×

×

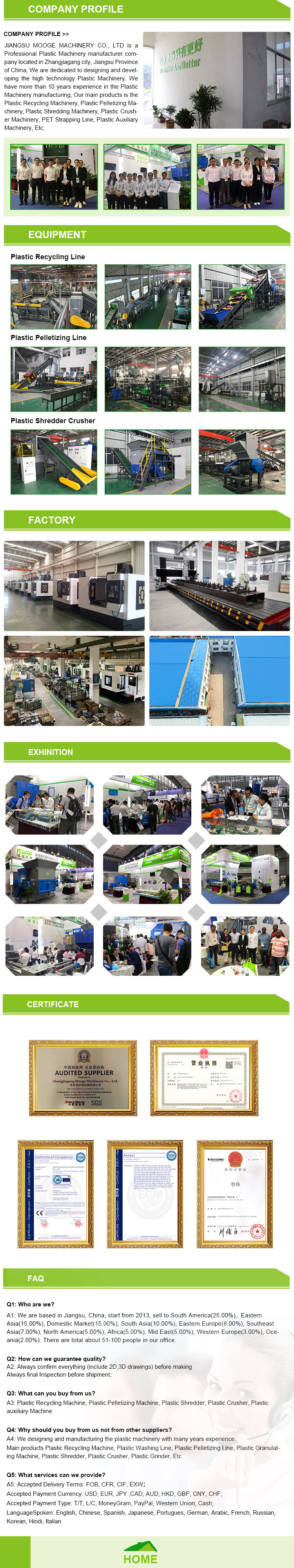

The China Manufacturing Pet Bottle Crushing Washing Drying Recycling Line may be an item outstanding to change utilized pet containers into reusable product. The item was made utilizing materials being top-notch guarantee its superior amounts, durability, and dependability.

This recycling line includes an array of devices, including a crusher, washer, and drier and a recycling tank when the materials are saved and prepared. The devices work with series, ensuring each step of the process regarding the process is carried out effortlessly and effortlessly. The crusher may be the very first device the containers move through, and it is really created to reduce them to little pieces which may be effortlessly washed during the stage next.

After crushing, the container pieces are then relocated to your washer, where they are completely washed. The washing includes the employment method of hot water which will help to eliminate any contaminants such as for example dust, oil, or oil. Water will be drained away, as well as the containers are carried in the drier.

The drier is within charge of getting rid of most of this water through the containers. It runs on the true quantity of fans to blow atmosphere hot the containers, ensuring all the dampness is eradicated, making them dry and prepared for the recycling tank. The recycling tank is within which the prepared animal bottles are kept after which it became reusable materials.

The China Manufacturing Pet Bottle Crushing Washing Drying Recycling Line is actually fashioned with the environmental surroundings in your head. It is a product assists that are eco-friendly easing polluting of the environment by recycling utilized bottles in place of permitting them to result in landfills. This product recycled be employed which will make other items such as for instance textiles, bags, and a lot more, causing this to be item a solution sustainable your preferences.

The merchandise is user-friendly, made to be an task easy run, and needs upkeep minimal. It comes down with step-by-step directions that guide users through the task set-up ensuring they are able to take advantage of it very nearly right away. It is usually been made from security in your mind, with safety features that assistance protect users from damage.

Model |

Capacity |

Installed Power |

Water Supply |

Main power |

Area Required |

MT-500 |

500 kg/hr |

190 KW |

4-5 m3/hr |

4-6 Person |

60*5*5 m |

MT-1000 |

1000 kg/hr |

260 KW |

6-8 m3/hr |

8-10 Person |

80*8*5 m |

MT-2000 |

2000 kg/hr |

400 KW |

10-15 m3/hr |

10-12 Person |

80*8*5 m |

MT-3000 |

3000 kg/hr |

600 KW |

20-30 m3/hr |

12-16 Person |

100*8*10 m |

MT-4000 |

4000 kg/hr |

800 KW |

30-40 m3/hr |

15-20 Person |

135*10*10 m |

MT-5000 |

5000 kg/hr |

1000 KW |

40-50 m3/hr |

15-20 Person |

135*10*10 m |

Unit Energy Consumption |

||

Content |

Average energy consumption per ton of bottle |

|

Electricity |

70-90KW |

|

Water |

1-1.5T/hr |

|

Compressed air |

0.5-1m3 |

|

Steam (optional) |

250-400KG |

|

Detergent (optional) |

4-8KG |

|

Bottle Flakes Quality Reference |

||

Technical Parameter |

Specifications |

|

Flakes size |

12-14mm |

|

Moisture Content |

<1%<> |

|

PVC Content |

Less than 100 ppm |

|

PH |

7.5 +/- 0.5 |

|

Intrinsic Viscosity |

> 0.70 |

|

Non-PET |

Less than 100 ppm |

|

Color PET |

Less than 150 ppm |

|

Bulk density |

250-400 kg/m³ |

|

Suitable to be used for |

Polyester/ PET strapping/ Polyester Fiber/ PSF/ PET Sheet |

|