MOOGE

30KW इंडस्ट्रियल हार्ड PET बॉटल कचरा प्लास्टिक क्रशर मशीन ऐसे किसी भी व्यापारिक प्रक्रिया के लिए जीवंत उपकरण है जो मानव-बनाई कचरे से सम्बंधित है। यह उपकरण कुशलतापूर्वक सबसे कठिन प्लास्टिक सामग्री को टूटा सकता है, जिसमें जानवरों के हार्ड को छोटे-छोटे टुकड़ों में बदल दिया जाता है जो पुन: उपयोग किए या हटाए जा सकते हैं।

इस उपकरण का निर्माण MOOGE उत्कृष्ट सामग्रियों से किया गया है जो भारी व्यापारिक स्थानों में उपयोग को सहन कर सकती है। क्रशर का मुख्य शरीर घनत्वपूर्वक धातु से बना है, जो इसकी अवधारणा और सुरक्षा को गारंटी देता है। चाकूएं उच्च-ग्रेड स्टेनलेस से बनी हैं, जो साबुन और जंग से प्रतिरोधी हैं, एक स्थिर उपकरण जीवन की गारंटी देती है।

30KW क्षमता वाला इंजन सबसे कठिन प्लास्टिक को आसानी से टूटा सकता है। इंजन को अधिकतम प्रभावशीलता पर काम करने के लिए डिज़ाइन किया गया है, जो बिजली की खपत को कम करता है और कुशलता बढ़ाता है।

30KW इंडस्ट्रियल हार्ड PET बोतल कचरा प्लास्टिक क्रशर मशीन आपकी सुरक्षा को ध्यान में रखकर बनाई गई है। यह उपकरण कई सुरक्षा विशेषताओं से युक्त है, जिसमें एक आपातकालीन स्थगित कुंजी और एक पता सुरक्षित अविष्कार शामिल है जो ब्लेडों पर गलत रूप से छूने से बचाता है।

इस उत्पाद को चलाना आसान है, एक सरल कंट्रोल सिस्टम के साथ जिससे आप आवश्यकतानुसार गति और अन्य सेटिंग्स को समायोजित कर सकते हैं। इस उत्पाद का संपाट डिज़ाइन इसे किसी भी औद्योगिक परिवेश में आसानी से लगाया जा सकता है, जिससे कम स्थान लगता है लेकिन अधिकतम कार्यक्षमता प्रदान करता है।

30KW इंडस्ट्रियल हार्ड PET बोतल कचरा प्लास्टिक क्रशर मशीन अपनी उच्च कार्यक्षमता, स्थायित्व और सुरक्षा विशेषताओं के साथ प्रत्येक औद्योगिक प्रक्रिया के लिए एक आदर्श समाधान है। यह उत्पाद यह सुनिश्चित करता है कि प्लास्टिक कचरा सही ढंग से फेंका या पुन: उपयोग किया जाए, जिससे पर्यावरण पर प्रभाव कम हो और कचरा फेंकने से जुड़े खर्चों को कम किया जा सके।

30KW इंडस्ट्रियल हार्ड PET बोतल कचरा प्लास्टिक क्रशर मशीन खरीदना भविष्य में व्यापार और पर्यावरण के लिए एक अच्छा निवेश हो सकता है। यह उत्पाद अंतिम तरीके से बनाया गया है, जिससे आपकी प्रक्रिया दशकों तक फलदायी होगी जबकि इसका कार्बन प्रभाव और पर्यावरणिक प्रभाव कम होगा।

S सीरीज प्लास्टिक क्रशर - PET/PP/PE/HDPE बोतलों, बकेट, खोखले कंटेनर के लिए।

PET बोतल, प्लास्टिक बोतल, बकेट्स, खोखले कंटेनर्स और इसी तरह के प्लास्टिक के लिए।

इसका विशेष संरचना डिज़ाइन है, जिससे कम ऊर्जा खपत के साथ अधिक क्षमता होगी।

मुख्य विशेषताएं:

1. फ़्रेम मजबूत स्क्वायर ट्यूब स्टील से बना है।

2. धुरी 45# स्टील से बनी है और क्वेन्चिंग उपचार से युक्त है।

3. चेम्बर मजबूत 40 मिमी मोटाई की स्टील से बना है।

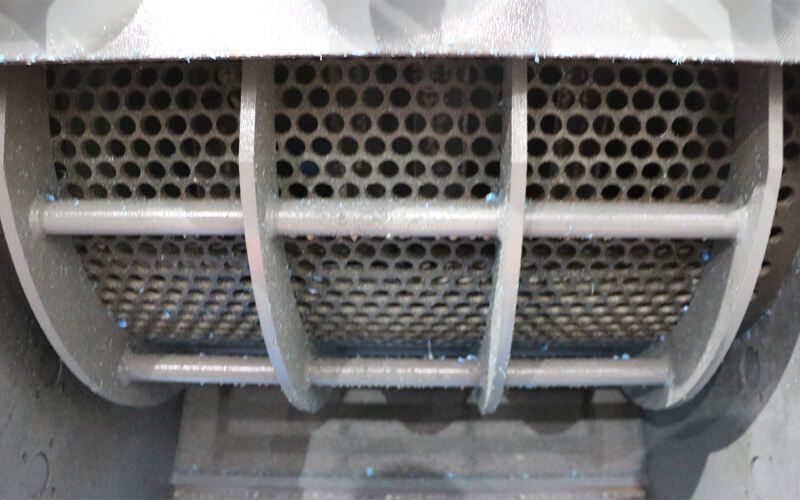

4. स्क्रीन मेश 10 मिमी मोटी स्टील से बना है, जो दूरदराज़ उपयोग के लिए है।

5. आसान-वियोजन डिज़ाइन, चेम्बर मोटर द्वारा स्वचालित रूप से खुलता है, जो सफाई और रखरखाव करने में सरल और श्रम-बचाव है, और ब्लेड बदलने में भी सुविधाजनक है।

6. बेयरिंग हाउस क्रशर चेम्बर के बाहर लगाया गया है ताकि अंदर कोई गंदगी न जाए, जिससे उसकी जीवनकाल बढ़ जाती है।

7. मशीन का ऊपरी चेम्बर अधिक ऊँचा है और बेल्ट से ढका है, ताकि कोई टुकड़े बाहर न निकलें।

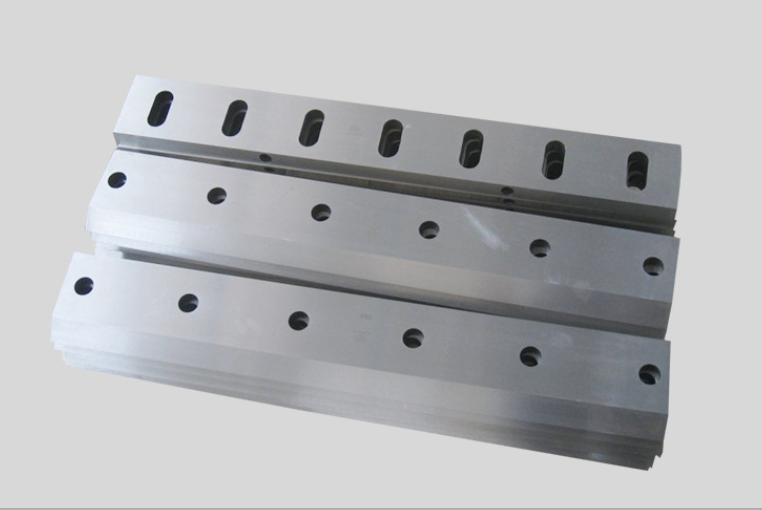

8. चादरें जापान के प्रसिद्ध ब्रैंड SKD-II द्वारा बनाई गई हैं, जो सर्वोत्तम गुणवत्ता की हैं।

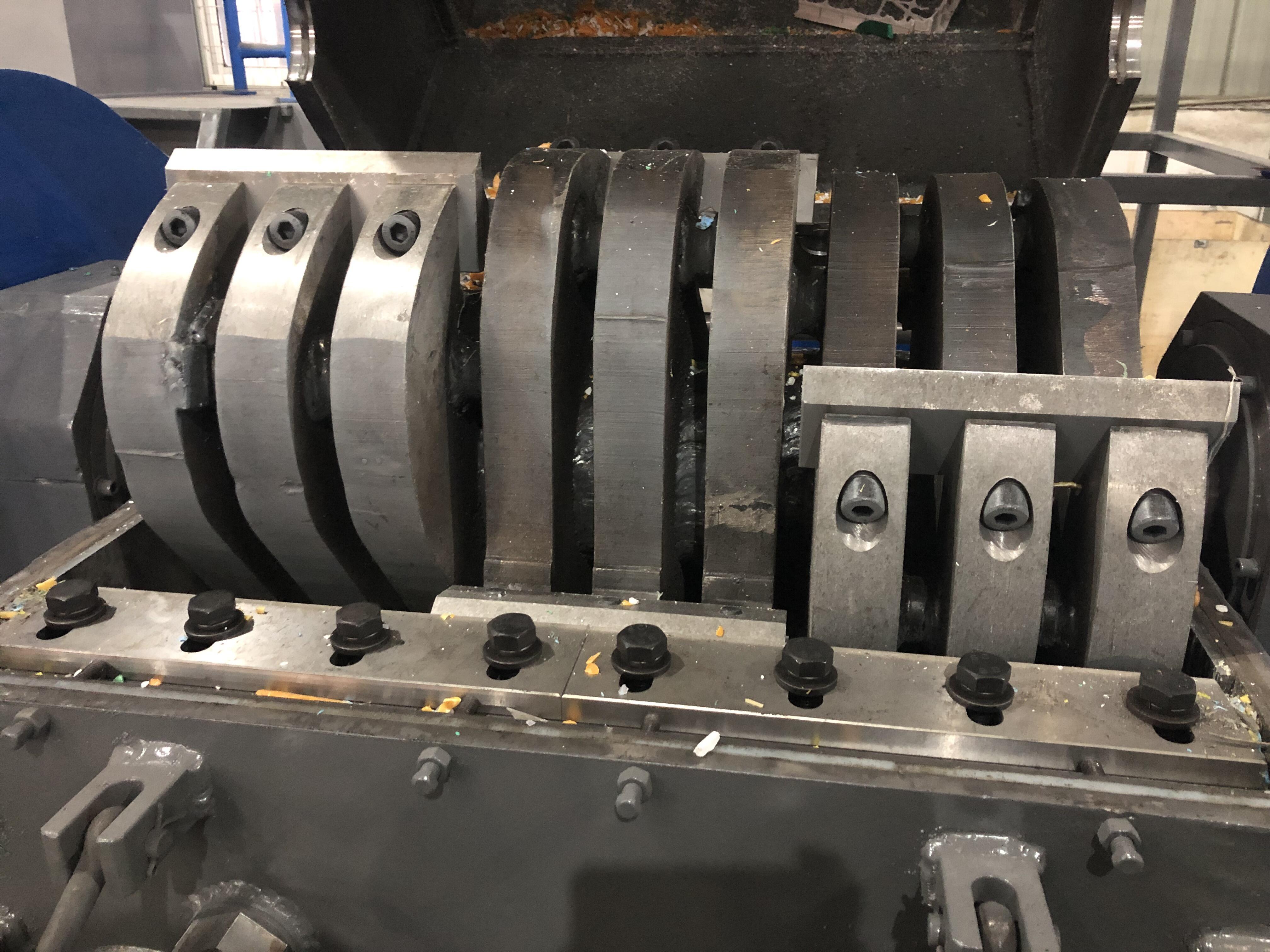

9. विशेष डिज़ाइन क्रॉस-टाइप कटर स्ट्रक्चर उच्च क्षमता और कम ऊर्जा खपत को सुनिश्चित करती है।

मॉडल |

एस 600 |

S-800 |

S-1000 |

S-1200 |

S-1500 |

रोटर चादर |

8 |

8 |

8 |

8 |

8 |

फिक्स्ड चादर |

4 |

4 |

4 |

4 |

4 |

स्क्रीन |

14/16 मिमी |

14/16 मिमी |

14/16 मिमी |

14/16 मिमी |

14/16 मिमी |

शक्ति |

30 किलोवाट |

37/45KW |

45/55KW |

55/75KW |

75/90KW |

क्षमता |

300kg/ h |

500 किलोग्राम/घंटा |

800-1000किलोग्राम/घंटा |

1000-1500किलोग्राम/घंटा |

1500-2000किलोग्राम/घंटा |

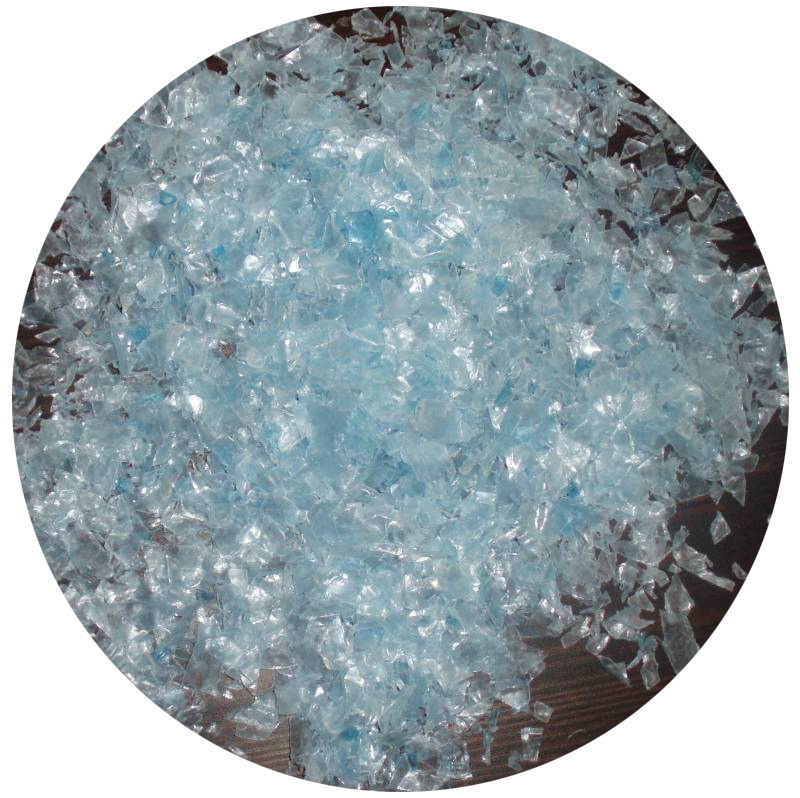

अंतिम सामग्री फ्लेक्स में दमित।

निर्धारित चाकू: चादरें अधिक चौड़ी हो सकती हैं और 20-25 बार तीखा किया जा सकता है, यह चादर की लागत कम करेगा। मटेरियल: 9Crsi/ SKD-11/ D2।

चक्री: मजबूत रोटर और शाफ्ट के साथ बनाया गया।

शाफ्ट 45#स्टील से बना है और क्वेन्चिंग उपचार किया गया है।

क्रशर स्क्रीन: जाल व्यास: 14mm,

जाल की मोटाई: 10mm

मोटर: मोटर की प्रदर्शन अच्छी रहती है और इसे लंबे समय तक उपयोग किया जा सकता है।

PET बोतल रीसाइकलिंग धोने लाइन में उपयोग किया जाता है।

HDPE बोतल रीसाइकलिंग धोने लाइन में उपयोग किया जाता है।

टर्नकी बाद का सेवा:

हम इंजीनियरों को मदद करने के लिए भेजते हैं, इनस्टॉल करने, कमिशनिंग और प्रशिक्षण में।

• पूर्व बिक्री: हम अपने ग्राहक को विस्तृत तकनीशियन ऑफ़र देते हैं, बिक्री ठेके को हस्ताक्षर करते हैं आदि।

• बिक्री के दौरान: हम ग्राहकों को विवरण लेआउट, इनस्टॉलेशन निर्देश, और तकनीशियन समर्थन प्रदान करते हैं।

• बाद की बिक्री: हम अपने ग्राहक के लिए इंजीनियर व्यवस्थित करते हैं ताकि वे मशीन को इनस्टॉल करें और कामगारों को प्रशिक्षित करें।

• हमारे पास सेवा लाइन के 24 घंटे की योजना है जो बाद की बिक्री समस्या को हल करती है।

• हमारे पास मशीन के साथ मुफ्त रिज़र्व पार्ट्स हैं।

• हम प्रत्येक ग्राहक के लिए लंबे समय तक रिज़र्व पार्ट्स प्रदान करते हैं।

• हम हर ग्राहक को नई तकनीक का अपडेट करते रहते हैं।

सामान्य प्रश्न:

प्रश्न: मशीन का गारंटी समय कितना है?

A: एक साल का मुफ्त

Q: मशीन किस पदार्थ से बनी है?

A: स्टेनलेस स्टील और कार्बन स्टील।

प्रश्न: क्या आप विनिर्माण कंपनी हैं या व्यापार कंपनी?

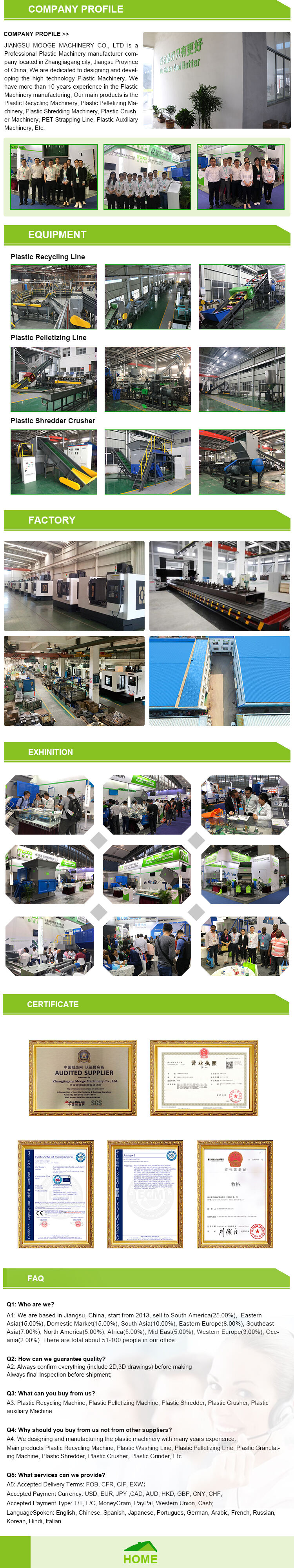

A: हम एक प्रोफेशनल प्लास्टिक मशीनरी निर्माता कंपनी हैं जो चीन के जियांगसू प्रांत के ZHANGJIAGANG शहर में स्थित है।

आपकी आवश्यकताओं को बेहतर ढंग से समझने के लिए, हमें आपको अपने उत्पाद के बारे में नीचे दी गई जानकारी प्रदान करनी होगी:

1. आप किस प्रकार के पदार्थ को प्रोसेस करने वाले हैं?

2. आपकी आवश्यकता के अनुसार उत्पादन क्षमता क्या है?

3. क्या आपके पास कोई अन्य रिक़ायक़ मशीनें हैं?

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN