MOOGE

Launching the HDPE PET PP Bottle Waste Plastic Shredder Grinder Crusher Machine, the clear answer perfect shrinking synthetic waste in your working environment. This item revolutionary made out of top-quality materials and made to manage perhaps the synthetic waste toughest.

This shredder grinder crusher machine is effective at shredding and grinding many synthetic materials, including MOOGE HDPE, PET, and PP containers featuring its more impressive range technology. The shredder is sold with effective blades at cutting through synthetic waste with simplicity, reducing the amount of waste material and rendering it much easier to be rid of.

The HDPE PET PP Bottle Waste Plastic Shredder Grinder Crusher Machine is easy to work with and run. Just load the waste synthetic the apparatus and permit it to do its work. The device will shred and grind the waste synthetic Bit, workable pieces, which makes it much easier to recycle or dump.

The unit normally safe to work with, insurance firms an array of security features meant to protect users from accidents or accidents. It comes down with a metal durable developed to final and withstand the requirements of hefty usage.

The HDPE PET PP Bottle Waste Plastic Shredder Grinder Crusher Machine can be made to be maintenance low therefore you invest less money and time on repairs and maintenance. This may allow it to be a good investment perfect organization trying to scale back their synthetic waste and spend less on disposal expenses.

If you’re buying a top-notch, reliable, and synthetic grinder affordable device, look no further as compared to HDPE PET PP Bottle Waste Plastic Shredder Grinder Crusher Machine. Alongside its revolutionary features, effective performance, and simplicity, it will be the right device for almost any company trying to reduce their synthetic waste and enhance their ecological impact. Never wait to get this technique and commence actions using a greener and much more future sustainable. Get the HDPE PET PP Bottle Waste Plastic Shredder Grinder Crusher Machine today.

S Series Plastic Crusher- For PET/PP/PE/HDPE Bottles, Buckets, Hollow Containers.

Used for the

PET bottle, Plastic Bottle, Buckets, Hollow Containers, and so on Plastic.Its With Special Structure Design, Will Have More Capacity With Less Power Consumption.

Main Features:

1. Frame is made by solid square tube steel.

2. Shaft is made by 45# steel with quenching treatment.

3. Chamber is made by solid steel 40 mm thickness.

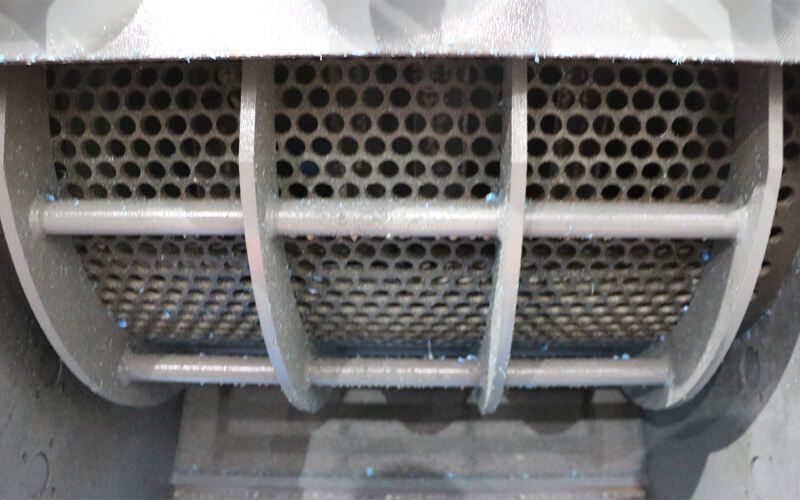

4. Screen mesh is made by 10 mm thick steel for durable use.

5. Easy-disassembling design, chamber is opened by motor automatically, which is simple and labor-saving to clean and maintain, and also convenient to change the blades.

6. Bearing house installed outside of the crusher chamber so no dirty goes inside which prolong the lifespan.

7. Machine upside chamber is higher and covered by belt no flakes popped out.

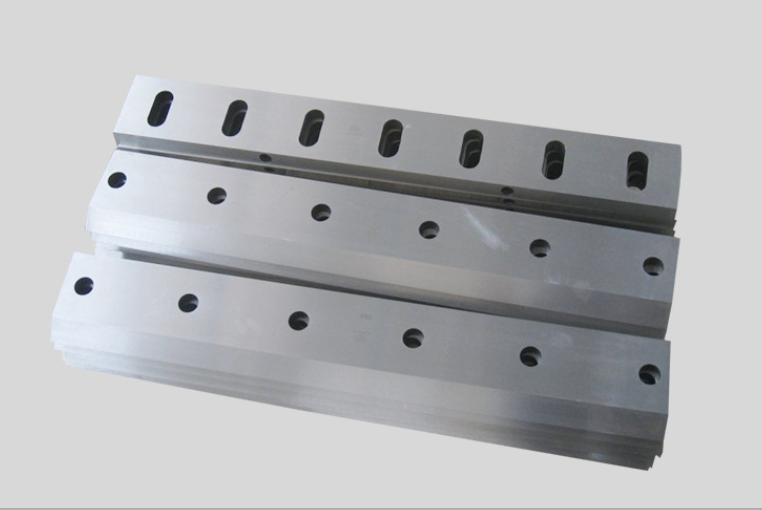

8. Blades are made by famous brand SKD-II from Japan with top quality.

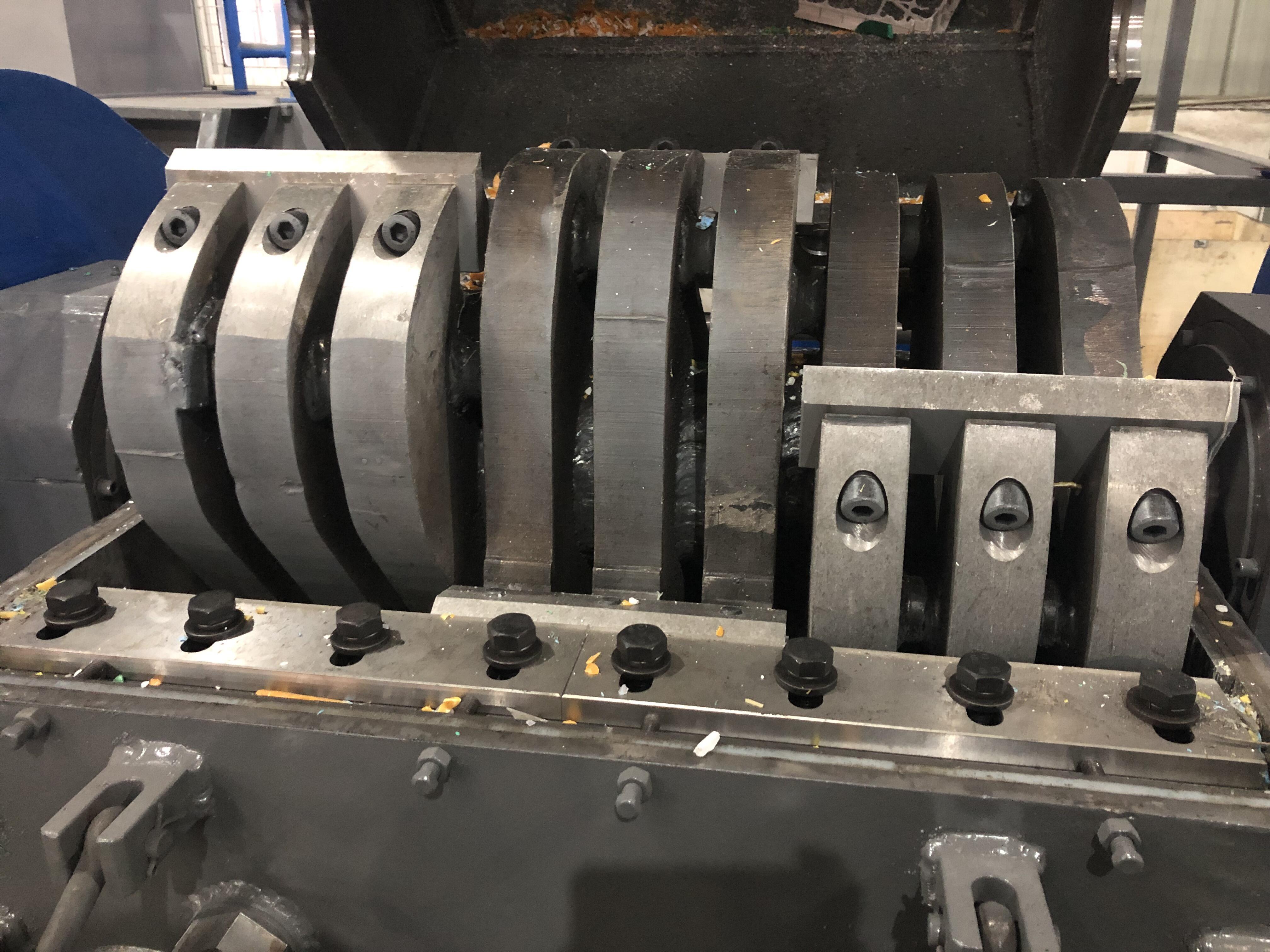

9. Special designed cross-type cutter structure ensure high capacity and low power consumption.

Model |

S-600 |

S-800 |

S-1000 |

S-1200 |

S-1500 |

Rotor Blade |

8 |

8 |

8 |

8 |

8 |

Fixed Blade |

4 |

4 |

4 |

4 |

4 |

Screen |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

Power |

30KW |

37/45KW |

45/55KW |

55/75KW |

75/90KW |

Capacity |

300kg/h |

500kg/h |

800-1000kg/h |

1000-1500kg/h |

1500-2000kg/h |

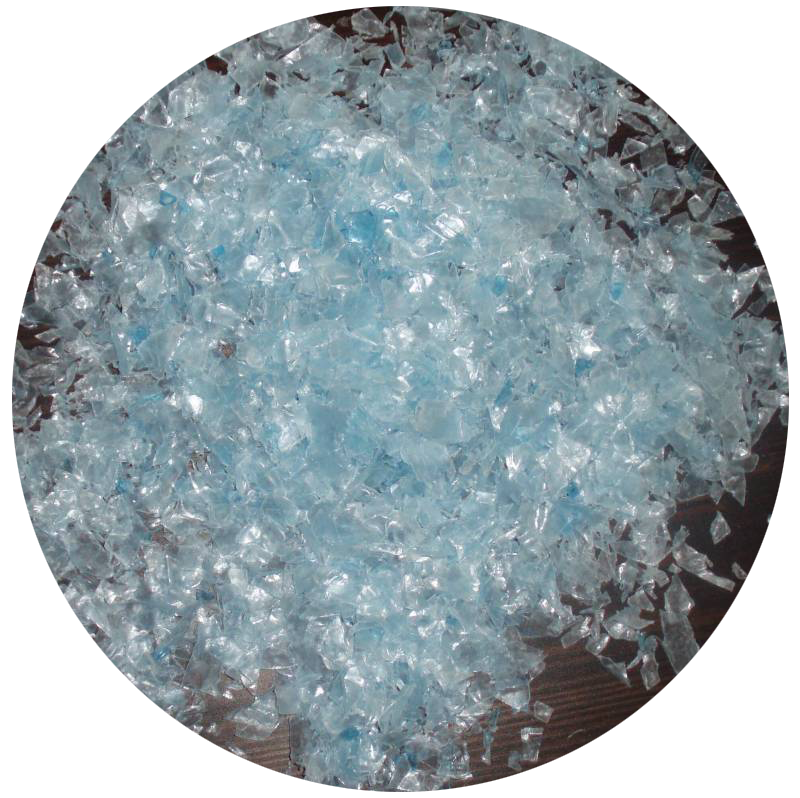

Final materialCrushed into flakes .

Fixed Blade: The blades more wider can sharpening 20-25 times, it will save the blade cost. Mateial: 9Crsi/SKD-11/D2.

Rotor: With strong rotor made and shaft.

Shaft made by 45#steel with quenching treatment.

Crusher Screen: Mesh diameter:14mm,

Mesh thickness:10mm

Motor: Make the motor performance good and can be used for a long time.

Used in PET bottle recycling washing line

Used in HDPE bottle recycling washing line

TURNKEY AFTER-SERVICE:

We send the engineers to help installing, commissioning and training.

• Pre sale: we give our client the detailed technician offer, sign the sales contract etc.

• In sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

FAQ:

Q: How long is the warranty time of the machine?

A: One year for free

Q: What material is the machine made of?

A: Stainless steel and carbon steel.

Q: Are your manufacturer or trading company?

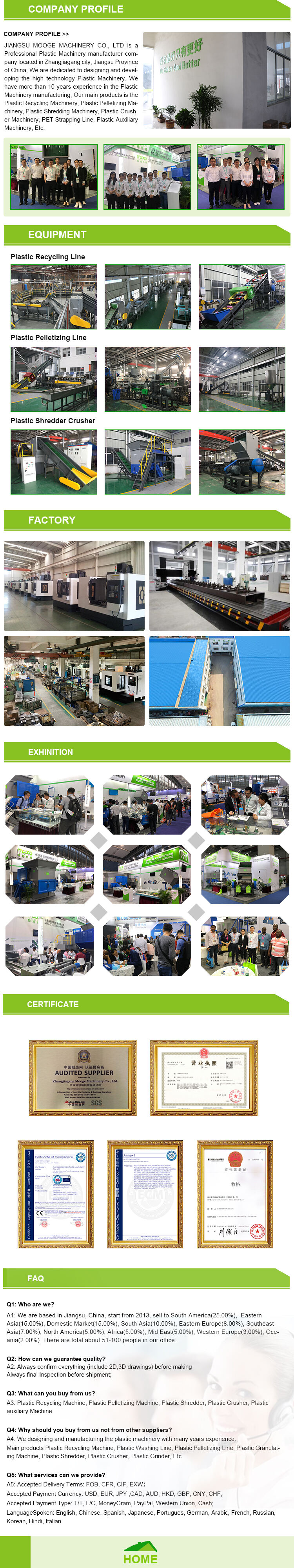

A: We are a professional plastic machinery manufacturer company located in ZHANGJIAGANG City, Jiangsu Province of China.

In order to have a better understanding of your needs, we need you to provide below information about your product:

1. Which kind of material you are going to process?

2. What is your required production capacity?

3. Do you have any other recycling machines?

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN