×

×

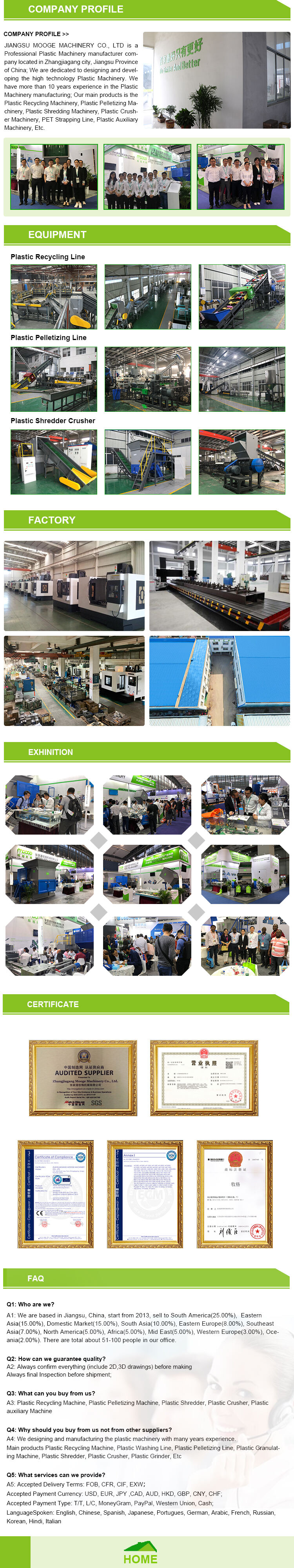

MOOGE

Has you covered utilizing their Hard Plastic Scrap Recycling Washing Line if you should be finding a reliable and reliable method to recycle difficult scrap is plastic? The merchandise is built to streamline the complete means of recycling hard scrap is synthetic ensuring top-notch output with only minimal effort.

The MOOGE Hard Plastic Scrap Recycling Washing Line is manufactured with durable materials to create certain performance is durable. The line includes a couple of key components, including a crusher, a washer, a device is obviously dewatering a heat dryer, and a combination system. Dozens of elements is built to work seamlessly together, providing an answer is entire recycling difficult scrap that synthetic.

The crusher may be the component certainly first the MOOGE Hard Plastic Scrap Recycling Washing Line. This revolutionary product was created to split up big aspects of difficult scrap is synthetic smaller, more pieces are manageable. Following the scrap is broken down, it is in reality fed in to the washer, helping to make use of water to fully clean the plastic and take away any dirt, debris, or any other contaminants.

After the plastic is washed, it truly is fed to the dewatering machine, which removes water is excess the material. It really is an essential the main recycling procedure because an excessive amount of water really make a difference the standard of the products is last. When the plastic is adequately dried, it really is fed in to the air is hot, which dries the item completely.

If the synthetic is actually dried and beaten up, it really is prepared for the step is obviously final the technique: collection. The MOOGE Hard Plastic Scrap Recycling Washing Line features a group system making this and task is not hard gather and store your recycled product. This method might be individualized to meet your specific needs, whether you would like an ability is large container or even an inferior, more solution that compact.

Among the list of primary items that are superb the MOOGE Hard Plastic Scrap Recycling Washing Line is its simplicity of good use. This method is very user-friendly, with a person interface is not difficult makes it simple to function and adjust as required. Additionally, the line was made to be energy-efficient, it to lessen waste and protect the environment to enable you to feel good about making use of.

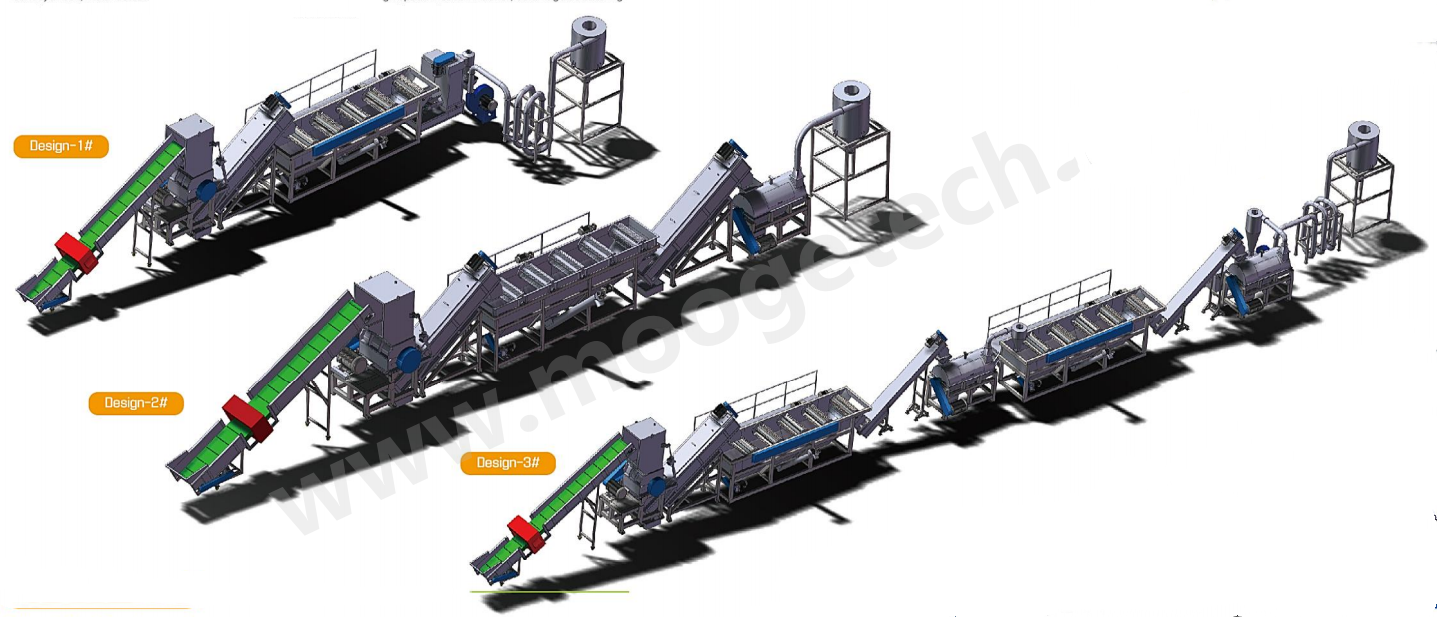

This RIGID PE PP PLASTIC WASHING LINE is used to recycling the waste HDPE/LDPE/PP bottles and buckets, hollow container and so on. The whole recycling line including the conveyor belt, metal detector, wet crusher, floating washing tank, high speed friction washer machine, centrifugal dewatering machine, hot air drying system and material collecting packing system. The waste dirty rigid pe pp bottles/buckets go through crushing, washing, drying, collecting process will turn to be clean flakes for further pelletizing. We also can customized the line components according to your special requirement.

Model |

Capacity |

Installed Power |

Water Supply |

Area Required :m |

MEB-300 |

300kg/hr |

100KW |

4-5m³/hr |

20*4.5*5 |

MEB-500 |

500kg/hr |

115KW |

5-6m³/hr |

20*4.5*5 |

MEB-1000 |

1000kg/hr |

125KW |

7-8m³/hr |

23*5*5 |

MEB-1500 |

1500kg/hr |

180KW |

8-10m³/hr |

25*5*5 |

MEB-2000 |

2000kg/hr |

225KW |

10-15m³/hr |

28*5*5 |

Model |

Capacity |

Installed Power |

Water Supply |

Area Required |

MEB-300 |

300kg/hr |

130KW |

5-6m³/hr |

38*4.5*5 |

MEB-500 |

500kg/hr |

145KW |

7-8m³/hr |

38*4.5*5 |

MEB-1000 |

1000kg/hr |

190KW |

8-10m³/hr |

42*5*5 |

MEB-1500 |

1500kg/hr |

230KW |

10-15m³/hr |

45*5*5 |

MEB-2000 |

2000kg/hr |

280KW |

15-20m³/hr |

45*5*5 |