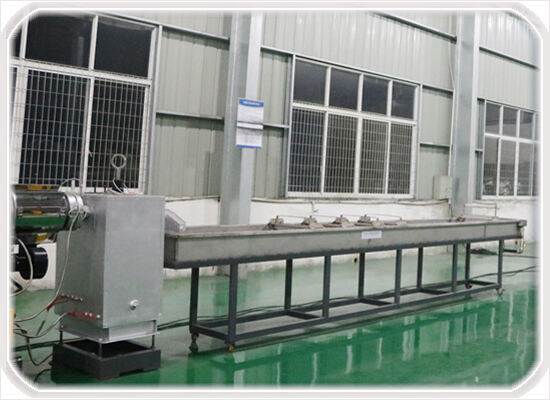

Water cooling tank

Function: Cooling the material with cold water

Pelletizer machine

Function: Cutting the material into pellets

Air conveying system and Silo

Function: Blowing pellets into the silo for storage

We attend the Chinaplas Exhibition every year (In Shanghai and Guangzhou) and take with our machine for test run at the booth. Besides, we also attend the plastic exhibition in other countries such as Mexico, Turkey, Egypt, Russia, Malaysia, etc. Please kindly contact with us in advance if you also have time to attend, sincerely welcome to our booth for visit and discuss about detailed issues.

• Pre-sale: we give our client the detailed technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

In order to match your requirement and provide you a proper quotation, please advise:

• What material do you want to recycle? POY? PSF? DTY? Or other material?

• What capacity (kg/h) do you want?

• What is the final size (mm) of flakes you want?

• Other special requirements about the polyester fiber pelletizing machine you want.