S Series - For PET/PP/PE/HDPE Bottles, Buckets, Hollow Containers, Plastic Crusher

Used for the PET bottle, Plastic Bottle, Buckets, Hollow Containers, and so on Plastic.

Its With Special Structure Design, Will Have More Capacity With Less Power Consumption.

Main Features:

1. Frame is made by solid square tube steel.

2. Shaft is made by 45# steel with quenching treatment.

3. Chamber is made by solid steel 40 mm thickness.

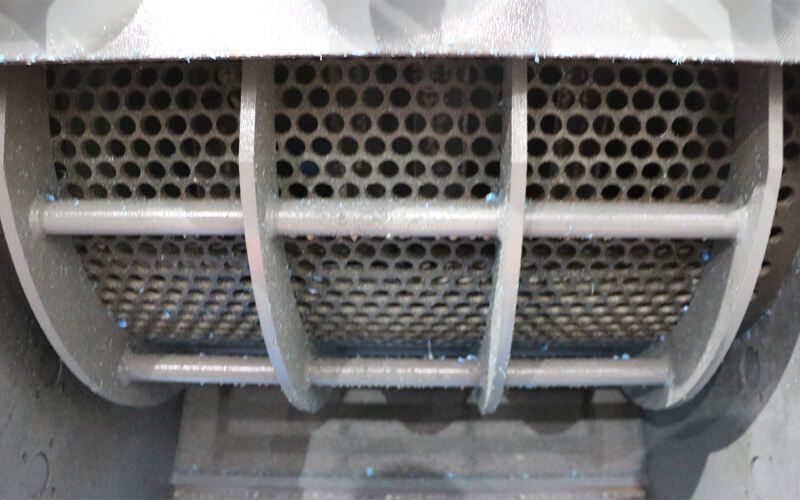

4. Screen mesh is made by 10 mm thick steel for durable use.

5. Easy-disassembling design, chamber is opened by motor automatically, which is simple and labor-saving to clean and maintain, and also convenient to change the blades.

6. Bearing house installed outside of the crusher chamber so no dirty goes inside which prolong the lifespan.

7. Machine upside chamber is higher and covered by belt no flakes popped out.

8. Blades are made by famous brand SKD-II from Japan with top quality.

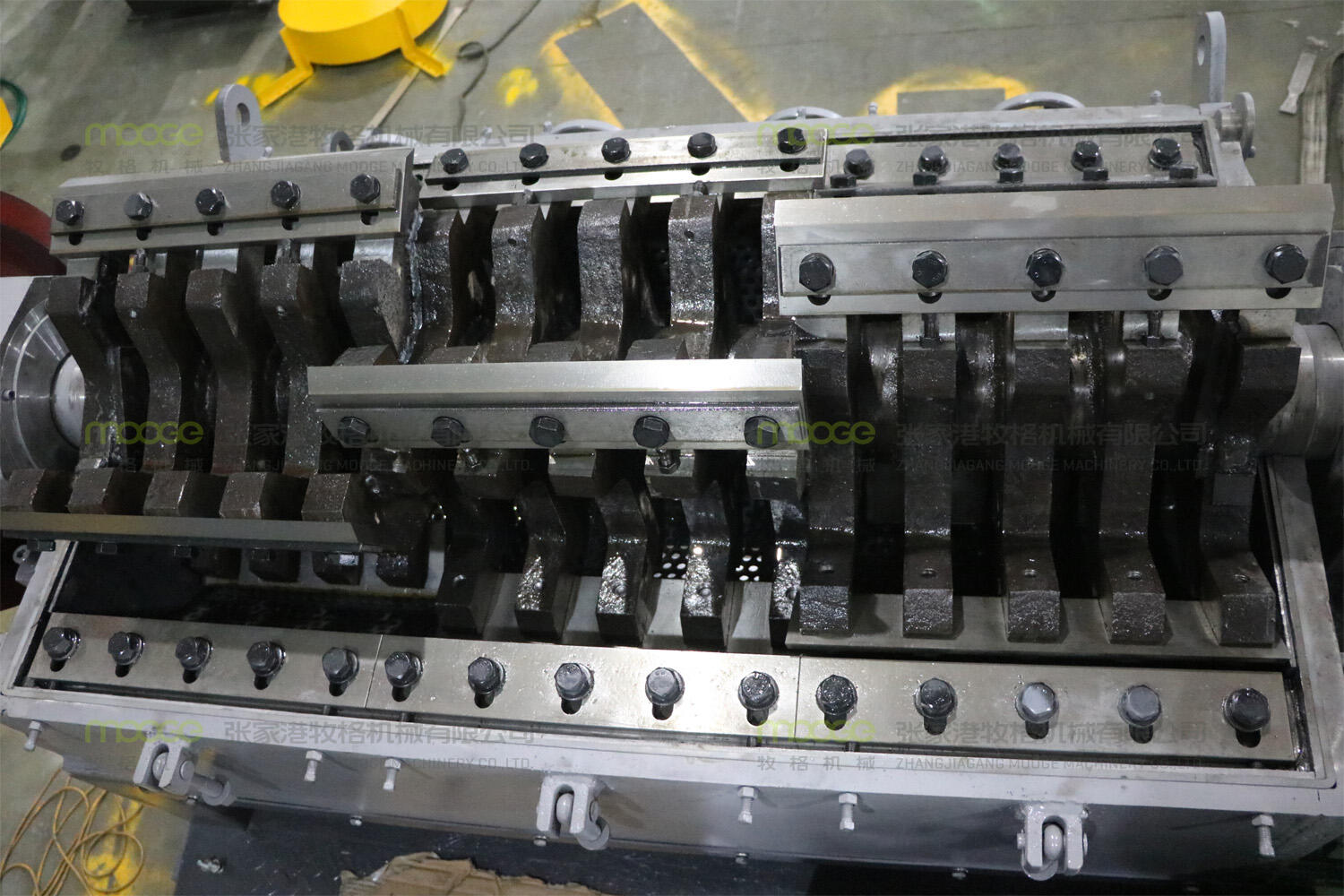

9. Special designed cross-type cutter structure ensure high capacity and low power consumption.

Model |

S-600 |

S-800 |

S-1000 |

S-1200 |

S-1500 |

Rotor Blade |

8 |

8 |

8 |

8 |

8 |

Fixed Blade |

4 |

4 |

4 |

4 |

4 |

Screen |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

Power |

30KW |

37/45KW |

45/55KW |

55/75KW |

75/90KW |

Capacity |

300kg/h |

500kg/h |

800-1000kg/h |

1000-1500kg/h |

1500-2000kg/h |

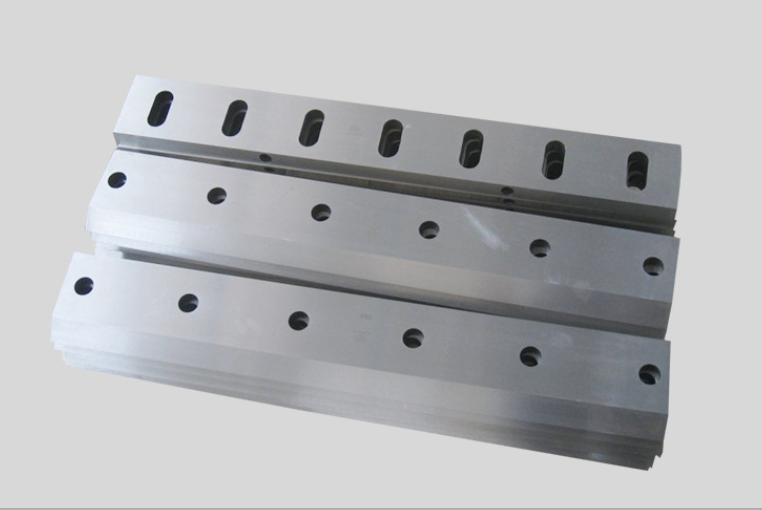

Fixed Blade: The blades more wider can sharpening 20-25 times, it will save the blade cost. Mateial: 9Crsi/SKD-11/D2.

Rotor: With strong rotor made and shaft.

Shaft made by 45#steel with quenching treatment.

Crusher Screen: Mesh diameter:14mm,

Mesh thickness:10mm

Motor: Make the motor performance good and can be used for a long time.

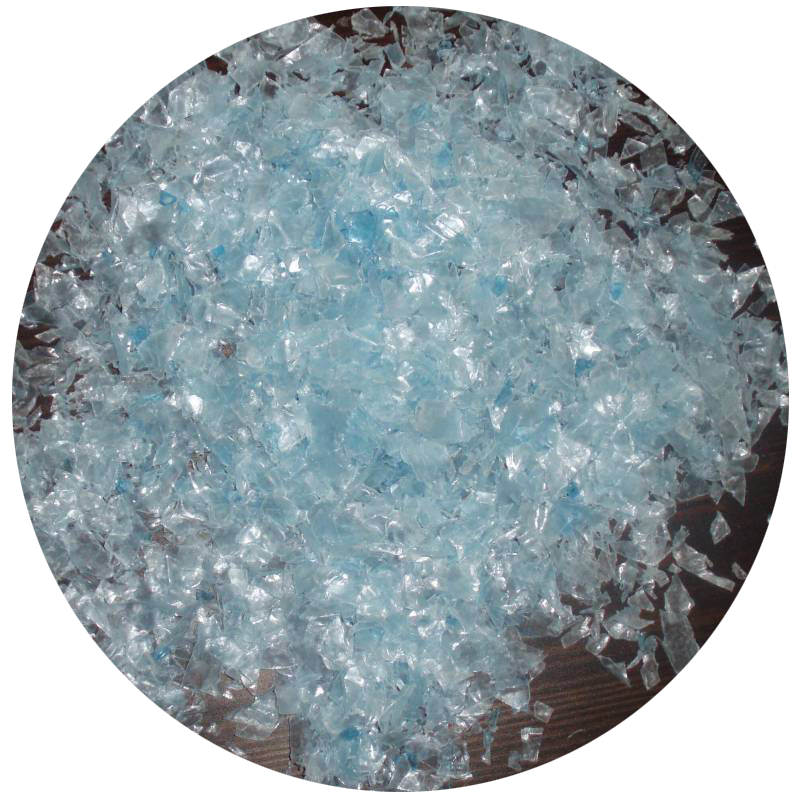

Final materialCrushed into flakes .

Used in PET bottle recycling washing line

Used in HDPE bottle recycling washing line

S-1200 Crusher Machine In Malaysia

S-1500 Crusher Machine In Algeria

S-1500 Crusher Machine In Russia

⢠Pre sale: we give our client the detailed technician offer, sign the sales contract etc.

⢠In sales: we supply the details layout, installation instruction, and technician support for the clients.

⢠After sales: we arrange engineer to install the machine and train the workers for our client.

⢠We have 24 hours service line to solve the after sales problem.

⢠We have free spare parts with the machine.

⢠We supply long term spare parts for every customer.

⢠We always update the new technology to every customer.

MOOGE

Bottle Crusher Machine is simply a cutting-edge product which's been built to effectively crush and recycle waste PET containers. The apparatus is effective at crushing containers made of a number of materials HDPE is including PP plastic, ABS, PC, and PET.

Made for both little and scale is operations which can be large may effectively handle up to 1200 containers each hour. It is made by having an engine is helpful can efficiently crush the bottles into small pieces in only a matter of moments.

One of many element is main the fact that it is rather efficient and easy to make use of. Operators simply require to feed the containers in the machine plus the machine does the others. The crushed items of plastic are then gathered in a container that may be effortlessly emptied and removed.

An additional benefit associated is strictly how it will make it possible to reduce air and waste pollution. The apparatus efficiently processes the bottles into smaller pieces you are able to again use once as raw materials for different processes which are manufacturing thereby decreasing the impact is environmental by plastic waste.

Very durable and easy to steadfastly keep up. It’s made materials which are using are top-quality can withstand the rigors of commercial usage. Also, the apparatus requires upkeep is minimal operators which are often allowing attention is given their core business tasks rather than worrying all about machine breakdowns.

The MOOGE Bottle Crusher Machine is simply a recycling is high-performances perfect for both small and big scales operations are recycling. It really highly efficient, very easy to utilized, eco-friendly, durable, and low-maintenance. The goods is supported by a good reputations for quality and reliability, that makes it a fantastic choices for anyone trying to find a dependable, effective treatment for their plastics recycling needs.

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN