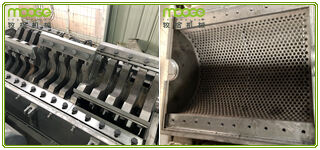

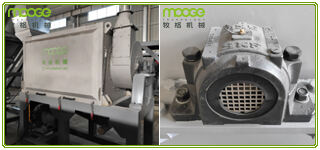

>Bearing house is installed outside of the chamber so no dirty goes inside which prolong the lifespan

> Upside hopper is covered by shelter so no flakes popped out.

×

×

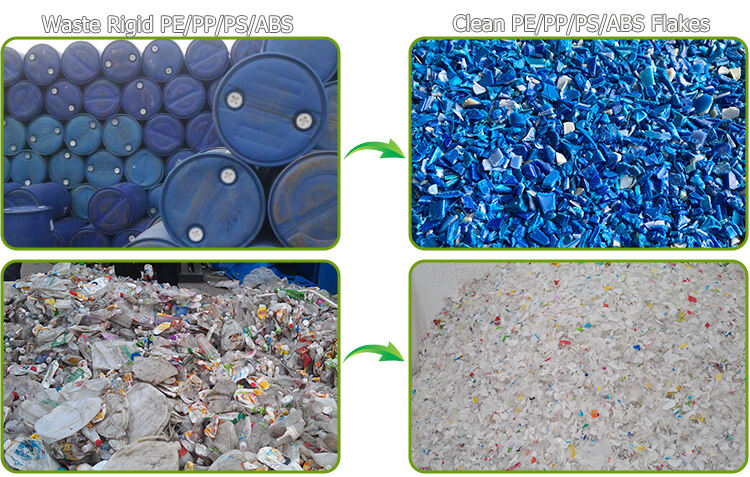

The MOOGE Hdpe Pp Ps Bottle Washing Rigid Pe Plastic Recycling device is a cutting-edge, efficient, and solution that is synthetic recycling that is dependable. This devices utilizes polyethylene that is high-densityHDPE), polypropylene (PP), polystyrene (PS), and polyethylene that is rigidPE) materials to produce a myriad of stuff like synthetic containers, toys, and containers. This recycling device had been made to assist businesses reduce their effects which are ecological additionally saving them cash on the way.

A totally automated system this is really an task that is not hard make use of. It may manage equally as much as 1,000kg of synthetic waste each complete hour, rendering it perfect for businesses that produce large quantities of synthetic waste. The gear carries a procedure that is eliminates which are pre-washing dust or debris through the synthetic before it gets to the washing procedure that is primary. This implies the synthetic that is recycled of the standard this is really greatest.

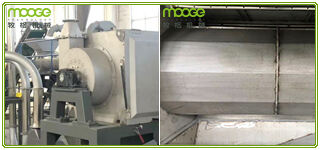

The washing this is really primary is made of a few stages. The phase that is very first a hot water clean water that is hot} to remove any staying dirt and contaminants. The synthetic then passes by way of a friction washer that removes any labels which can be glue that is remaining. The period that is next a separation that is sink-float that separates the synthetic from various other materials like steel or cup. The synthetic will probably be passed and dry up using a metal detector before being held in a silo for further processing.

One among the matter that is essential will be in a position to create synthetic that is top-quality is recycled. A mix is needed due to the unit of hot washing, friction washing, and separation procedures to make synthetic this is actually without the contaminants and in a position to be positioned in brand new things. Which means businesses can reduce their reliance on virgin synthetic while making utilization of synthetic that is recycled, which will be way better when it comes down to environment.

That is additionally economical along side its advantages being ecological. Businesses can help save money by recycling their synthetic this is really waste that is very own of the latest materials being synthetic. Recycling synthetic also assists companies avoid fines which are expensive waste that is incorrect, rendering it a investment this is actually smart any company.

Overall, the MOOGE Hdpe Pp Ps Bottle Washing Rigid Pe Plastic Recycling device is just a trusted, efficient, and solutions which can be economical synthetic recycling. Its automatic procedures and production that is top-quality that it is a great asset for almost any business that produces waste that is synthetic. Utilizing the MOOGE label of plastic equipment that is recycling companies is likely to make a impact that is confident the surroundings whilst also benefiting their base lines.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5m |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5m |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5m |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5m |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5m |

Item |

Specification |

Raw Material |

Waste Rigid Plastic PE bottle, HDPE barrel, PP bucket, PS Box, ABS shell, etc |

Finished Product |

Clean dry plastic flakes (size can be recycled as buyer request) |

Main Machine List |

Belt Conveyor, Shredder, Crusher, Cold Washing Tank, High Speed Friction Washer, Hot Washing Tank, Centrifugal Dryer, Hot Air Pipeline, Packing Silo |

Machine Material |

Machine frame is made by carbon steel, the machine washing part is made by SUS 304 |

Main Components |

NSK/SKF bearing, TTO oil sealing, Guomao reducer,etc. |

Electric Components |

ABB/Delta inverter, Omron temperature meter, Schneider contactor, Chint switch, Siemens made in China motor, etc. |

Warranty Period |

One Year from the Machine Operation within 18 Months from the B/L Date |

Turnkey After Service |

Technical Support including the machine layout, electric diagram, working manual, engineer available to buyer's factory overseas for helping installation, commissioning, training workers, etc. consumable parts provided; 24-hours online after sale service; |